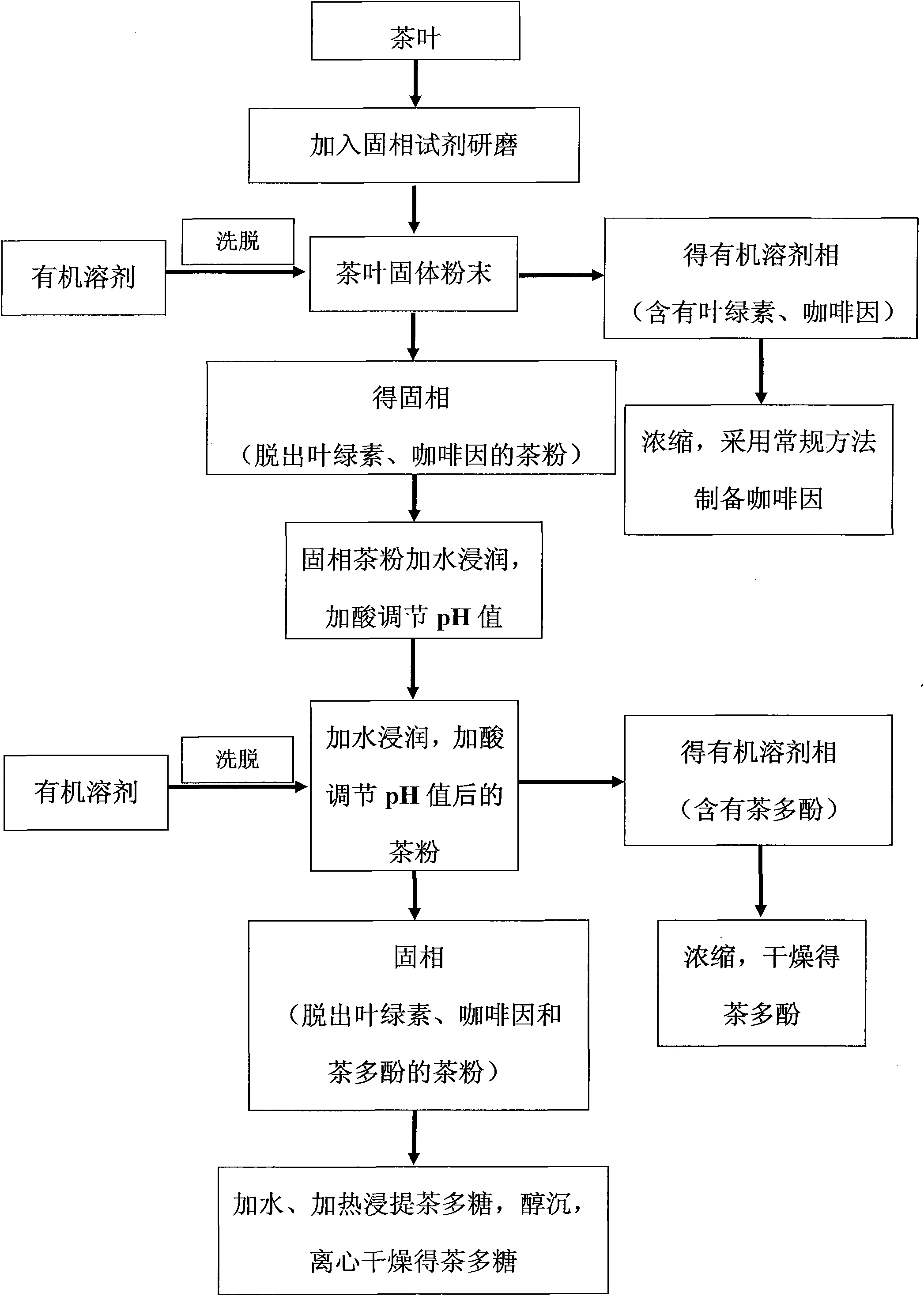

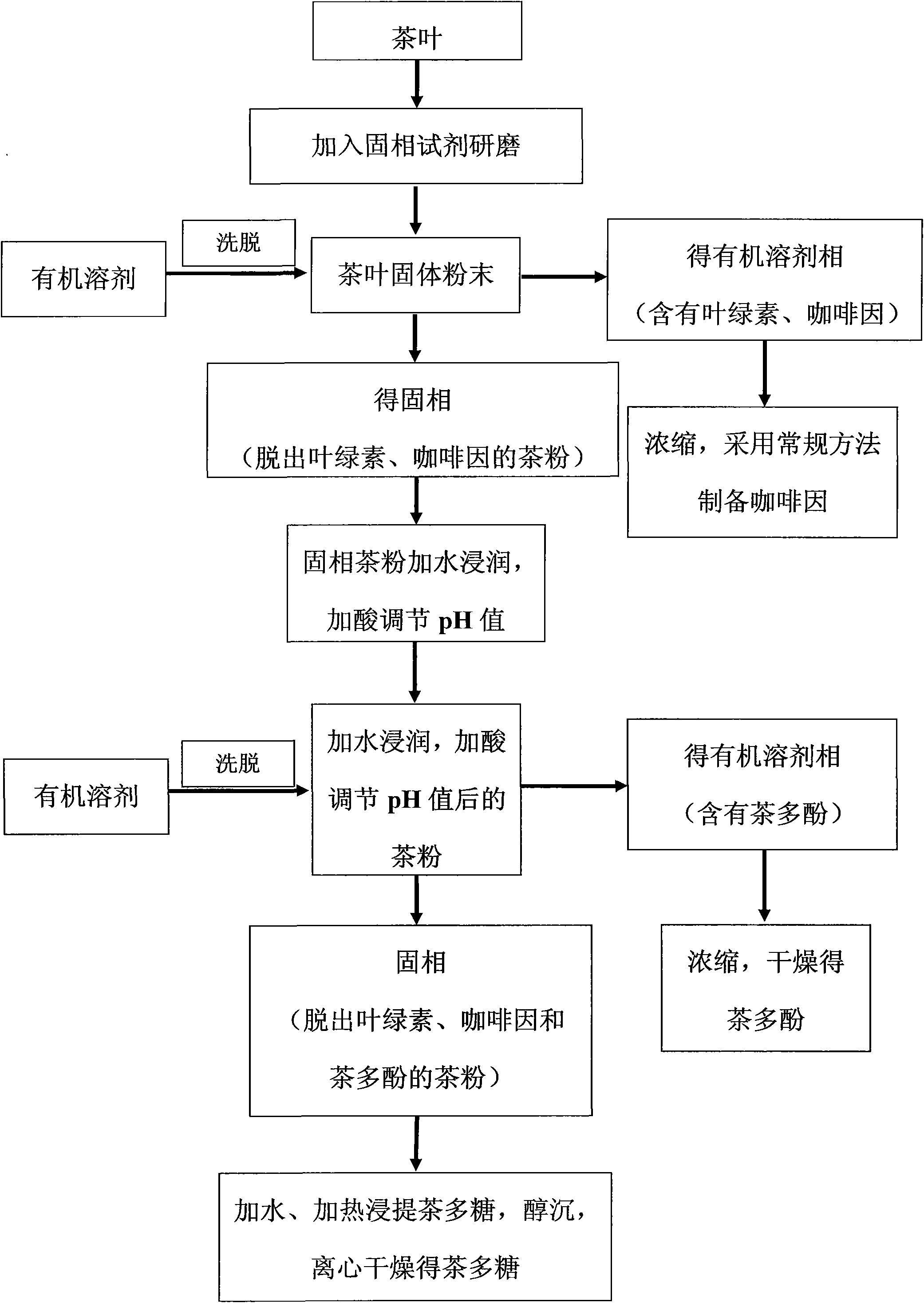

Novel method for simultaneously extracting caffeine, tea polyphenol and tea polysaccharide from tea using mechanochemical principle

A mechanochemical and caffeine technology, applied in the field of extracting caffeine, tea polyphenols and tea polysaccharides, to achieve the effects of improving purity, increasing yield and reducing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]At room temperature, mix 10 g of crushed tea leaves with 1 g of potassium carbonate and 0.2 g of sodium borate, and grind the mixture in a ball mill for 10 min; take out the ground powder, add 20 mL of chloroform to the mixed tea powder for 3 times, stir for 10 min each time, and filter , combined the chloroform phases obtained by 3 times of treatment, and concentrated to obtain a mixture of chlorophyll and caffeine. The mixture was prepared by sublimation method to obtain caffeine; 20 mL of water and 2 mL of phosphoric acid were added to the tea solids obtained by elution with chloroform to adjust the pH value to ≤7, and divided into 5 Add 20 mL of ethyl acetate to elute the tea solids again, stir for 10 min, filter, collect 5 times of ethyl acetate eluate, concentrate to obtain tea polyphenols; add 100 mL of water to the tea solids treated by the above steps, and heat to Keep warm at 100°C for 20min, filter, add 300mL of ethanol, let stand for 24h, collect the precipita...

Embodiment 2

[0048] At room temperature, mix 10g of crushed tea leaves with 1.2g of potassium silicate and 0.2g of sodium borate, and grind the mixture in a ball mill for 10 minutes; take out the ground powder, and add 20mL of petroleum ether-ethyl acetate to the mixed tea powder in 5 times (Volume ratio 