High-temperature resistant non-sticking coating

A non-stick coating, high temperature resistant technology, applied in polyester coatings, coatings, etc., can solve the problems affecting the application of non-stick coatings, low resin affinity, poor dispersion performance, etc., to achieve good non-stick performance, solvent resistance, etc. The effect of high performance and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

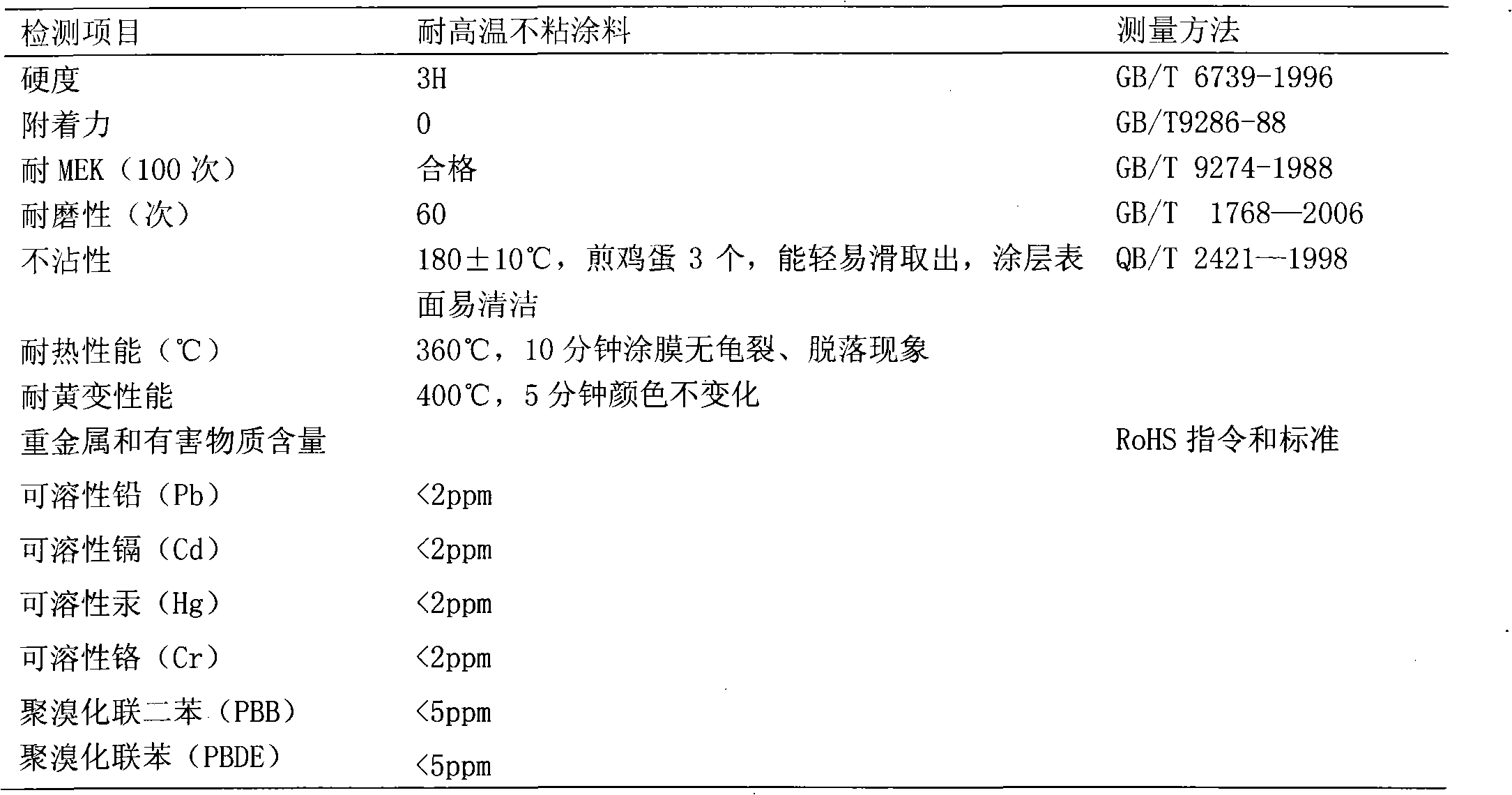

Examples

Embodiment 1

[0030] 1) Synthesis of polyhydroxyl branched saturated polyester

[0031] a) Raw materials:

