Hollow porous membrane and process for producing the same

A technology for porous membranes and manufacturing methods, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of reduced separation characteristics, problems in production costs, and the inability of two layers to be fully integrated, so as to reduce costs, mechanical Excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0251] (manufacture of support)

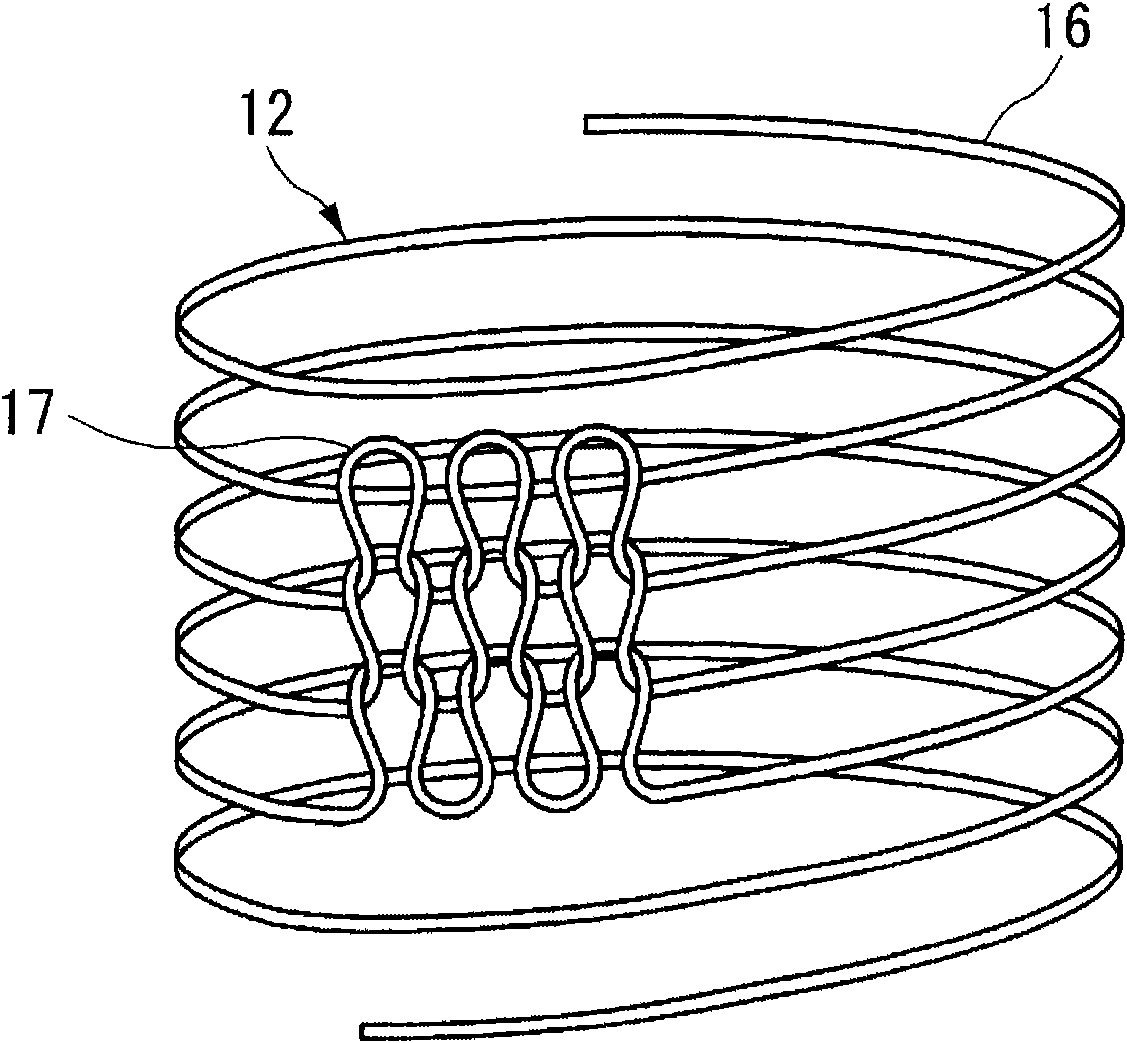

[0252] use Figure 6 The shown support body manufacturing apparatus 20 manufactures the support body 10 which consists of the hollow knitted string 12. As shown in FIG.

[0253] As the yarn, polyester fiber (denier: 84 dtex, number of filaments: 36) was used. As the bobbin 22, five bobbins wound with 5 kg of the above-mentioned polyester fiber were prepared. As the circular knitting machine 24 , a desktop circular knitting machine (manufactured by Yuanjing Textile Machinery Co., Ltd., number of latch needles: 12, needle size: 16 gauge, and spindle diameter: 8 mm) was used. As the rope supply device 26 and the recovery device 30, Nelson rollers are used. As the heating die 28 , a stainless steel die (inner diameter D: 5 mm, inner diameter d: 2.2 mm, length: 300 mm) having a heating device was used.

[0254] The polyester fibers drawn from the five bobbins 22 are gathered into one as the yarn 16 (the total fineness is 420dtex), and then circ...

Embodiment 2

[0280] (Manufacture of hollow porous membrane)

[0281] The hollow porous membrane 1 was produced in the same manner as in Example 1 except that only the membrane-forming stock solution (1) was applied to the outer peripheral surface of the support 10 in the first annular nozzle 42 .

