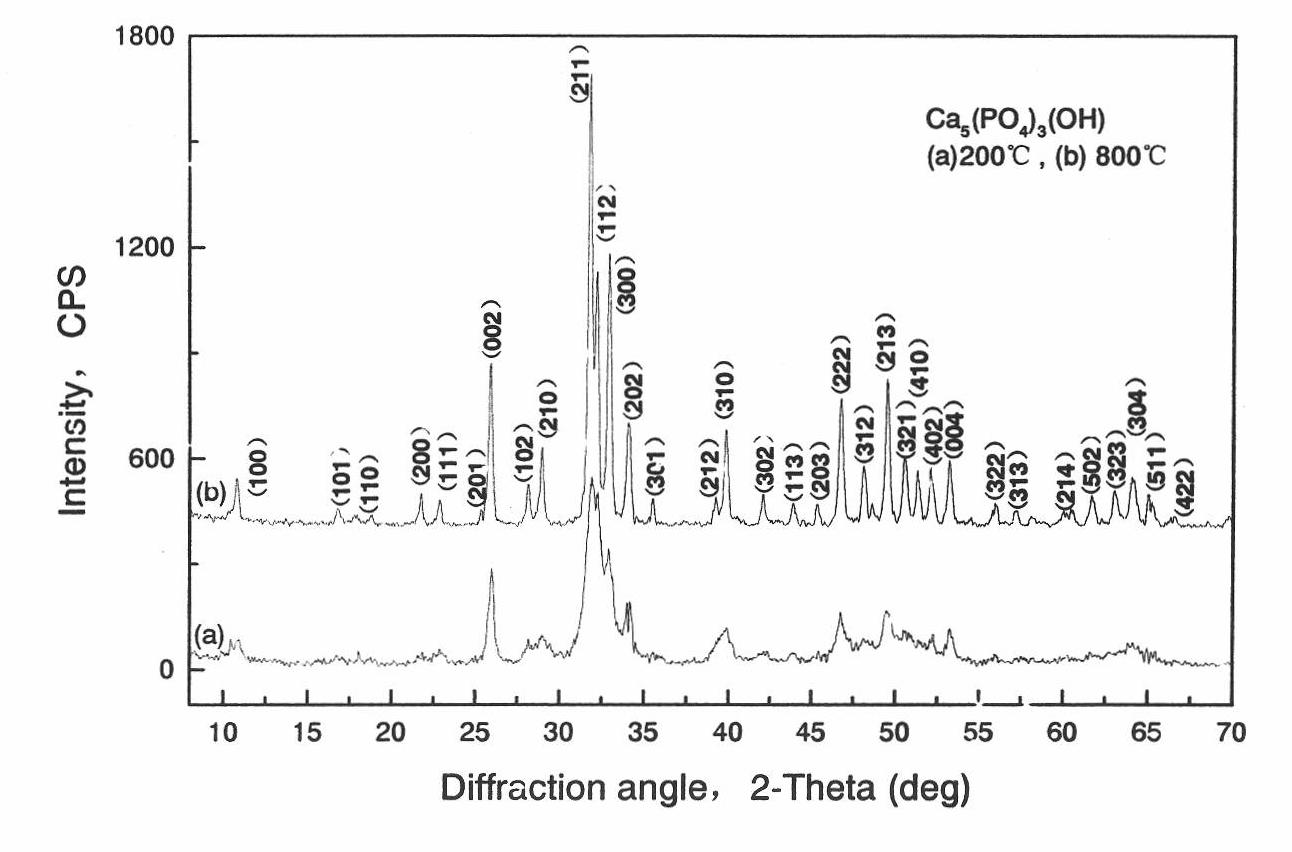

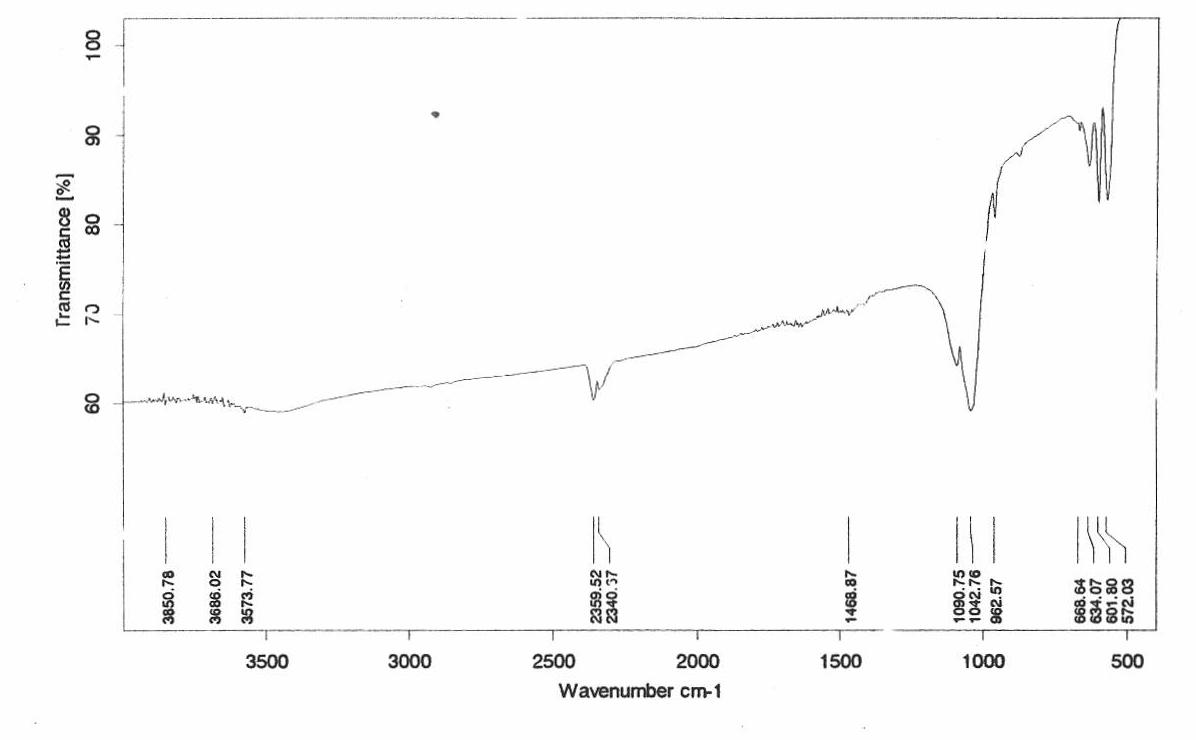

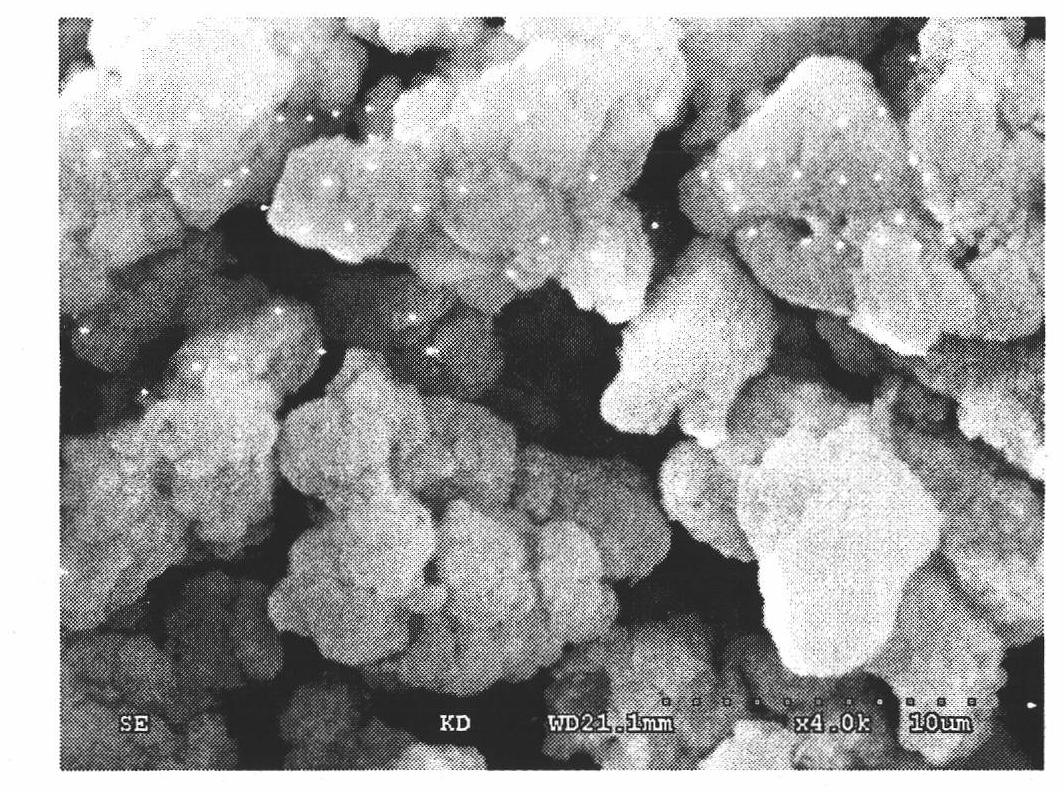

Method for synthesizing high-purity hydroxyapatite (HA) from eggshells under hydrothermal condition

A technology of hydrothermal synthesis of hydroxyapatite, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as lack of research, achieve the effects of wide sources, reduce preparation costs, and increase added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Collect part of the egg shells, wash with tap water to remove the soil and adhering impurities on the egg shells, boil hot water for a period of time, and remove the inner film after drying. The dried eggshells are broken into small pieces, placed in a crucible, and calcined in a box-type resistance furnace. The first step is to raise the temperature to 450°C, keep it for 2 hours, then raise the temperature to 900°C, keep it for 4 hours, and cool down to room temperature with the furnace. Grind the calcined white eggshell into powder with a mortar, pass through a 120-mesh sieve, collect 10 g of calcined eggshell powder (composition is CaO), weigh diammonium hydrogen phosphate ((NH 4 ) 2 HPO 3 , Shantou Xilong Chemical Co., Ltd.) 18g of (NH 4 ) 2 HPO 3 Solution, heated to 90°C in a constant temperature water bath and kept warm, under the condition of strong stirring, eggshell powder was gradually added to (NH 4 ) 2 HPO 3 in solution. Stir and react at a constant ...

Embodiment 2

[0022] Collect part of the egg shells, wash with tap water to remove the soil and adhering impurities on the egg shells, boil hot water for a period of time, and remove the inner film after drying. The dried eggshells are broken into fine pieces, placed in a crucible, and calcined in a box-type resistance furnace. The first step is to raise the temperature to 450°C, keep it for 2 hours, then raise the temperature to 900°C, keep it for 4 hours, and cool down to room temperature with the furnace. Grind the calcined white eggshell into powder with a mortar and mortar, pass through a 120-mesh sieve, collect 10 g of calcined eggshell powder (composition is CaO), weigh it as analytically pure diammonium hydrogen phosphate ((NH 4 ) 2 HPO 3 , Shantou Xilong Chemical Co., Ltd.) 18g of (NH 4 ) 2 HPO 3 Solution, heated to 90°C in a constant temperature water bath and kept warm, under the condition of strong stirring, eggshell powder was gradually added to (NH 4 ) 2 HPO 3 in soluti...

Embodiment 3

[0026] Collect part of the egg shells, wash with tap water to remove the soil and adhering impurities on the egg shells, boil hot water for a period of time, and remove the inner film after drying. The dried eggshells are broken into small pieces, placed in a crucible, and calcined in a box-type resistance furnace. The first step is to raise the temperature to 450°C, keep it for 2 hours, then raise the temperature to 900°C, keep it for 4 hours, and cool down to room temperature with the furnace. Grind the calcined white eggshell into powder with a mortar and mortar, pass through a 120-mesh sieve, collect 10 g of calcined eggshell powder (composition is CaO), weigh it as analytically pure diammonium hydrogen phosphate ((NH 4 ) 2 HPO 3 , Shantou Xilong Chemical Co., Ltd.) 18g of (NH 4 ) 2 HPO 3 Solution, heated to 90°C in a constant temperature water bath and kept warm, under the condition of strong stirring, eggshell powder was gradually added to (NH 4 ) 2 HPO 3 in solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com