[0032] Neopentyl glycol 62.4g (0.6mol);

[0033] 2-methyl-1,3 propanediol 27g (0.3mol);

[0034] Trimethylolpropane 13.4g (0.1mol);

[0035] 132.8g (0.8mol) of isophthalic acid;

[0036] b) synthesis steps:

[0037] Add neopentyl glycol, 2-methyl-1,3 propanediol, and trimethylolpropane into a reactor equipped with heating, condensation, and nitrogen protection, and raise the temperature to 160°C under nitrogen protection to melt the polyol; then add Isophthalic acid and 0.4g tetrabutyl titanate were heated and kept at a temperature of 180°C for 4 hours, 220°C for 2 hours, and 240°C for 2 hours; finally cooled to 160°C, adding propylene glycol methyl Ether acetate was used to adjust the solid content to 60%, and cooled to room temperature to obtain 349 g of polyhydroxyl branched saturated polyester with a solid content of 60%.

[0038] c) Performance of polyhydroxyl branched satu...

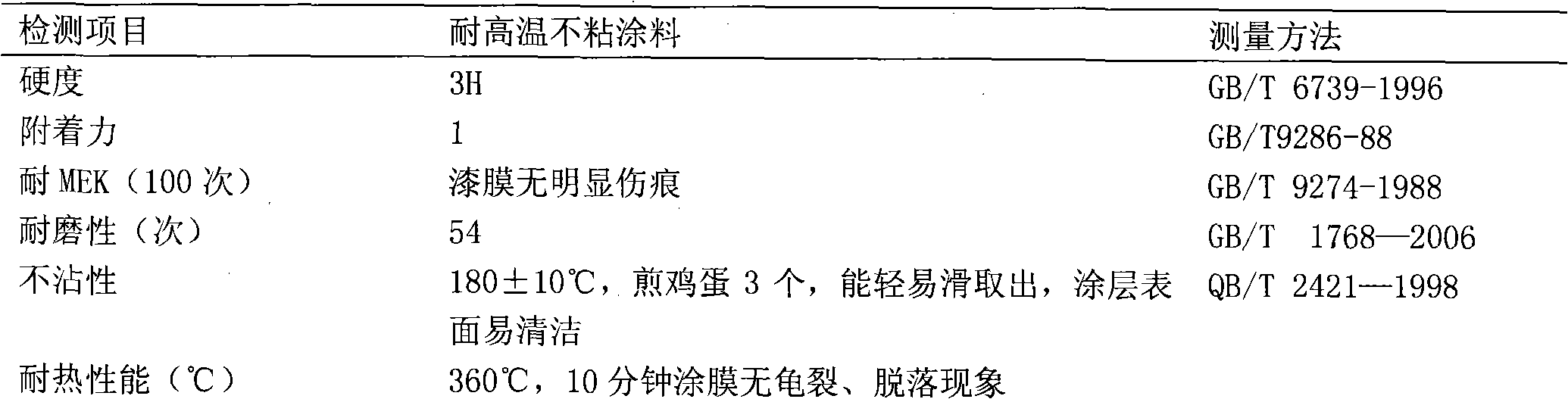

Embodiment 2

[0070] 1) Synthesis of polyhydroxyl branched saturated polyester

[0071] a) Composition:

[0072] Neopentyl glycol 83.2g (0.8mol);

[0073] 13.5g (0.15mol) of 2-methyl-1,3 propanediol;

[0074] Trimethylolpropane 6.7g (0.05mol);

[0075] 149.4g (0.9mol) of isophthalic acid;

[0076] b) synthesis steps:

