Solar cell back panel, preparation method thereof and solar module

A technology for solar cells and backplanes, applied in electrical components, chemical instruments and methods, circuits, etc., can solve problems such as poor weather resistance, low adhesion, and non-environmental protection, and achieve strong weather resistance, high adhesion, and improved weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

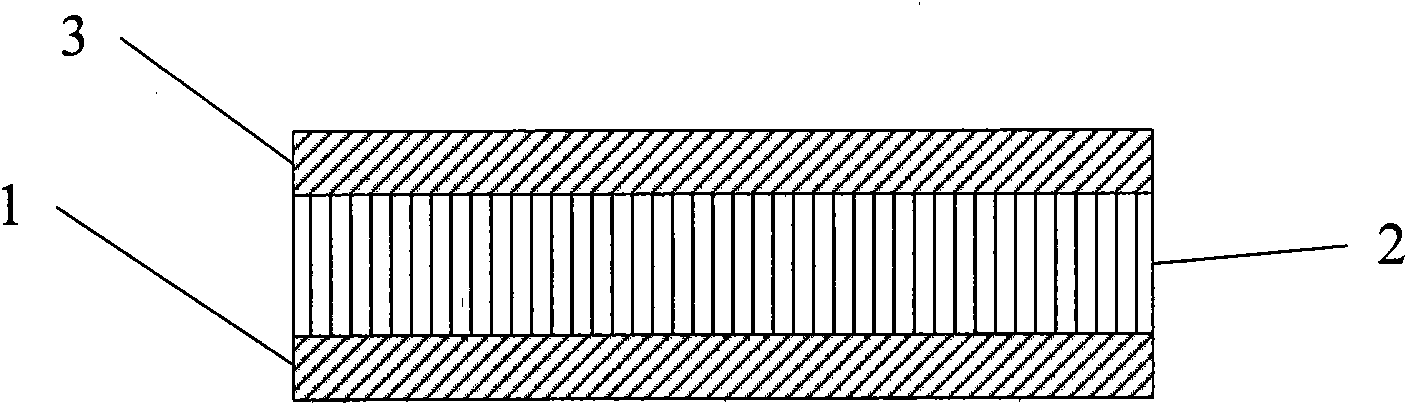

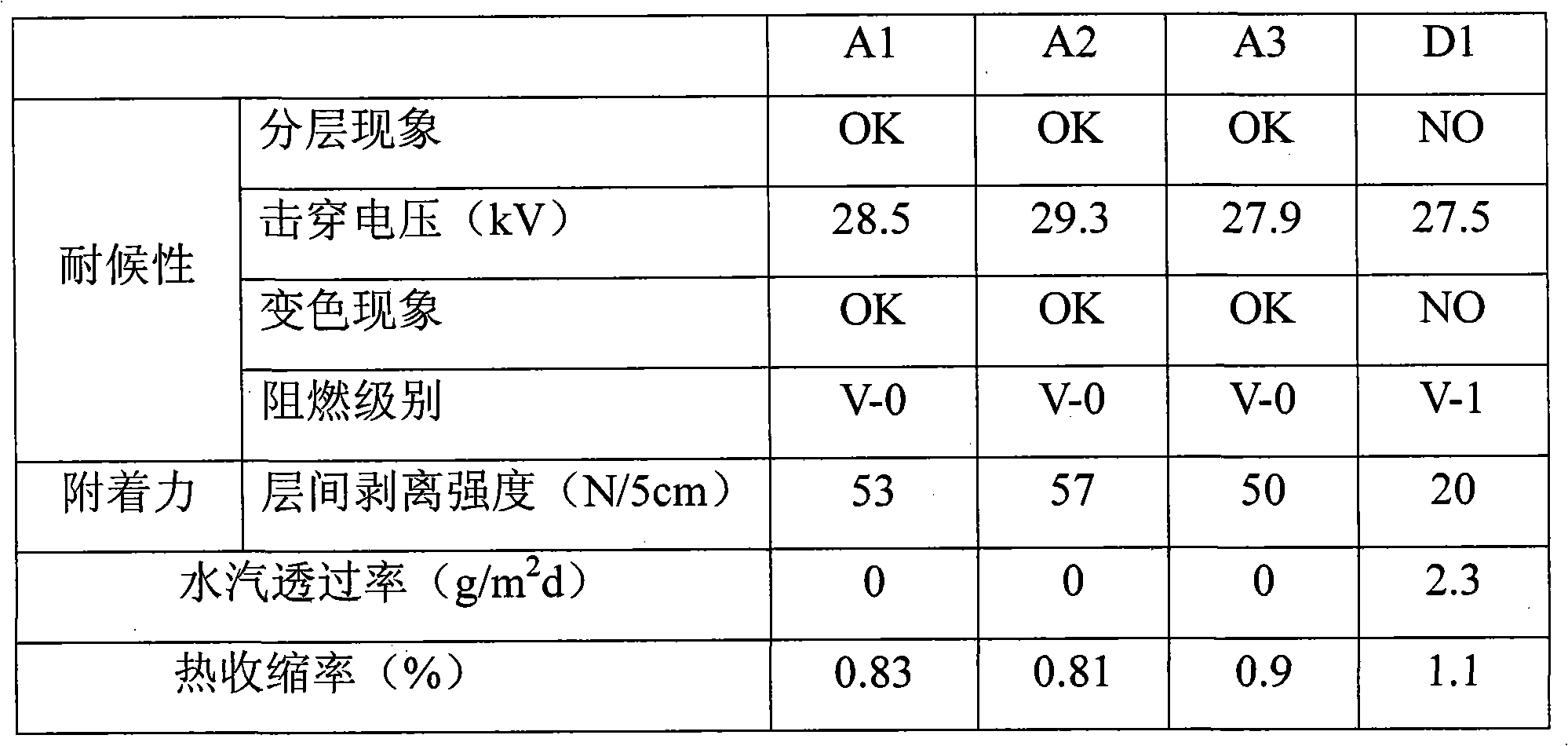

[0031] Take 0.25mm thick aluminum foil as a barrier layer, wipe both sides of the aluminum foil with anhydrous ethanol cotton, and blow dry with a hair dryer. Powder electrostatic spraying equipment (model: HVM2072, manufacturer: Zhengzhou Chaohui Electrostatic Plastic Spraying Equipment Co., Ltd.) is used to spray PPS powder with a thickness of 0.04mm on both sides of the aluminum foil. Then transfer it to an oven and bake at 290°C for 3 minutes, take it out and let it cool naturally, then a PPS weather-resistant layer and a PPS insulating layer can be formed on both sides of the aluminum foil. Through the above steps, the solar cell back sheet of this embodiment is prepared, which is denoted as A1. The solar cell backsheet has figure 1 structure shown.

Embodiment 2