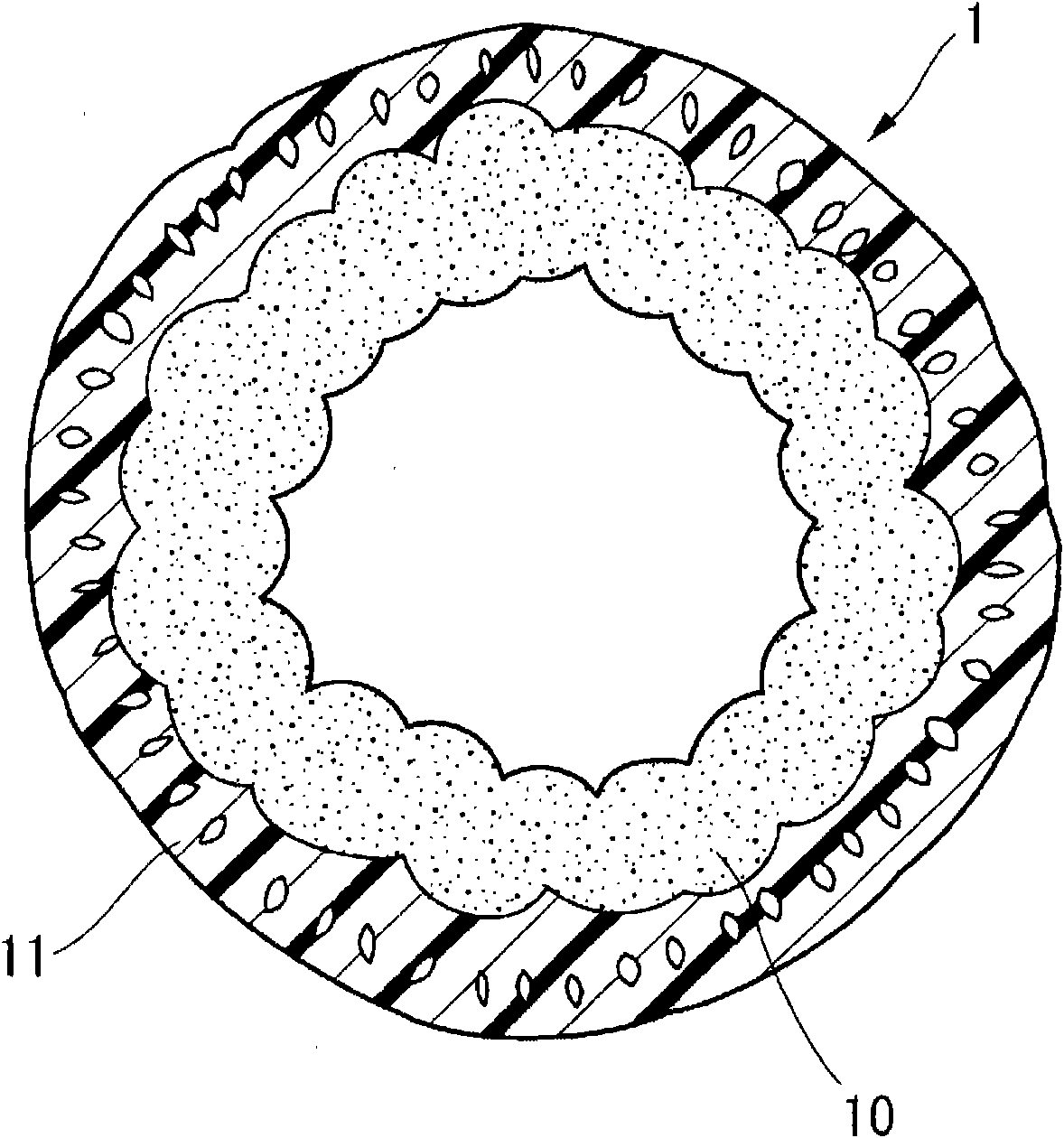

[0282] The obtained hollow porous membrane 1 has an outer diameter of about 2.78 mm, an inner diameter of about 1.2 mm, an average thickness of the porous membrane layer 11 of about 340 μm, a bubble point of 110 kPa, and a water permeability of 115 m 3 / m 2 / h / MPa.

[0283] The porous hollow fiber membrane was subjected to a peeling resistance test. As a result, the entire second layer of the porous hollow fiber membrane was peeled off from the first layer and remained on the kraft tape. Partially carried out the same test, the entire first layer part was not peeled off from the support, and only a part of the first layer part epidermis remained on the kraft tape.

[0284] The hollow porous m...

Embodiment 3

[0286] In addition to Yarn 16, use polyester fiber A (denier: 84dtex, number of filaments: 72) and polyester fiber B (high tenacity polyester fiber, fineness: 235dtex, number of filaments: 24), and prepare one bobbin 22 A bobbin A wound with 5 kg of polyester fiber A and two bobbins B wound with 5 kg of polyester fiber B (the total fineness is 554 dtex), as the circular knitting machine 24, a desktop circular knitting machine (Circular Well Manufactured by Textile Machinery Co., Ltd., number of latch needles: 10, needle size: 16 gauge, and spindle circumference diameter: 10 mm), the support body 10 was produced in the same manner as in Example 1, up to the polyester fiber A without the bobbin A.

[0287] The obtained support 10 had an outer diameter of about 2.1 mm and an inner diameter of about 1.2 mm. The number of loops 17 of the hollow knitted rope 12 constituting the support 10 is 10 per turn, and the maximum opening width of the mesh 18 is about 0.15 mm. The length of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com