[0077] Add neopentyl glycol, 2-methyl-1,3 propanediol, and trimethylolpropane into a reactor equipped with heating, condensation, and nitrogen protection, and raise the temperature to 160°C under nitrogen protection to melt the polyol; then add Isophthalic acid and 0.4g tetrabutyl titanate; heated and kept at a temperature of 190°C for 4 hours, then heated to 230°C for 2.5 hours, and heated at 260°C for 2 hours; to reach the theoretical water output 91%, finally cooled to 160°C, adding propylene glycol methyl ether acetate to adjust the solid content to 60%, cooled to room temperature to obtain 347g of polyhydroxy branched saturated polyester with a solid content of 60%....

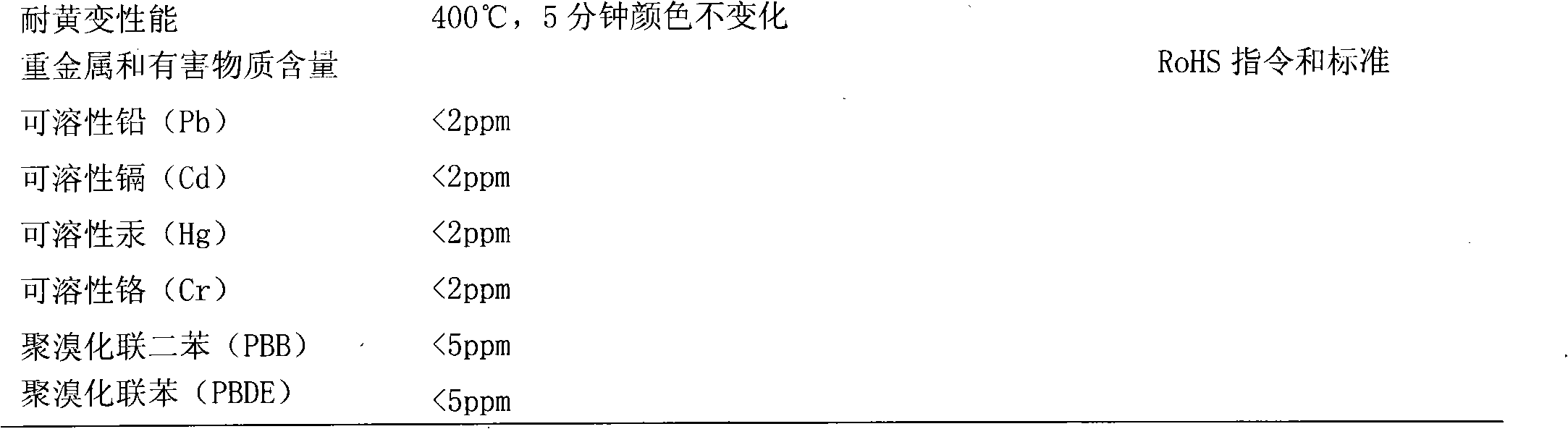

Embodiment 3

[0111] 1) Synthesis of polyhydroxyl branched saturated polyester

[0112] a) Composition:

[0113] Neopentyl glycol 57.2g (0.55mol);

[0114] 2-methyl-1,3 propanediol 31.5g (0.35mol);

[0115] Trimethylolpropane 13.4g (0.1mol);

[0116] Isophthalic acid 141.1g (0.85mol);

[0117] b) synthesis steps:

[0118] Add neopentyl glycol, 2-methyl-1,3 propanediol, and trimethylolpropane into a reactor equipped with heating, condensation, and nitrogen protection, and raise the temperature to 160°C under nitrogen protection to melt the polyol; then add Isophthalic acid and 0.4g of tetraisobutyl titanate are heated and heated at 200°C for 4 hours, 230°C for 2 hours, and 250°C for 2 hours; 95%, finally cooled to 160°C, adding propylene glycol methyl ether acetate to adjust the solid content to 60%, cooled to room temperature to obtain 352g of polyhydroxy branched saturated polyester with a solid content of 60%.

[0119] c) Performance:

[0120] The hydroxyl value of polyhydroxyl branc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com