Polyolefin/vegetable fiber composite material and preparation method thereof

A plant fiber and composite material technology, which is applied in the field of polyolefin modification technology and the field of comprehensive utilization of plant fibers, can solve the problems of increasing the production cost of composite materials, reducing the tensile strength and modulus of composite materials, etc., and achieves low cost and improved Interfacial interaction, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Ⅰ The preparation method of polyolefin / plant fiber composite material:

[0028] (1) Screening and drying of plant fibers. In Examples 1 to 8, after the plant fibers are sieved through a 60-mesh sieve, the moisture content is lower than 2% by drying treatment, and then set aside;

[0029] (2) Preliminary mixing of raw materials. Mix the dried plant fibers and processing aids in the high-speed mixer for 5 minutes; turn on the high-speed mixer, add the polyolefin resin and functional modified masterbatch with the formula, and mix again at high speed for 3 minutes;

[0030] (3) Extrusion granulation of composite materials. In the twin-screw extruder, the primary mixed material is extruded and granulated. The temperature of the extruder is set at 160-200°C, and the screw speed of the extruder is 80rpm-120rpm. After the extruded material passes through the die, it enters the profile Styling equipment, cooling, cutting, stacking, that is, polyolefin / plant fiber composites w...

Embodiment 1~8

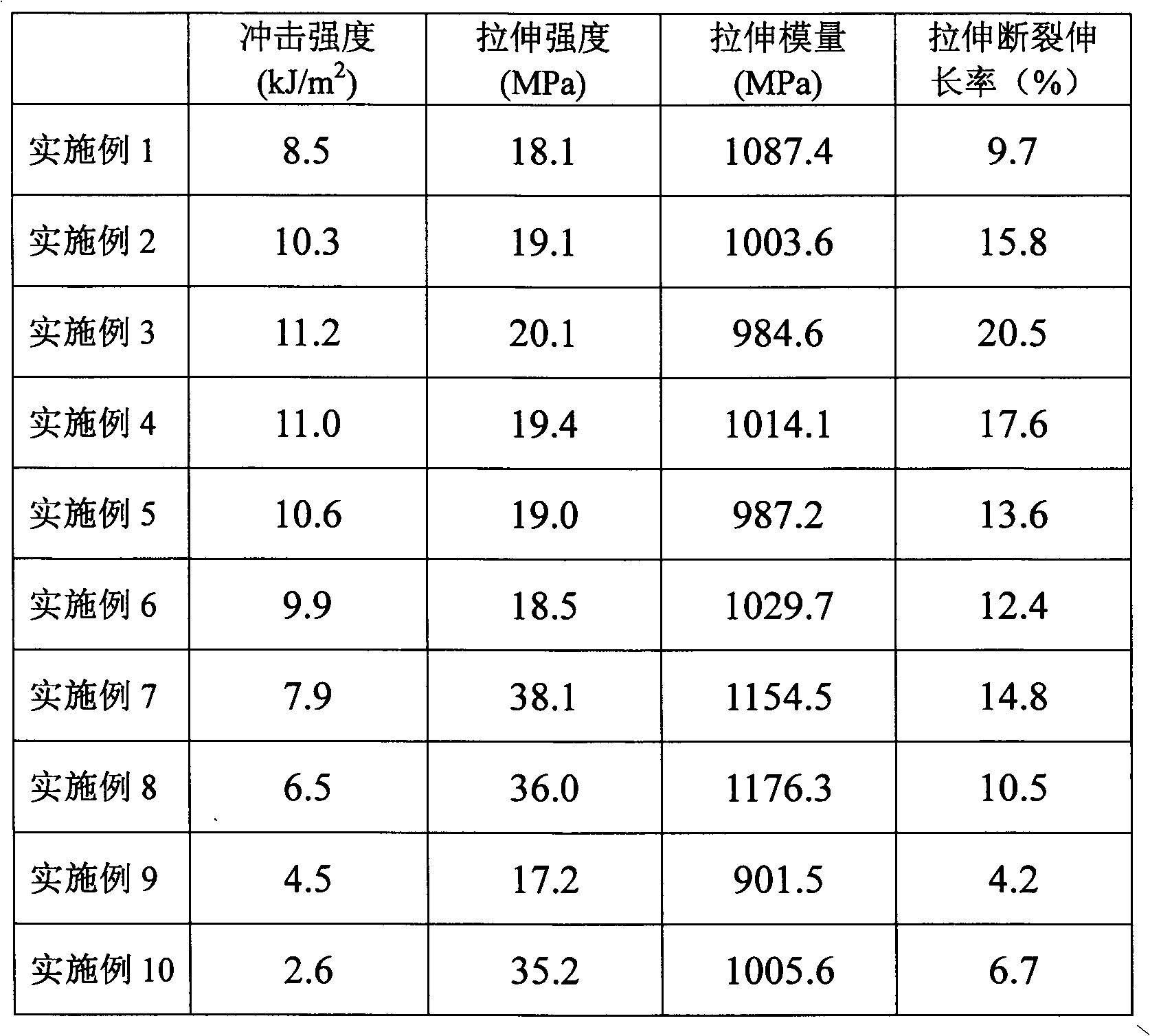

[0033] Below provide 10 embodiments of specific formula composition and component content, the preparation method of the polyolefin / plant fiber composite material of indication is carried out by the step that 1 provides. Example 9 and Example 10 for comparison do not contain the functional modified masterbatch provided by the present invention.

Embodiment 1

[0034] Embodiment 1: by weight: 30 parts of polyethylene resin, 70 parts of rice straw powder; functional modified masterbatch is 10% of the total weight of polyethylene resin and straw powder; processing aid is the total weight of polyethylene resin and straw powder 4% by weight; in the functional modified masterbatch, 25% of oxidized polyethylene, 20% of talcum powder and 55% of nanometer calcium carbonate are contained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com