Method for extracting S30432 steel carbonitride with electrolytic method

A technology of carbonitride and electrolysis, applied in the field of electrochemical technology, can solve the problems of lack of statistical representativeness, cumbersome and time-consuming methods, etc., and achieve the effects of facilitating activation and dissolution, high extraction rate, and easy washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

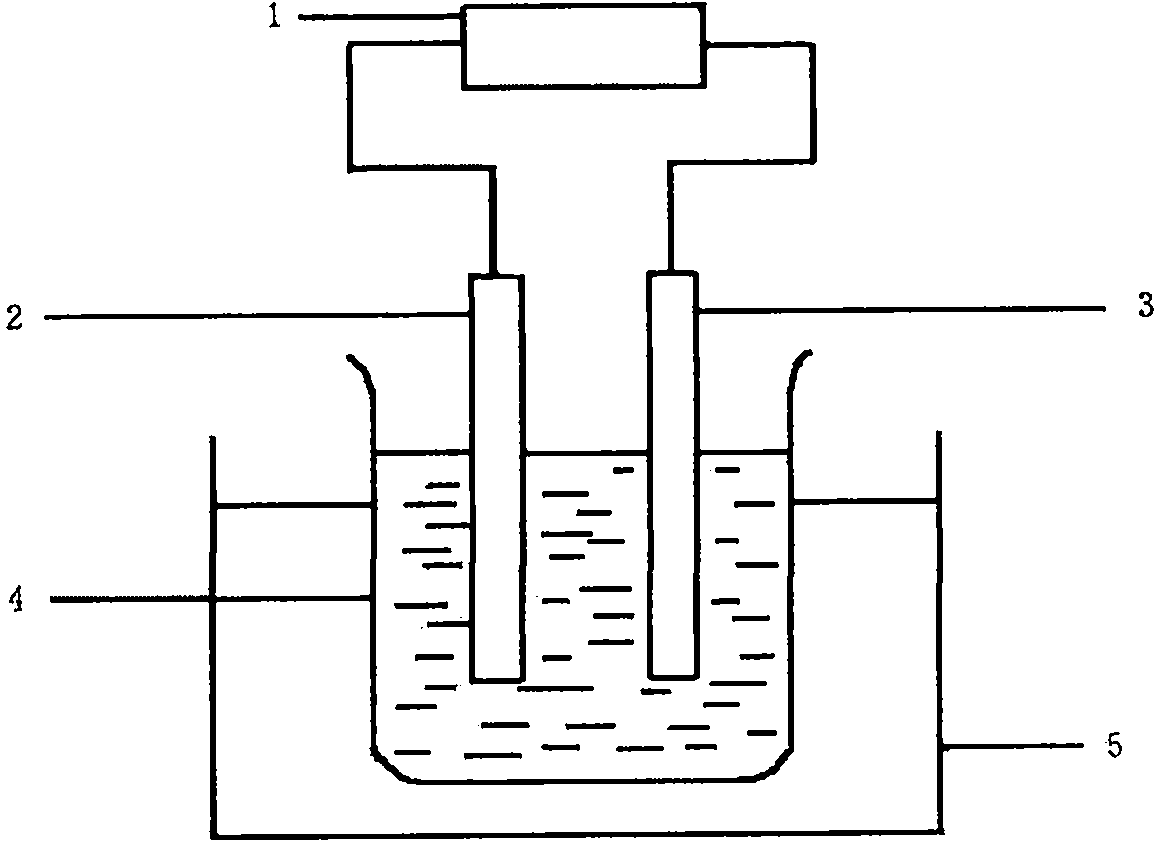

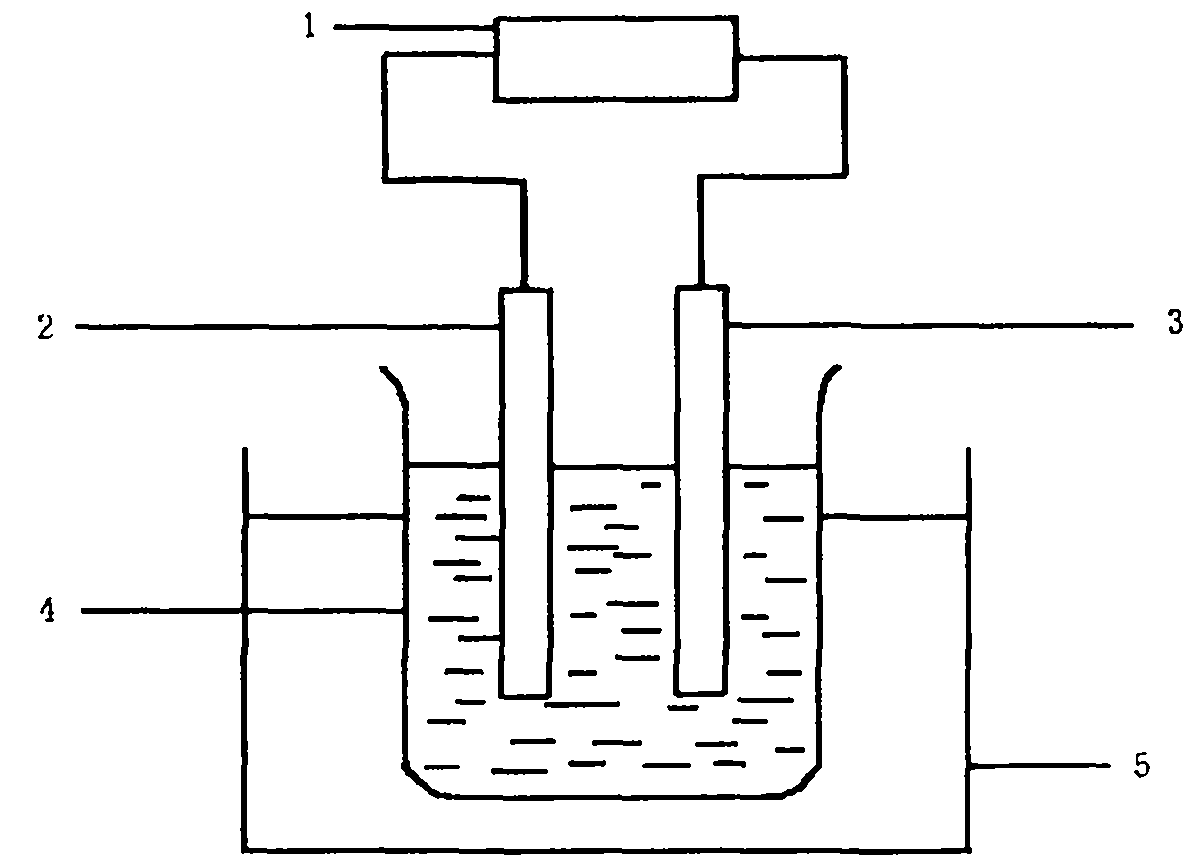

[0021] Embodiment 1: First prepare the electrolyte solution, the electrolyte solution formula is as follows (wt%): tetramethylammonium chloride 1%, acetylacetone 10%, methanol (analytical pure) 89%.

[0022] Put the above electrolyte into the electrolytic cell, polish and clean the supplied S30432 steel sample (5×10×80mm) and put it into the electrolytic cell as the anode, and the sheet-shaped platinum electrode as the cathode, and control the current density to 25mA / cm 2 , constant current electrolysis for 8h; keep the temperature at 0°C.

