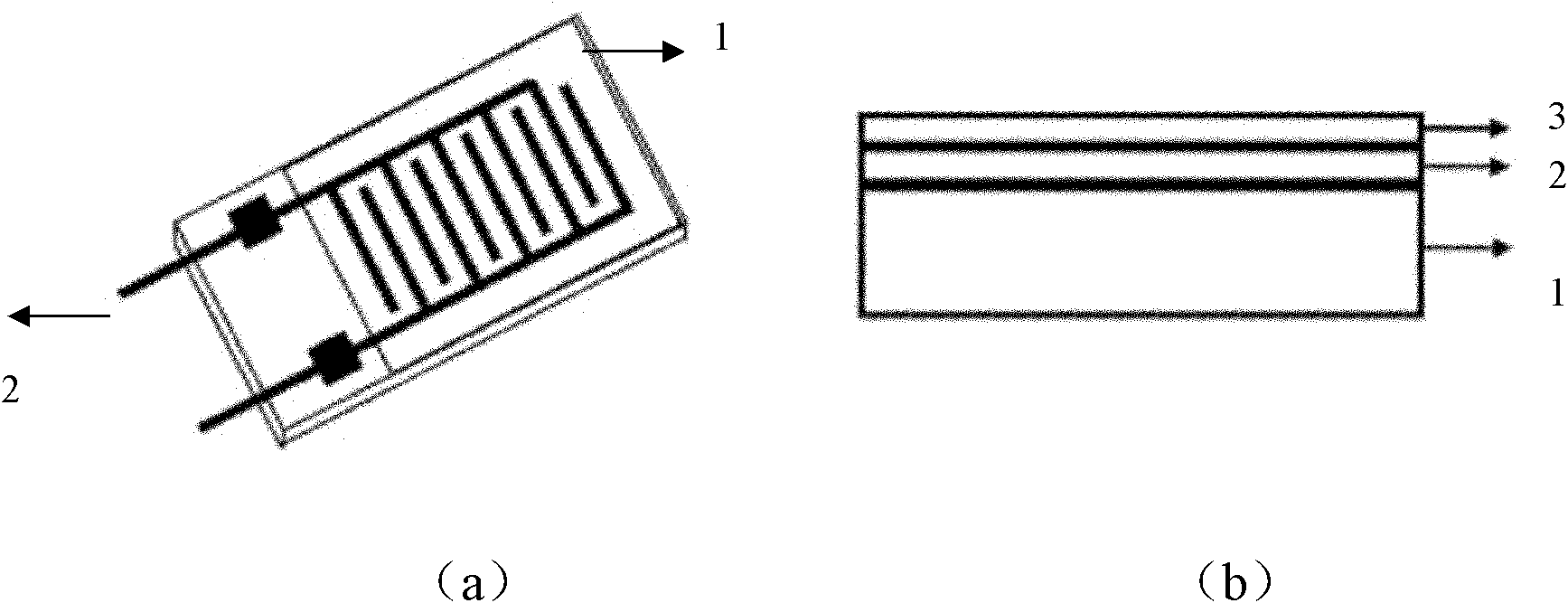

Preparation method for fast-response and wide-range ceramic-based nano-fiber humidity sensor

A humidity sensor and nanofiber technology, applied in nanotechnology, material resistance, etc., can solve the problem of long response recovery time, achieve high response recovery speed, increase the rate of radial transmission, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

