Carbonylation method for synthesizing acetic acid by combining rhodium and iridium

A technology for chemical synthesis and rhodium compound, applied in the field of oxo-synthesis of acetic acid by rhodium-iridium combined use, can solve problems such as low activity, achieve the effects of high activity, reduce catalyst cost, and improve catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

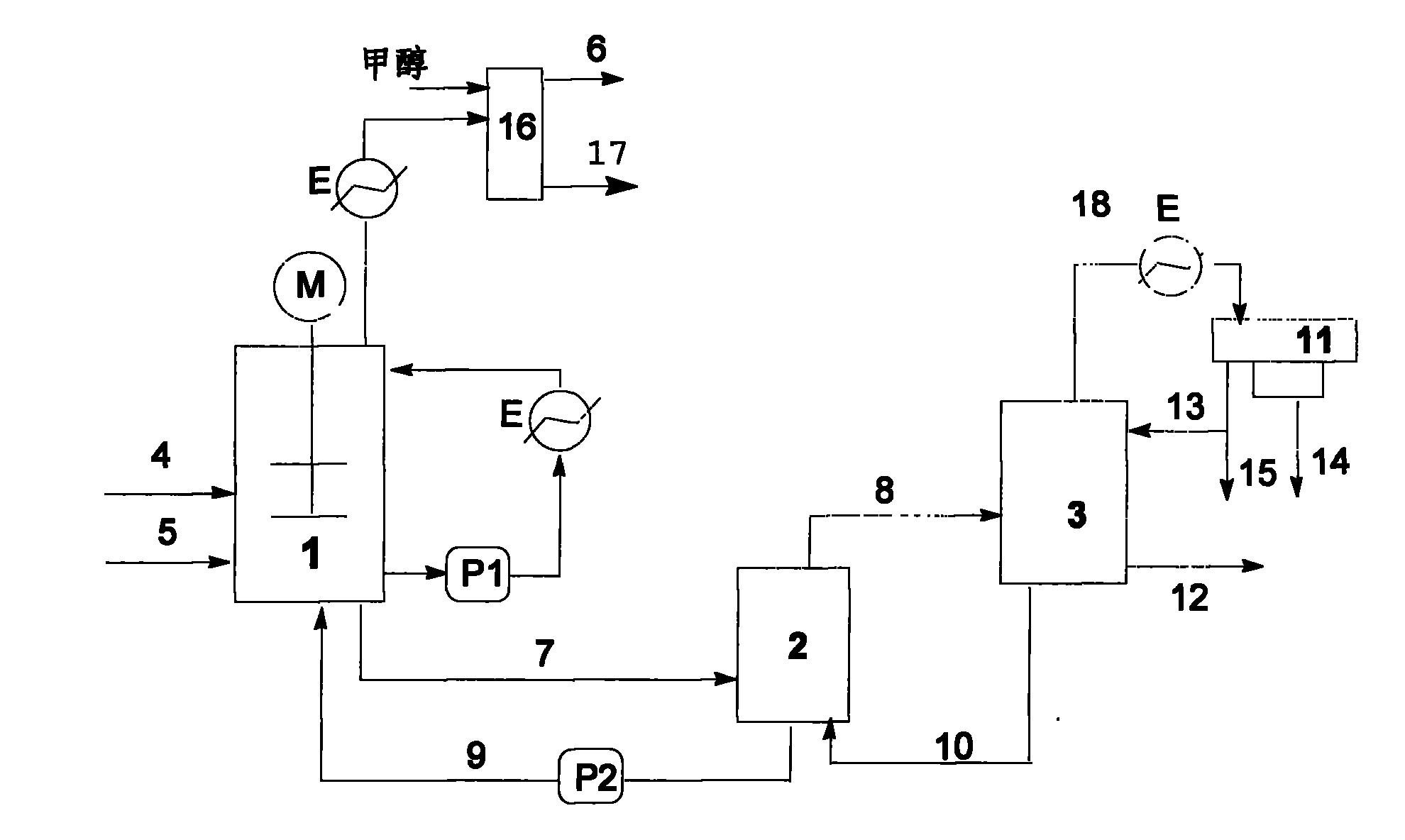

Method used

Image

Examples

Embodiment 1

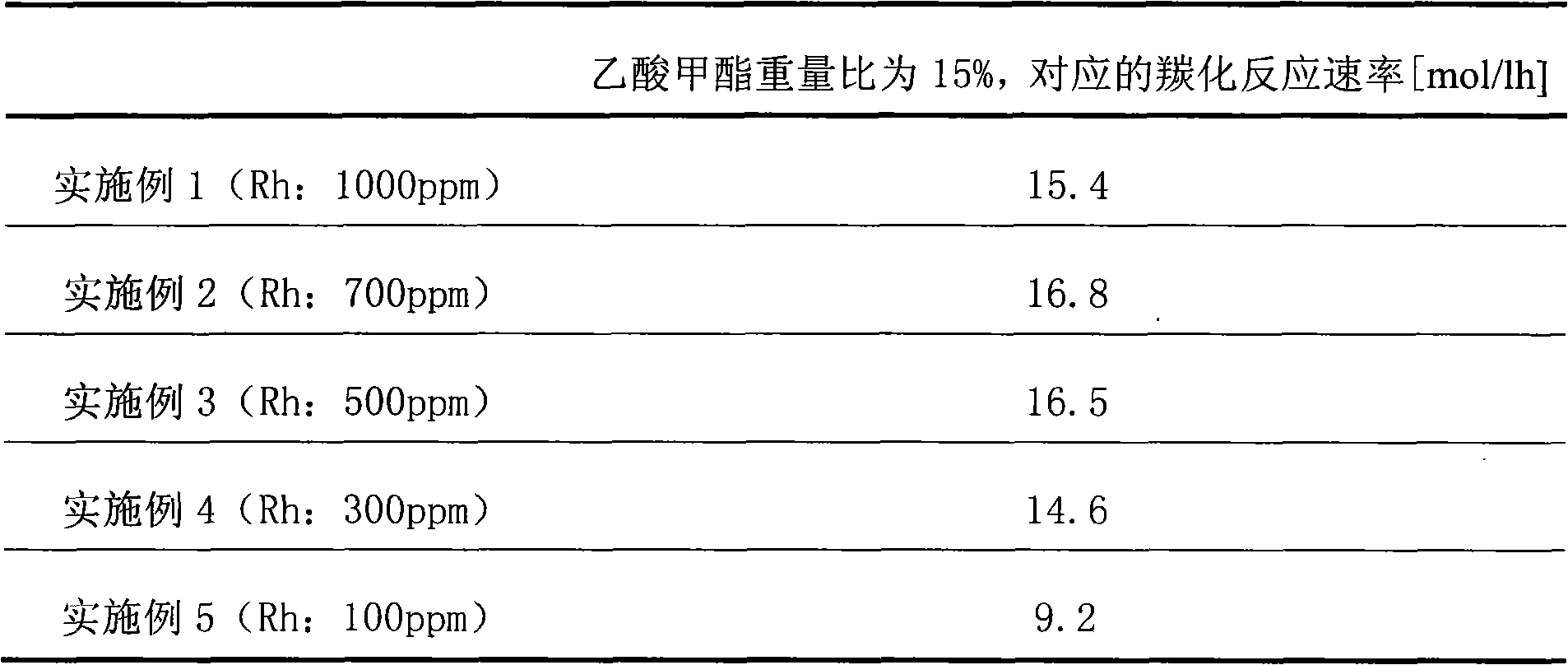

[0027] Add Ir(OAc) to a 250ml zirconium autoclave equipped with a pressure gauge under air atmosphere 3 231mg, the concentration of iridium in the system is 900ppm, RhI 3 630mg, the concentration of rhodium in the system is 1000ppm, ZnI 2 0.934mg, Ir:Zn=1:5 (molar ratio), iodomethane 8.75g, initial concentration is 7%, distilled water 8.75g, initial concentration is 7%, methyl acetate 37.5g, initial concentration is 30% , the rest is 70.0g of acetic acid solvent, keeping the reaction temperature at 190°C and the reaction pressure at 30bar, and reacting to a certain stage of quenching. At this time, the weight ratio of methyl acetate in the reaction solution is 15%.

[0028] The difference between embodiment 2-5 and embodiment 1 is only: the concentration of rhodium in the system is different. See Table 1 for the comparative experiments of changing the rhodium content.

