Synthesis method of nano fibrous mordenite

A technology of mordenite and nanofiber, which is applied in the field of catalytic chemistry, can solve the problems of complex preparation process of nano-mordenite, environmental pollution, high synthesis cost, etc., and achieve the effect of improving mass transfer and diffusion, simple synthesis process and good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

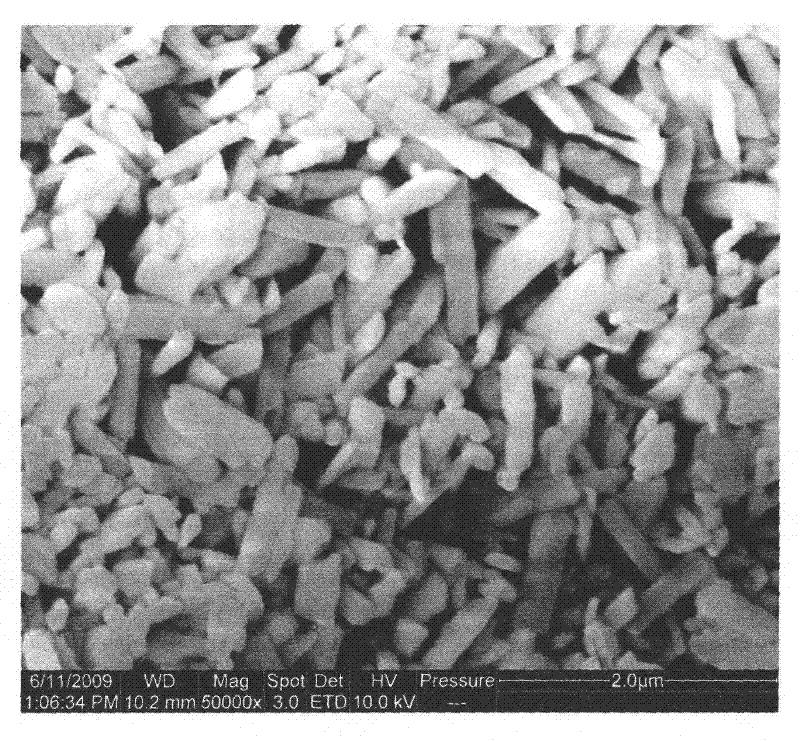

[0020] 18.2g sodium aluminate solution (NaOH 31.2wt.%, Al 2 o 3 16.8wt.%, H 2 O 52.0wt.%, the same below), 14.5g dilute sulfuric acid solution (0.3g H 2 SO 4 / ml, the same below) and 99.7g of deionized water were added to the reaction kettle and mixed evenly, then 19.6g of solid silica gel (SiO 2 92.0wt.%, H 2 O 8.0wt.%, hereinafter the same), and finally add 0.2g of mordenite as a seed crystal. The molar ratio of the reaction mixture is SiO 2 / Al 2 o 3 =10, Na 2 O / Al 2 o 3 = 1.0, H 2 O / Al 2 o 3 =225, the seed crystal addition amount is 1.0% of the total mass of the raw material silicon aluminum oxide. The reaction vessel was sealed and placed in a synthesis oven for dynamic crystallization at 164°C for 60 hours. After the reaction, the reactor was cooled, the solid and the mother liquor were centrifuged, the solid was washed with deionized water to pH 8-9, and dried in air at 100° C. for 8 hours to obtain a molecular sieve powder. The final product is pure mo...