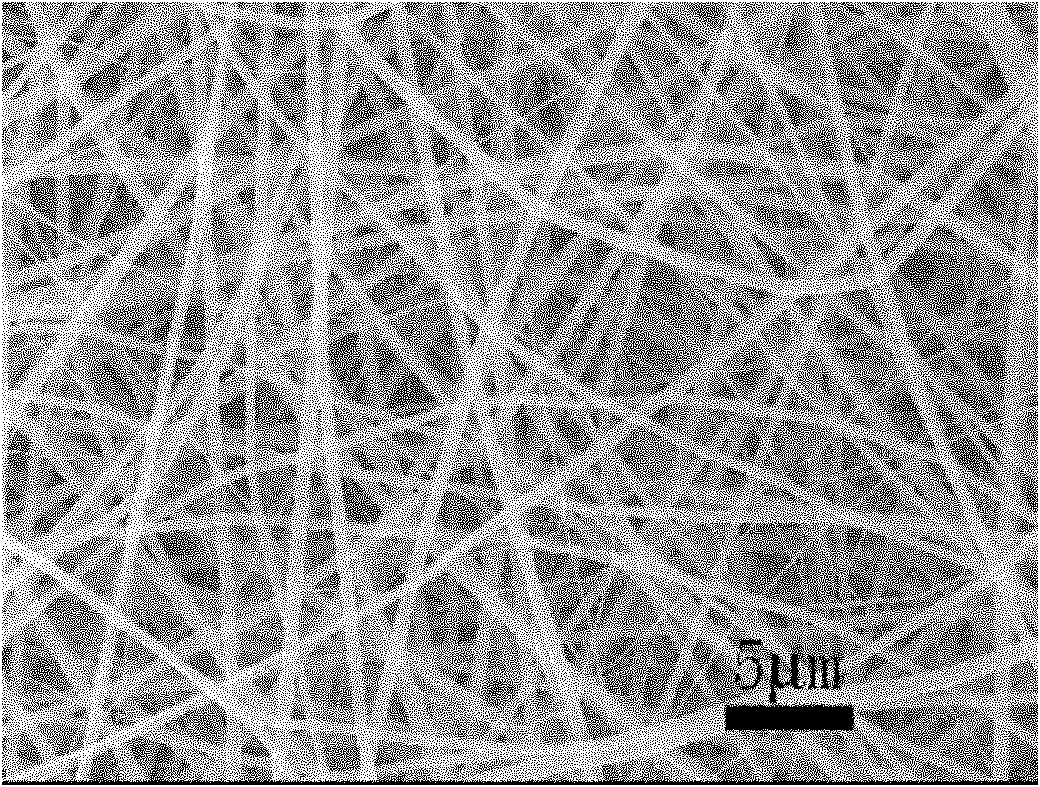

Embodiment 1

[0053] In a 30ml Erlenmeyer flask, 1.0g of polyvinylpyrrolidone was added into 3ml of ethanol, and magnetically stirred at 25°C for 4 hours to completely dissolve it.

[0054] Another 30ml Erlenmeyer flask was taken, and 2ml of ethanol, 2ml of glacial acetic acid and 1g of tetrabutyl titanate were added in sequence, and magnetically stirred at 25°C for 20 minutes to make it evenly mixed.

[0055] Take another 30ml Erlenmeyer flask, add 0.75g of barium acetate into 1ml of deionized water, and stir until completely dissolved. Then add the dissolved barium solution into the mixed ester solution, and magnetically stir for 20 minutes at 25° C. to make the solution evenly mixed. Finally, add this mixed solution into the polymer solution, and continue magnetic stirring at 25°C for 20 minutes to make the solution evenly mixed;

[0056] The mixed solution is put into a plastic spinneret, the inner diameter of the plastic spinneret is 1mm, the copper wire is used as the anode, the alum...

Embodiment 2

[0058] In a 30ml Erlenmeyer flask, 1.0g of polyvinylpyrrolidone was added into 3ml of ethanol, and magnetically stirred at 25°C for 4 hours to completely dissolve it.

[0059] Another 30ml Erlenmeyer flask was taken, and 2ml of ethanol, 2ml of glacial acetic acid and 1g of tetrabutyl titanate were added in sequence, and magnetically stirred at 25°C for 20 minutes to make it evenly mixed.

[0060] Take another 30ml Erlenmeyer flask, add 0.75g of barium acetate into 1ml of deionized water, and stir until completely dissolved. Then add the dissolved barium solution into the mixed ester solution, and magnetically stir for 20 minutes at 25° C. to make the solution evenly mixed. Finally, add this mixed solution into the polymer solution, and continue magnetic stirring at 25°C for 20 minutes to make the solution evenly mixed;

[0061] The mixed solution is put into a plastic spinneret, the inner diameter of the plastic spinneret is 1mm, the copper wire is used as the anode, the alum...

