Preparation method of nano magnetic core-shell catalyst for degrading dye wastewater

A core-shell catalyst, nano-magnetic technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve waste, difficult to recycle nano-catalysts, nano-catalysts Efficiency is not high enough to achieve the effect of easy recycling and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation of embodiment 1 nanometer magnetic core-shell catalyst

[0017] The preparation process of the catalyst is carried out in two steps. The first step is to prepare the pure phase strong magnetic core Fe 3 o 4 ; The second step: the preparation of nano-magnetic core-shell catalyst: the newly prepared concentration of 0.2mol / L FeSO 4 with Fe 3 o 4 Suspension mixing, control of Fe 3 o 4 and FeSO 4 The amount ratio of the substance is 1:5, add concentrated alkali (NaOH solution) to the pH of the system to 7, and then add KMnO with a certain volume concentration of 0.2mol / L at a slower rate of addition 4 solution, control FeSO 4 and KMnO 4 The amount ratio of the substance is 1:1.5, and the pH of the system is controlled to be 7 constant during the dropping process. After the dropping is completed, it is reacted in a water bath at 50-80°C for 4 hours. After the end, it is separated by suction filtration and washed 4 times with deionized water. Dry over...

Embodiment 2

[0018] The structure and component analysis of embodiment 2 nanometer magnetic core-shell catalyst

