Purification method of converter gas

A converter gas and gas technology, applied in chemical instruments and methods, separation methods, manufacturing converters, etc., can solve the problems that cannot meet the requirements of chemical production, contain a large amount of impurities, etc., meet the requirements, remove high precision, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

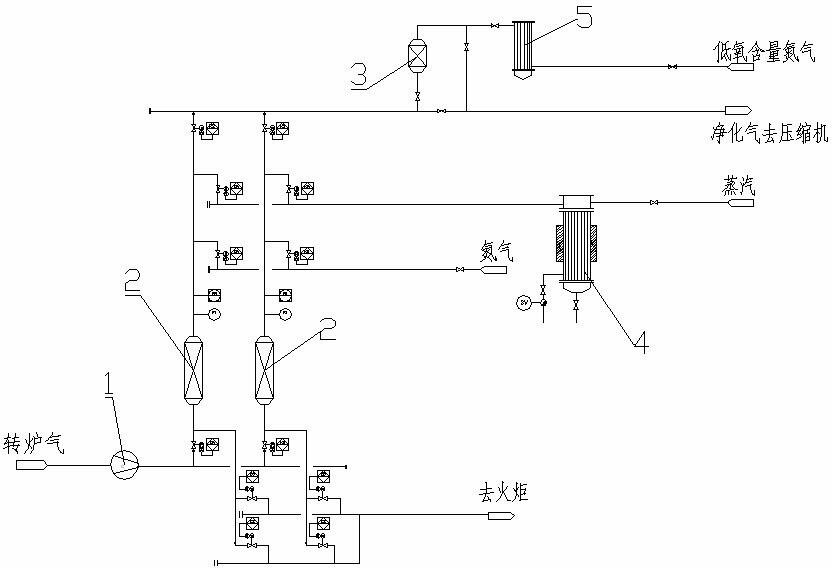

[0023] Embodiment 1: as figure 1 Shown, a kind of purification method of converter gas comprises the following steps:

[0024] Converter gas 500Nm 3 / h After being washed with water to remove dust and cool down, and then pressurized to 1.5MPa by a blower, it is sent to the second tower pressure swing temperature swing adsorption device. The variable pressure and temperature device consists of two adsorption beds to form a continuous operation system, each of which must undergo the following steps in a cycle:

[0025] (1) Adsorption

[0026] The converter gas is fed into the adsorption bed from bottom to top for adsorption, and the purified gas is discharged from the top of the bed. When the leading edge of the adsorption zone moves upwards to a certain position in the bed, after the sulfur, phosphorus, arsenic and their compounds reach the specified concentration in the purified gas, the converter gas enters and the adsorption is stopped. At this time, the raw material gas ...

Embodiment 2

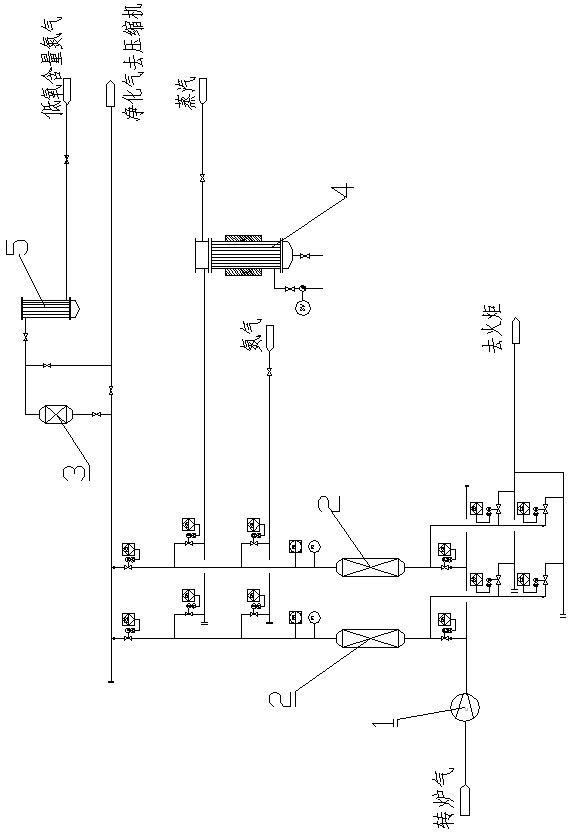

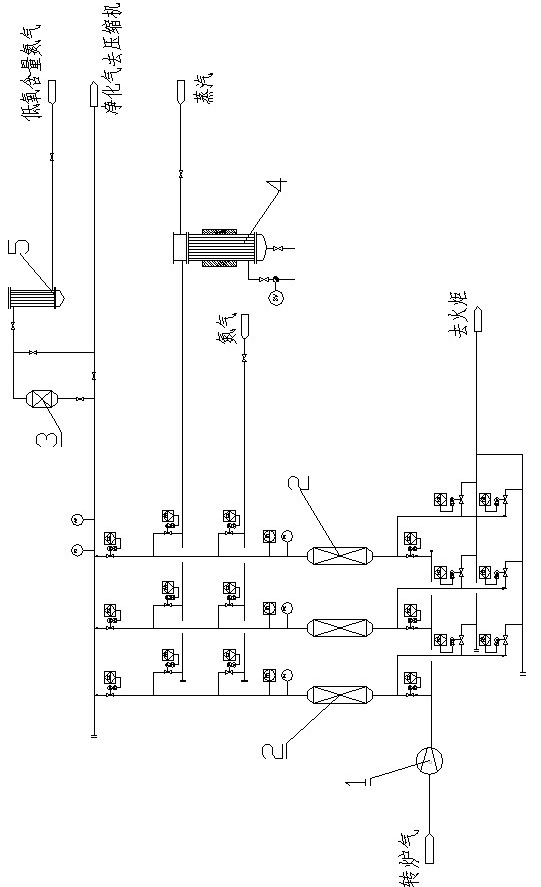

[0039] Embodiment 2: as figure 2 Shown, a kind of purification method of converter gas comprises the following steps:

[0040] 3000Nm 3 The converter gas per hour is washed and dedusted in two stages, cooled, and then pressurized to 0.05MPa by a blower before being sent to a three-tower pressure-swing temperature-swing adsorption device.

[0041] The three-tower variable pressure and temperature device consists of three adsorption beds to form a continuous operation system, each of which must undergo the following steps in a cycle:

[0042] (1) Adsorption

[0043] The converter gas is fed into the adsorption bed from bottom to top for adsorption, and the purified gas is discharged from the top of the bed. When the leading edge of the adsorption zone moves upwards to a certain position in the bed, after the sulfur, phosphorus, arsenic and their compounds reach the specified concentration in the purified gas, the converter gas enters and the adsorption is stopped. At this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com