[0033]Take 0.25mm thick aluminum foil as a barrier layer, wipe both sides of the aluminum foil with anhydrous ethanol cotton, and blow dry with a hair dryer. Using co-extrusion compound equipment (model: SJ-LM1250, manufacturer: Changzhou Sanyuan Plastic Machinery Co., Ltd.), using aluminum foil as the middle layer, extruding a 0.05mm thick PPS layer on one surface, and extruding on the other surface 0.05 mm thick PET layer. Then, the PPS layer and the PET layer on the two surfaces of the aluminum foil are hot-compressed and composited with the aluminum foil through the composite roller, so that the PPS weather-resistant layer and the PET insulating layer can be formed on both sides of the aluminum foil. Through the above steps, the solar cell backsheet of this embodiment is prepared, which is denoted as A2.

Embodiment 3

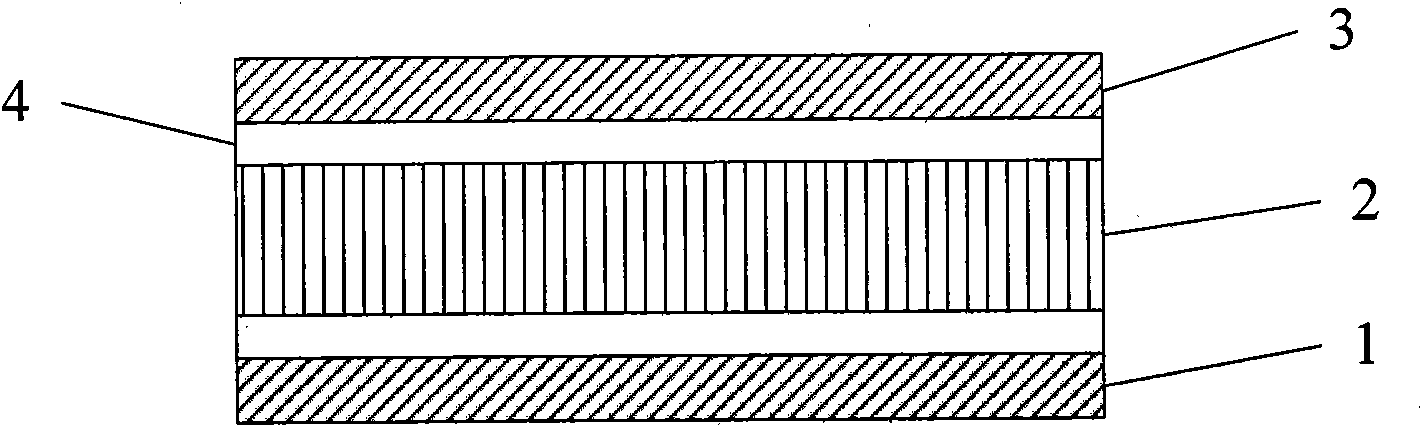

[0035] Take a 0.25mm thick copper-plated film as a barrier layer, wipe both sides of the aluminum foil with anhydrous ethanol cotton, and dry it with a hair dryer. Brush the adhesive EVA with a thickness of 0.01mm on the upper and lower sides of the copper-plated film, and then attach a 0.02mm PPS film to it on one surface, and attach a 0.02mm PC film to it on the other surface, heat Pressure curing, forming a PPS weather-resistant layer and a PC insulating layer on both sides of the copper-plated film. Through the above steps, the solar cell backsheet of this embodiment is prepared, which is denoted as A3. The solar cell backsheet has figure 2 structure shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com