[0029] Table 1

[0030]

Embodiment 6

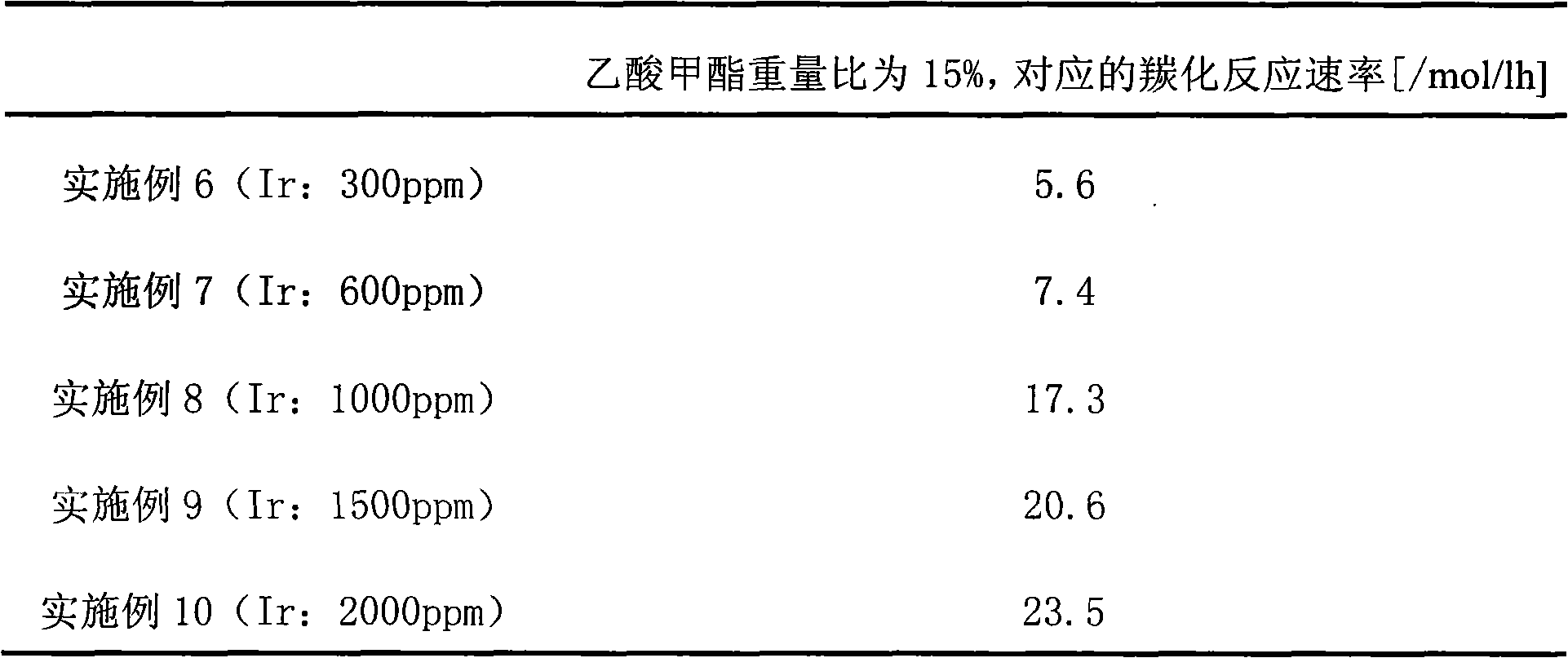

[0032] Add Ir(OAc) to a 250ml zirconium autoclave equipped with a pressure gauge under air atmosphere 3 77mg, the concentration of iridium in the system is 300ppm, RhI 3 189mg, the concentration of rhodium in the system is 300ppm, ZnI 2 0.311mg, Ir: Zn=1:5 (molar ratio), iodomethane 8.75g, initial concentration is 7%, distilled water 8.75g, initial concentration is 7%, methyl acetate 37.5g, initial concentration is 30% , the rest is 70.0g of acetic acid solvent, keeping the reaction temperature at 190°C and the reaction pressure at 30bar, and reacting to a certain stage of quenching. At this time, the weight ratio of methyl acetate in the reaction solution is 15%.

[0033] The only difference between Examples 7-10 and Example 6 is that the concentration of iridium in the system is different. See Table 2 for the comparative experiments of changing the iridium content.

[0034] Table 2

[0035]

Embodiment 11

[0037] Add iridium acetate (iridium content 48%) 231mg in the zirconium material autoclave that pressure gauge is housed in 250ml under air atmosphere, the content of iridium in the system is 900ppm, iodomethane 8.75g, initial mass concentration is 7%, distilled water 8.75g, initial mass concentration 7%, methyl acetate 37.5g, initial mass concentration is 30%, the rest is 70.0g acetic acid solvent, keep reaction temperature 190 ℃, reaction pressure 30bar, react until the weight ratio of methyl acetate is 15 %, the corresponding carbonylation rate is 6mol / Lh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com