Method for extracting yellow mealworm active proteins by using alkali-enzyme method

An active protein and enzymatic extraction technology, applied in the field of deep processing of Tenebrio molitor protein, can solve the problems of waste of nutrient resources, lack of systematic research, less development and utilization, etc., achieving less investment in equipment, easy product quality control, and short heating time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

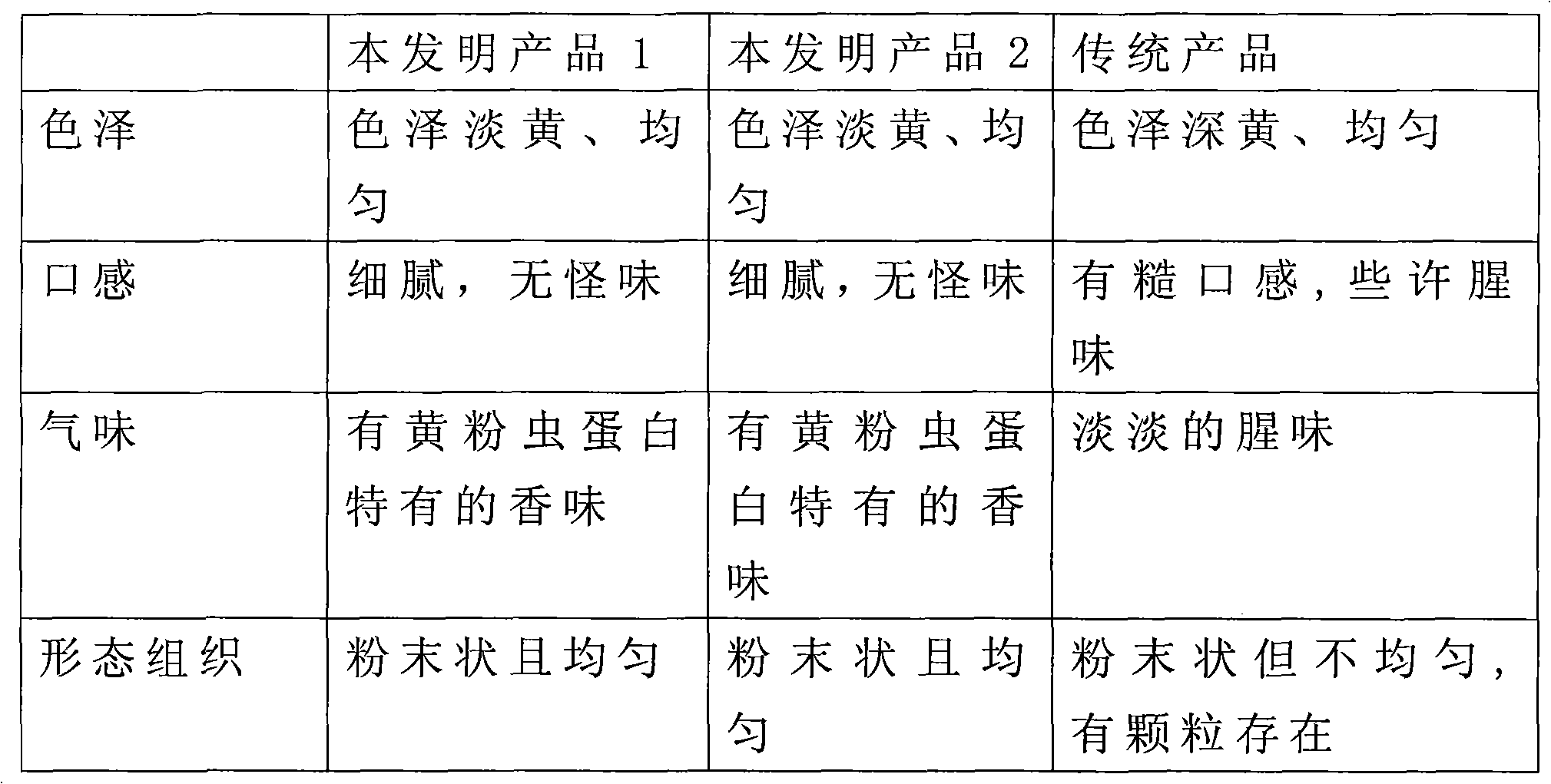

Examples

Embodiment 1

[0014] Take 100 g of fresh Tenebrio molitor larvae and put them into a freeze dryer at -15°C for 10 hours, then dry them continuously for 24 hours under the condition of vacuum degree of 100 Pa and cold trap temperature of -50°C to obtain dry Tenebrio molitor larvae, which are ready for use. Use petroleum ether with a relative density of 0.64 to 0.66 as the leaching solvent, add petroleum ether at the ratio of 1g insect powder to 3ml petroleum ether, and perform secondary extraction. The extraction temperature is 60°C, and the extraction time is 2 hours each time to obtain Tenebrio molitor. Skimmed dry powder. Freeze-dried and degreased Tenebrio molitor dry powder was pre-extracted at 45°C for 1 hour with 0.08mol / L NaOH solution at a ratio of 6ml NaOH solution per gram of insect powder. Then, adjust the pH value to 7.0, at 55°C, add 2.0g of neutral protease and papain, the mass ratio of neutral protease and papain is 1:1, after the extraction time of 120min, heat up to 90°C, k...

Embodiment 2

[0016] Take 100g of fresh Tenebrio molitor larvae and pre-freeze them at -15°C for 15 hours before putting them into a freeze dryer, and then dry them continuously for 24 hours under the conditions of a vacuum of 100Pa and a cold trap temperature of -50°C to obtain dry Tenebrio molitors for later use. Use petroleum ether as the leaching solvent, add 500ml petroleum ether (relative density is 0.64-0.66, analytically pure) for secondary extraction, the leaching temperature is 80°C, and each leaching time is 3h, to obtain the degreasing dry powder of Tenebrio molitor. Freeze-dried and degreased Tenebrio molitor dry powder was pre-extracted at 50°C for 2 hours with 0.10mol / L NaOH solution at a ratio of 8ml NaOH solution per gram of insect powder. Then, adjust the pH value to 7.5, at 60°C, add 3.0g of neutral protease and papain, the mass ratio of neutral protease and papain is 1: 1.5, after the extraction time of 150min, heat up to 90°C, and keep warm for 5 ~10min to inactivate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com