Preparation method of tin dioxide self-assembly nanostructure microsphere

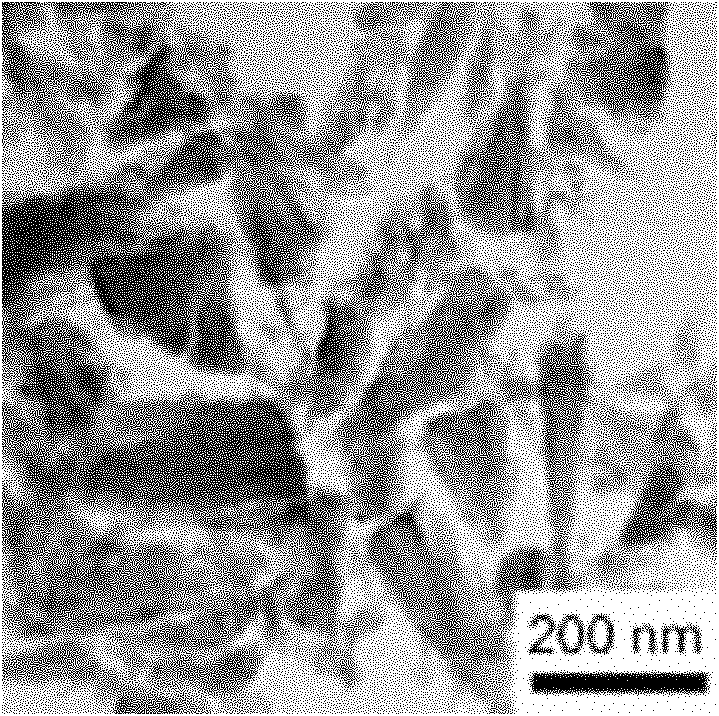

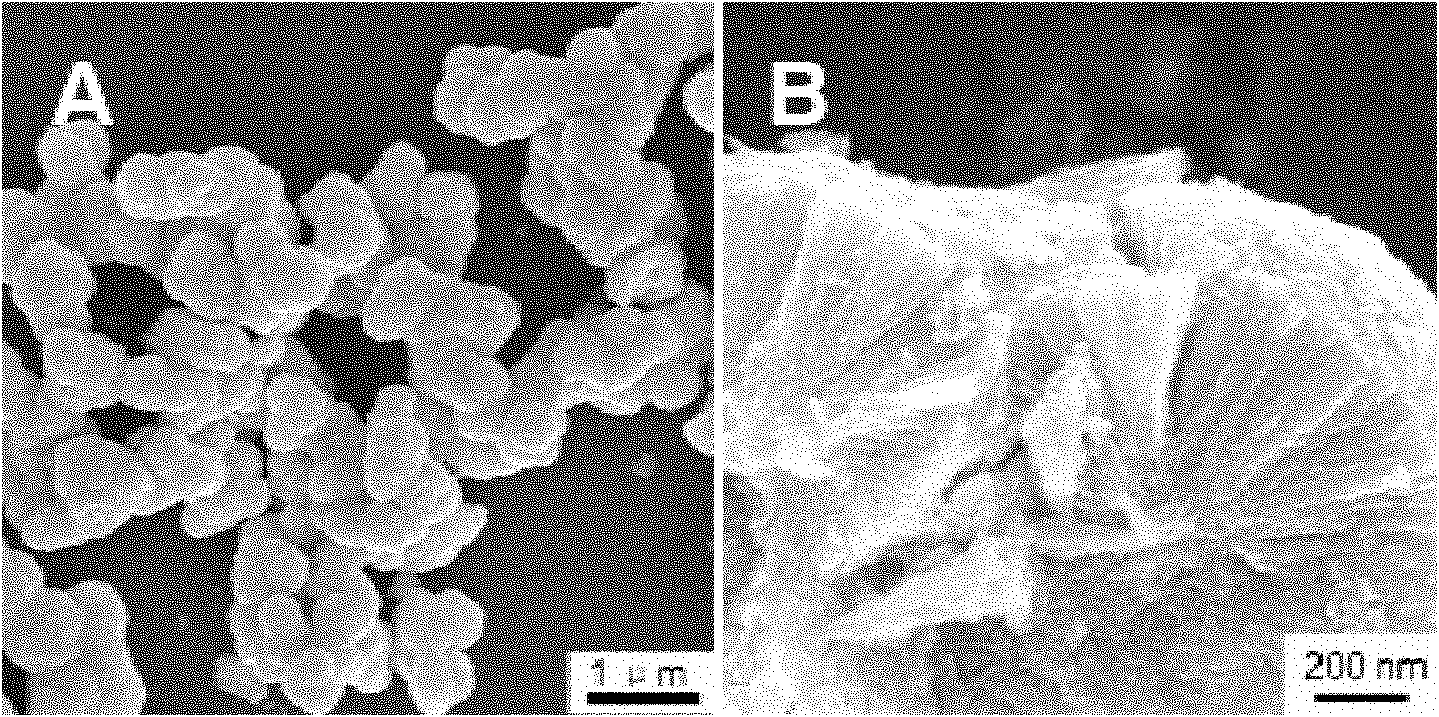

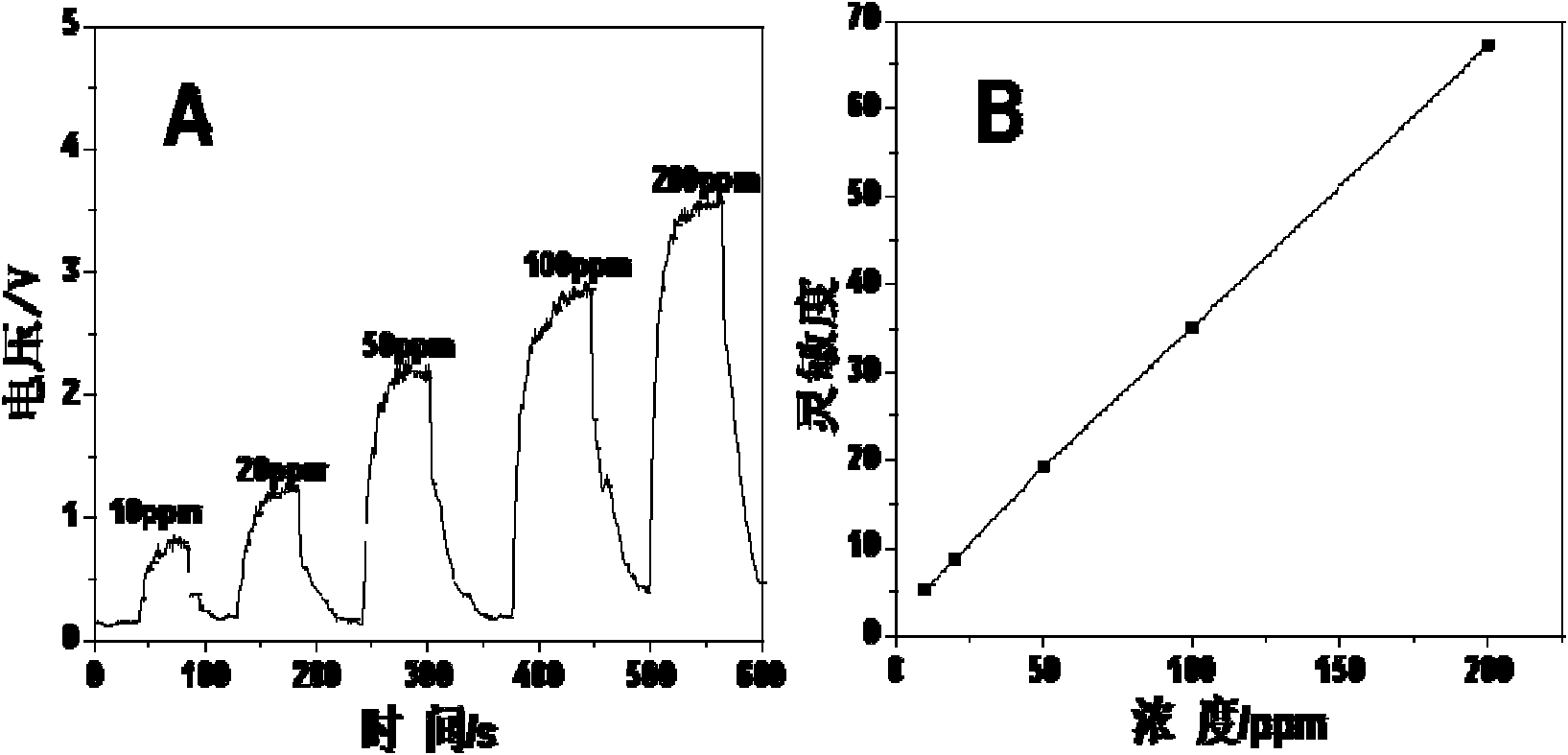

A nanostructure and tin dioxide technology, applied in the field of preparation of nanocone self-assembled spheres, to achieve uniform structure, low cost, and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) First, weigh 1 mmol of sodium stannate trihydrate and 2 mmol of cetyltrimethylammonium bromide into a mixed solvent of 5 ml of ethanol and 17.5 ml of water.

[0042] (2) Add 5ml of ethanolamine solution into the mixed solution of (1), and stir with a glass rod for 5 minutes until the solution is evenly mixed. (3) the solution is transferred to a volume of 45ml and has a polytetrafluoroethylene-lined stainless steel autoclave, the filling degree is 61%, put into an oven and carry out hydrothermal reaction, the temperature is 180 ℃, and the reaction time is 24 hours. After cooling down to room temperature, the bottom product was washed by centrifugation.