1: 1) mixed solutions, stirred for 10min respectively, filtered, combined the petroleum ether-ethyl acetate phase obtained from five treatments, and concentrated to obtain a mixture of chlorophyll and caffeine, which was prepared by sublimation method to obtain caffeine; - Add 10mL of water and 2mL of phosphoric acid to the tea solids obtained by ethyl acetate elution, adjust the pH to ≤7, add 20mL of absolute ethanol in 5 times to elute the tea solids again, stir for 10min, filter, collect 5 times of ethanol mobile phase concentration , to get tea polyphenols; add 100mL of water to the tea solids that have been processed through the above steps, heat to 100°C and keep warm for 20min, filte...

Embodiment 3

[0050] At room temperature, mix 10 g of crushed tea leaves with 1 g of potassium bicarbonate and 0.2 g of sodium borate, and grind the mixture in a ball mill for 10 min; take out the ground powder, and add 20 mL of petroleum ether-chloroform (volume ratio 1:1) mixed solution, stirred for 10 min respectively, filtered, combined the obtained petroleum ether-chloroform phases after five treatments, and concentrated to obtain a mixture of chlorophyll and caffeine, which was prepared by sublimation method to obtain caffeine; obtained by eluting with petroleum ether-chloroform Add 10 mL of water and 2 mL of phosphoric acid to the tea solids to adjust the pH value to ≤7, add 20 mL of absolute ethanol in 5 times to elute the tea solids again, stir for 10 min, filter, collect 5 times of ethanol mobile phase concentration, and obtain tea polyphenols; Add 100mL of water to the tea solids treated in the above steps, heat to 100°C and keep warm for 20min, filter, add 300mL of ethanol, let s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com