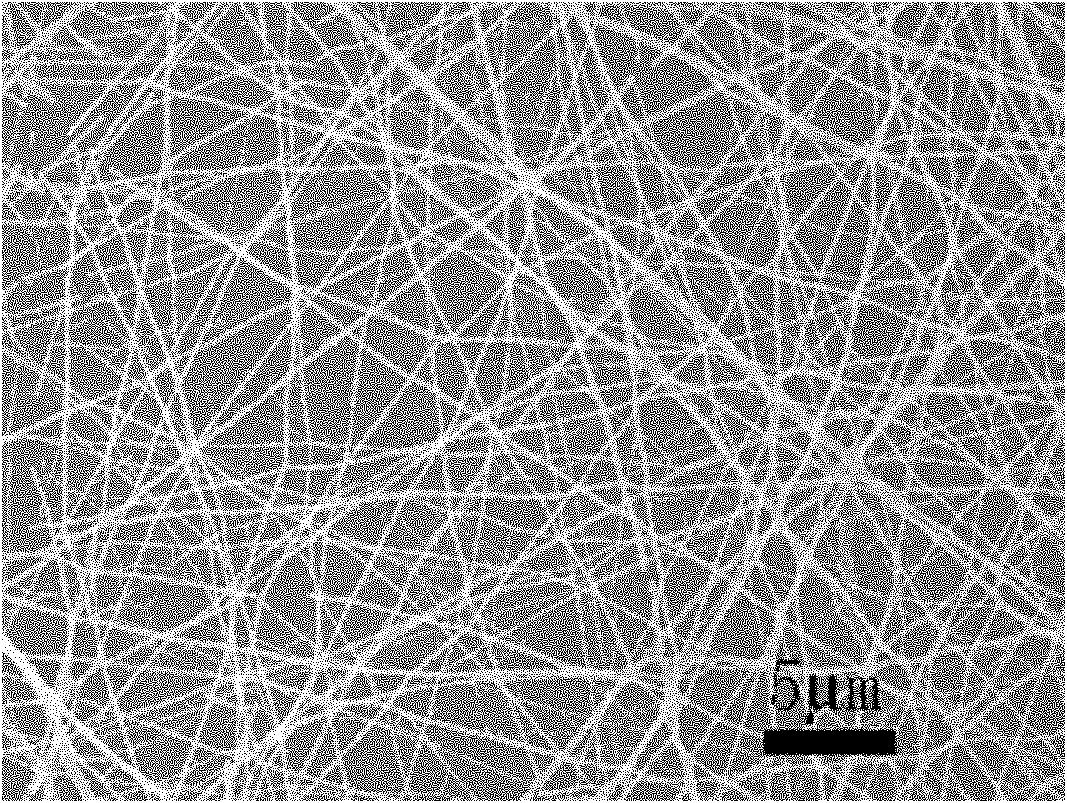

Embodiment 3

[0063] In a 30ml Erlenmeyer flask, 1.0g of polyvinylpyrrolidone was added into 3ml of DMF, and magnetically stirred at 25°C for 4 hours to completely dissolve it.

[0064] Another 30ml Erlenmeyer flask was taken, and 2ml DMF, 2ml glacial acetic acid and 1g tetrabutyl titanate were added in sequence, and magnetically stirred at 25°C for 20 minutes to make it evenly mixed.

[0065] Take another 30ml Erlenmeyer flask, add 0.75g of barium acetate into 1ml of deionized water, and stir until completely dissolved. Then add the dissolved barium solution into the mixed ester solution, and magnetically stir for 20 minutes at 25° C. to make the solution evenly mixed. Finally, add this mixed solution into the polymer solution, and continue magnetic stirring at 25°C for 20 minutes to make the solution evenly mixed;

[0066] Put the mixed solution into a plastic spinneret. The inner diameter of the plastic spinneret is about 1mm. The copper wire is used as the anode, and the aluminum foil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com