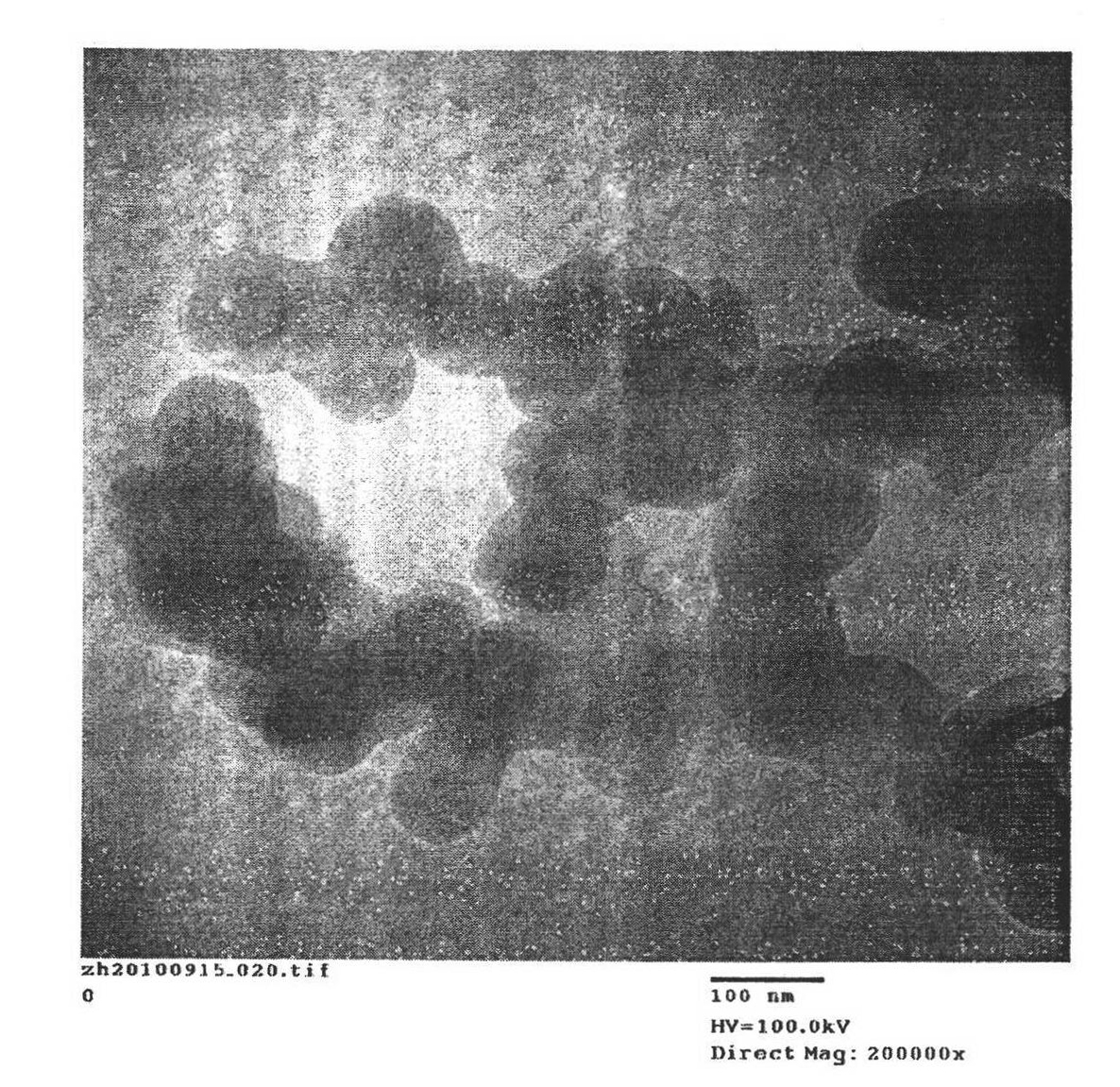

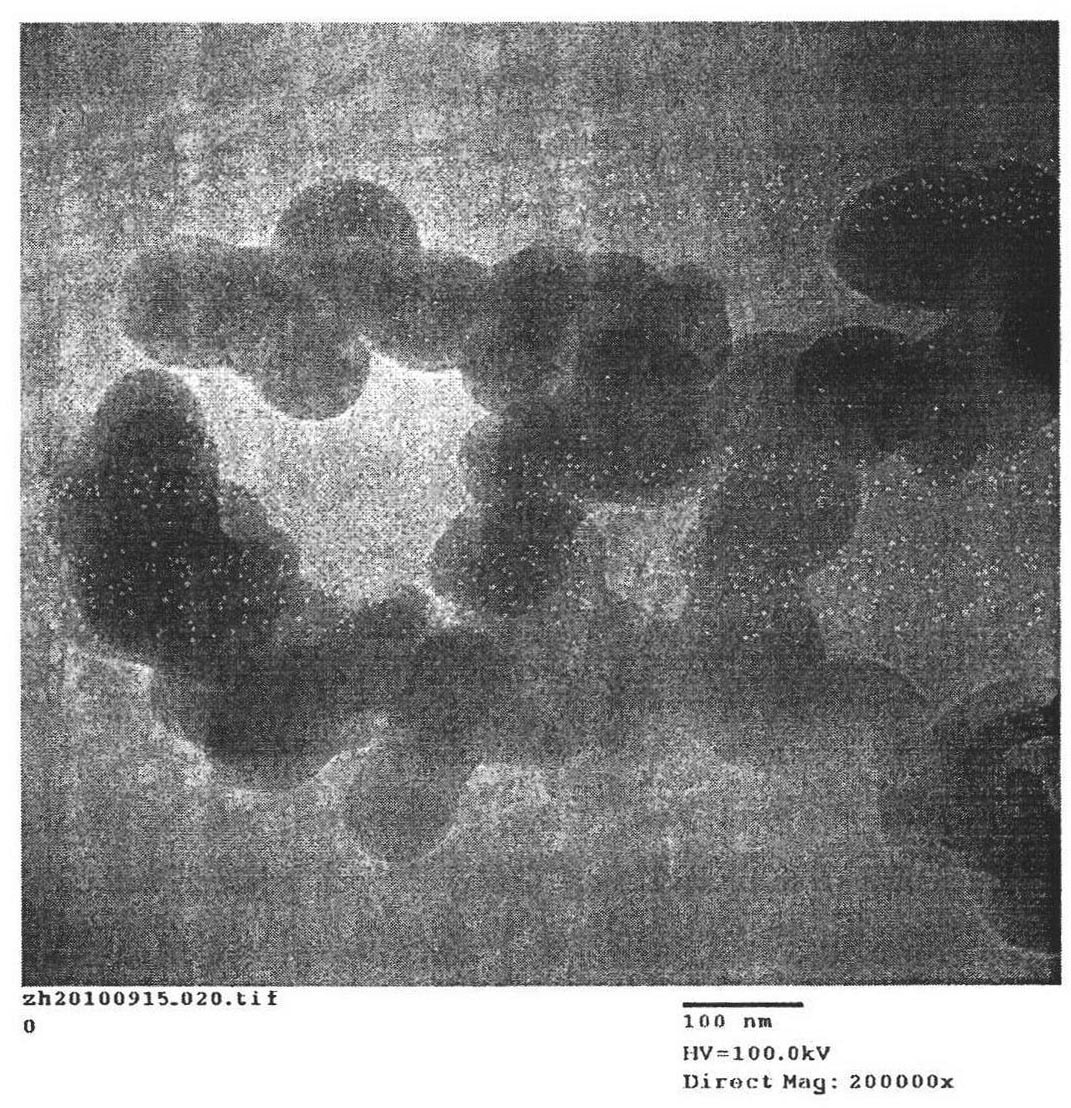

[0019] The microscopic morphology of the obtained samples was observed with a high-power transmission electron microscope (TEM). The core-shell structure can be clearly seen from the transmission photographs. The inner core is pure phase Fe 3 o 4 , the particle size is relatively uniform, the size is between 30 and 60 nanometers, and the thickness of the shell is between 10 and 20 nanometers. The element content of the material is analyzed by electron microscope energy spectrum. It can be seen that the material mainly contains three elements: iron, oxygen and manganese. Different concentrations of KMnO 4 The molar ratio of iron and manganese elements in the material prepared as the reactant is (15:1)-(3:1).

Embodiment 3

