Preparation method of dolomite tailing bricks

A technology for dolomite and tailings, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. The effect of high mold integrity rate, high molding compactness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Raw material preparation:

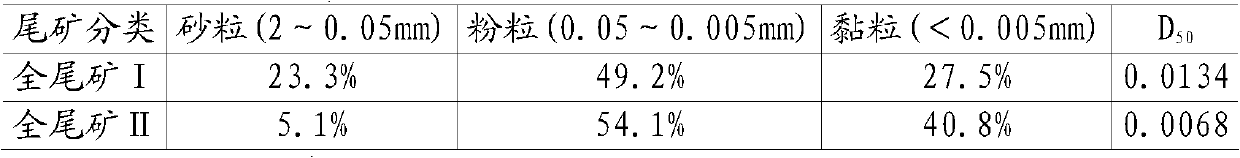

[0025] Pre-treatment of dolomite tailings: sieve the dolomite tailings slurry to remove plant roots and large rocks, then air-dry naturally to obtain dolomite tailings with a water content of <1%.

[0026] Raw materials: 9 parts by weight of PCSB curing agent, 81 parts by weight of dolomite tailings, and 10 parts by weight of water.

[0027] Method: Stir PCSB curing agent and dolomite tailings for 50-70 seconds to obtain a dry mixture of curing agent and dolomite tailings, and then mix and grind the mixed dry material for 50-70 seconds to make the mud particle size in the mixture <0.5mm, Then carry out two-stage forced mixing and milling of the mixed dry material for 170-200 seconds, and spray water into the mixed material in the form of spray at the same time of mixing and milling. When spraying, the particle size of the droplets is <0.5mm, and the spray speed is 0.8-1.6kg / s , Rolling and mixing the uniform mixture into the mold in a vibrat...

Embodiment 2

[0029] Raw material preparation:

[0030] Pre-treatment of dolomite tailings: sieve the dolomite tailings slurry to remove plant roots and large rocks, then air dry naturally to obtain dolomite tailings with a water content of 4.5%.

[0031] Raw materials: 10.8 parts by weight of curing agent, 82.93 parts by weight of dolomite tailings, and 6.27 parts by weight of water.

[0032] Method: first mix and grind the dolomite tailings for 50-70 seconds, then add a curing agent and mix and grind for 50-70 seconds, so that the particle size of the mud particles in the mixture is 2 , the genuine products are sent to the maintenance site through the conveyor belt or forklift dispersion system to obtain dolomite tailings bricks, and the defective products or leakage materials are sent back to the secondary forced mixing and grinding. The milling can use a milling machine.

Embodiment 3

[0034] Raw material preparation:

[0035] Pre-treatment of dolomite tailings: sieve the dolomite tailings slurry to remove plant roots and large rocks, then air dry naturally to obtain dolomite tailings with a water content of 2.5%.

[0036] Raw materials: 9.9 parts by weight of cement-based curing agent, 82.15 parts by weight of dolomite tailings, and 7.95 parts by weight of water.

[0037] Method: first use the mixing and grinding device to mix and grind the mixture of dolomite tailings and curing agent for 100 to 130 seconds, so that the particle size of the mud particles in the mixture is 2 , the genuine products are sent to the maintenance site through the conveyor belt or forklift dispersion system to obtain dolomite tailings bricks, and the defective products or leakage materials are sent back to the second-level forced wheel grinding.

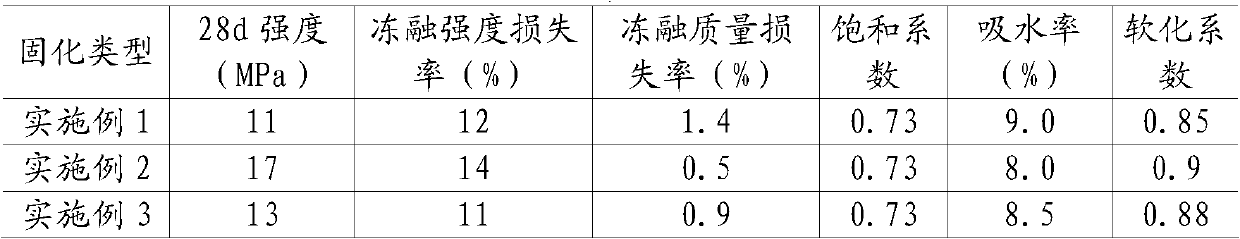

[0038] The dolomite tailings made in the above-mentioned embodiments 1-3 are as the tailings test piece and the tailings standard brick ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com