[0043] (4) Add dehydrated ethanol to the bottom product and centrifuge at 4500r / min at a rotating speed for 5min, remove the supernatant and then add deionized water to centrifuge at 4500r / min for 5min, remove the supernatant and then add absolute ethanol at a rotating speed of 4500r / min Centrifuge for 5 min at 1 m...

Embodiment 2

[0048] (1) First, weigh 1 mmol of sodium stannate trihydrate and 2 mmol of cetyltrimethylammonium bromide into a mixed solvent of 15 ml of ethanol and 7.5 ml of water.

[0049] (2) Add 5ml of ethanolamine solution into the mixed solution of (1), and stir with a glass rod for 5 minutes until the solution is evenly mixed.

[0050] (3) the solution is transferred to a volume of 45ml and has a polytetrafluoroethylene-lined stainless steel autoclave, the filling degree is 61%, put into an oven and carry out hydrothermal reaction, the temperature is 180 ℃, and the reaction time is 24 hours. After cooling down to room temperature, the bottom product was washed by centrifugation.

[0051] (4) Add dehydrated ethanol to the bottom product and centrifuge at 4500r / min at a rotating speed for 5min, remove the supernatant and then add deionized water to centrifuge at 4500r / min for 5min, remove the supernatant and then add absolute ethanol at a rotating speed of 4500r / min Centrifuge for 5 m...

Embodiment 3

[0056] (1) First, weigh 1 mmol of sodium stannate trihydrate and 2 mmol of cetyltrimethylammonium bromide into a mixed solvent of 17 ml of ethanol and 5.5 ml of water.

[0057] (2) Add 5ml of ethanolamine solution into the mixed solution of (1), and stir with a glass rod for 5 minutes until the solution is evenly mixed.

[0058] (3) the solution is transferred to a volume of 45ml and has a polytetrafluoroethylene-lined stainless steel autoclave, the filling degree is 61%, put into an oven and carry out hydrothermal reaction, the temperature is 180 ℃, and the reaction time is 24 hours. After cooling down to room temperature, the bottom product was washed by centrifugation.

[0059] (4) Add dehydrated ethanol to the bottom product and centrifuge at 4500r / min at a rotating speed for 5min, remove the supernatant and then add deionized water to centrifuge at 4500r / min for 5min, remove the supernatant and then add absolute ethanol at a rotating speed of 4500r / min Centrifuge for 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com