[0020] Catalytic oxidation activity of embodiment 3 nanometer magnetic core-shell catalyst

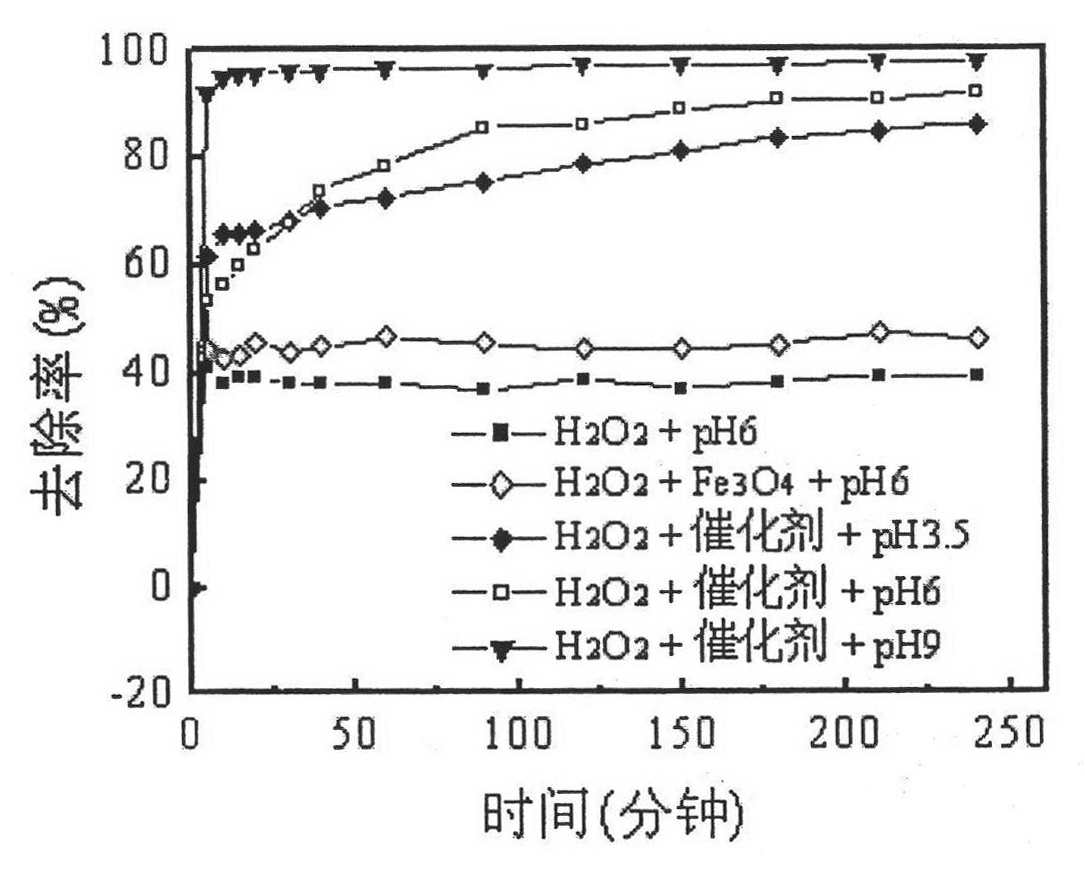

[0021] Take methylene blue as the target pollutant to evaluate the catalytic oxidation activity of the core-shell structure iron-manganese composite oxide nanomaterial of the present invention, the results are as follows figure 2 shown.

[0022] In the case of no catalyst, the removal rate of pollutants is only about 6%, and the corresponding Fe 3 o 4 It also did not show better activity. However, the core-shell structure catalytic material prepared by the present invention has a higher catalytic effect on organic pollutants under different pH conditions. 98%. The above results show that the material is a heterogeneous catalyst with excellent performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com