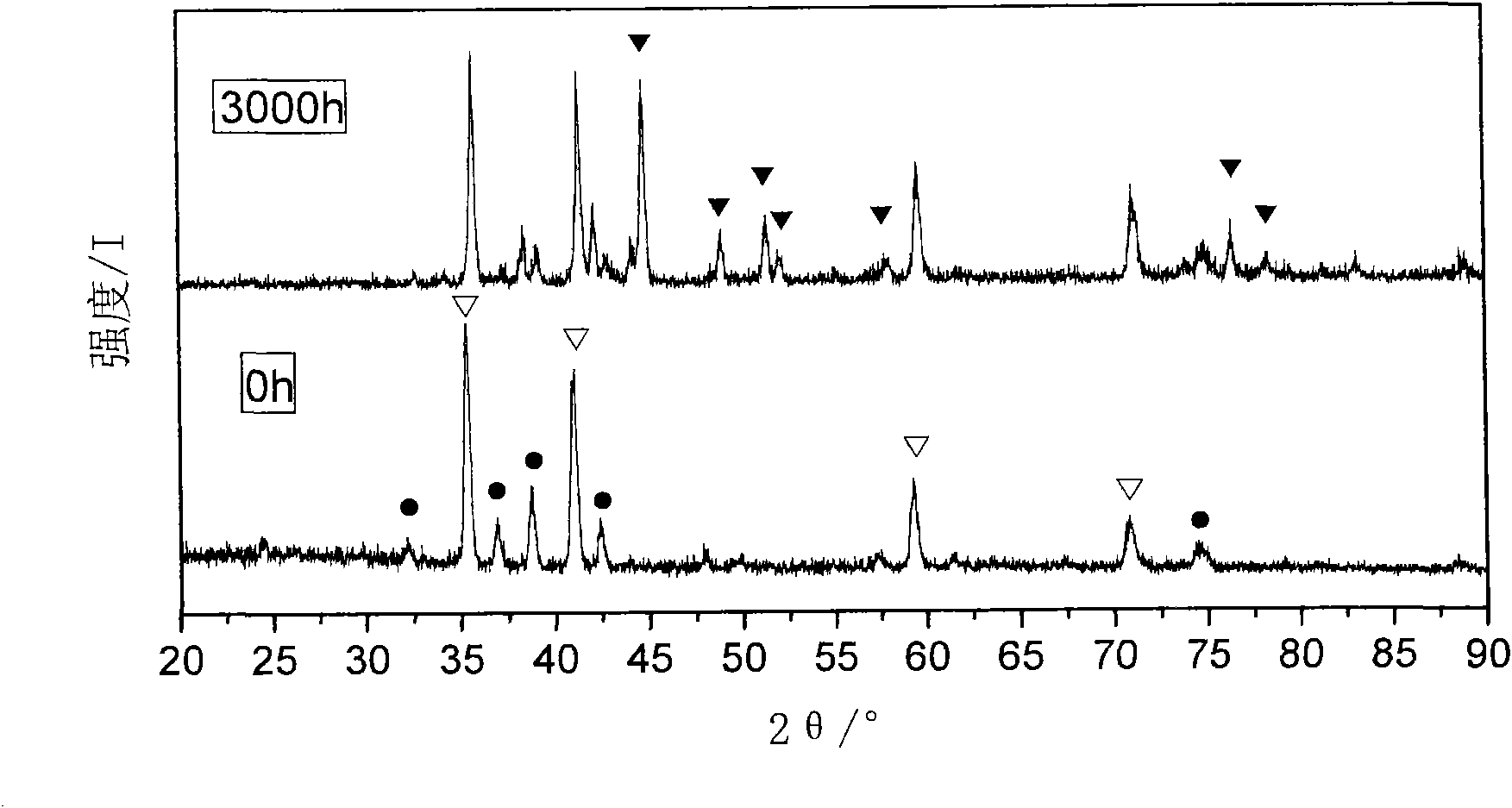

[0023] Then put the above electrolytic solution into a vacuum separation and filtration device equipped with a polycarbonate filter membrane with a pore size of 50nm, and separate the precipitates under a vacuum state, and dry them for more than 24 hours. Weigh, and calculate the carbonitride mass fraction to be 0.73%. XRD pattern analysis shows that NbC and NbN are found.

Embodiment 2

[0024] Embodiment 2: This embodiment is basically the same as Embodiment 1. The difference is: the S30432 heat-resistant steel sample (5×10×80mm) aged at 650°C for 3000h is polished and cleaned and placed in the electrolytic cell as the anode, and the sheet-shaped platinum electrode as the cathode, and the current density is controlled at 25mA / cm 2 , constant current electrolysis for 8h; keep the temperature at 0°C.

[0025] Then put the above electrolytic solution into a vacuum separation and filtration device equipped with a polycarbonate filter membrane with a pore size of 50 nm, and separate the carbonitrides in a vacuum state, and dry for more than 24 hours. Weigh and calculate the carbonitride mass fraction to be 1.5%. XRD pattern analysis shows that carbonitrides include NbC, NbN and M 23 C 6 . This is because the sample treatment conditions used in this example are different from Example 1, the mass fraction of carbonitrides increases, corresponding to a new carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com