Embodiment 2

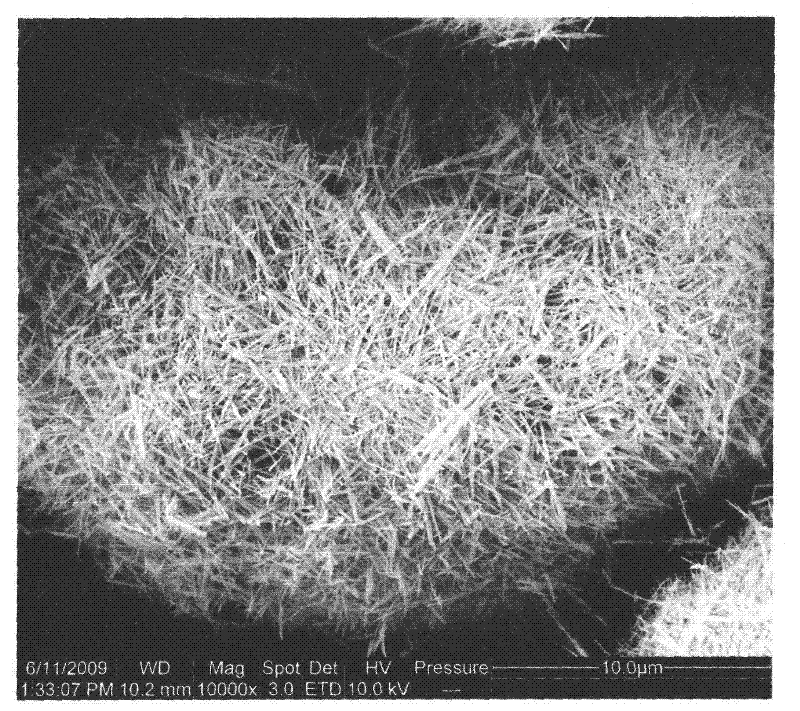

[0022] The water content in embodiment 1 is increased by 50%, that is, the molar ratio of the reaction mixture is SiO 2 / Al 2 o 3 =10, Na 2 O / Al 2 o 3 = 1.0, H 2 O / Al 2 o 3 =337.5, the crystallization time was extended to 96 hours, and other conditions remained unchanged. The final product is pure mordenite as tested by XRD, and the XRD spectrum is shown in figure 1 C; see its SEM photo Figure 4 , TEM photo see Figure 5 , the product is in the form of nanofibers with a grain length of 3-7 microns and a width of about 40 nanometers.

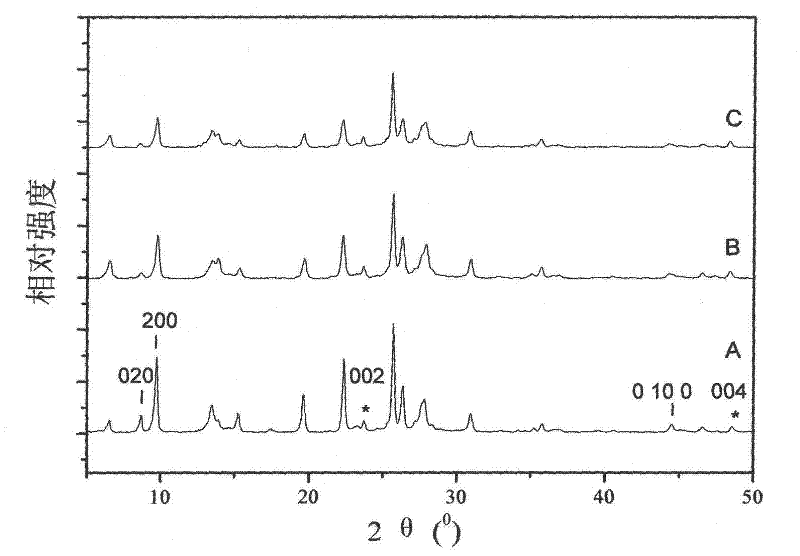

[0023] Compared figure 1 A, B, and C can be seen (wherein A is the XRD spectrum of the industrially produced mordenite sample provided by Fushun Petrochemical Company): although the XRD peak positions of the three samples are the same, and they are all pure mordenite, there are obvious differences in the peak intensity and width of the three samples. difference, the peak intensity order corresponding to the crystal planes [020], [200...

Embodiment 3

[0025]Keep the raw material ratio of Example 1, change sulfuric acid into hydrochloric acid (0.2g HCl / ml), the amount of seed crystals is changed into 2.1g (add-on is 10% of the raw material silicon-aluminum oxide gross mass), and crystallization temperature is changed into At 180°C, the crystallization time was shortened to 30 hours, and other conditions remained unchanged. The final product was tested as pure mordenite by XRD, and its SEM photo is shown in Image 6 , the product is a divergent nanofiber with a grain length of 1-2 microns and a width of about 30 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com