Adhesive, preparation method and application in integrated circuit board embedment thereof

A technology for adhesives and circuit boards, applied in the direction of adhesives, adhesive additives, printed circuits, etc., can solve the problems of reducing curing stress and modulus, low production efficiency, and large elongation at break, etc., to achieve stress reduction and production High efficiency and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

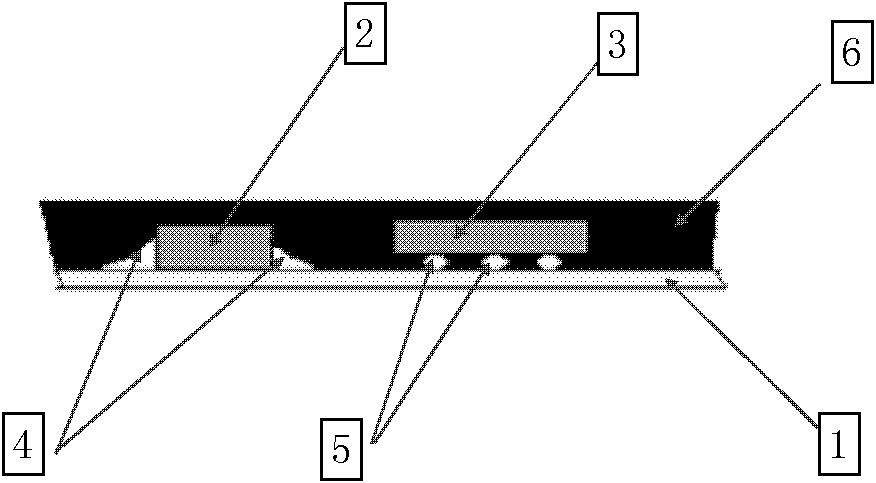

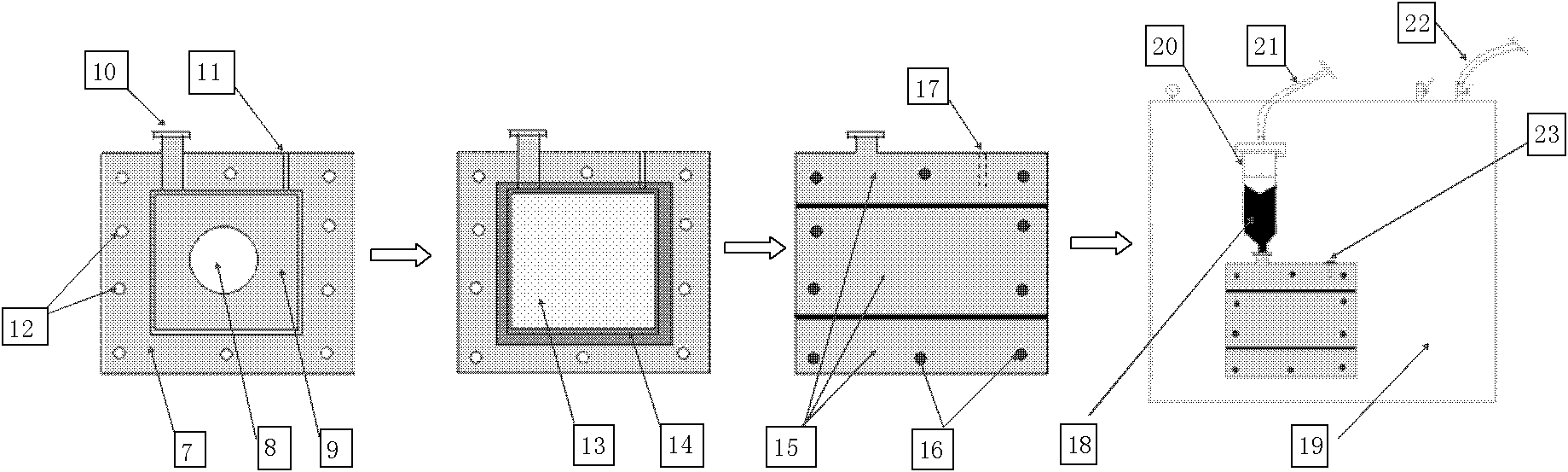

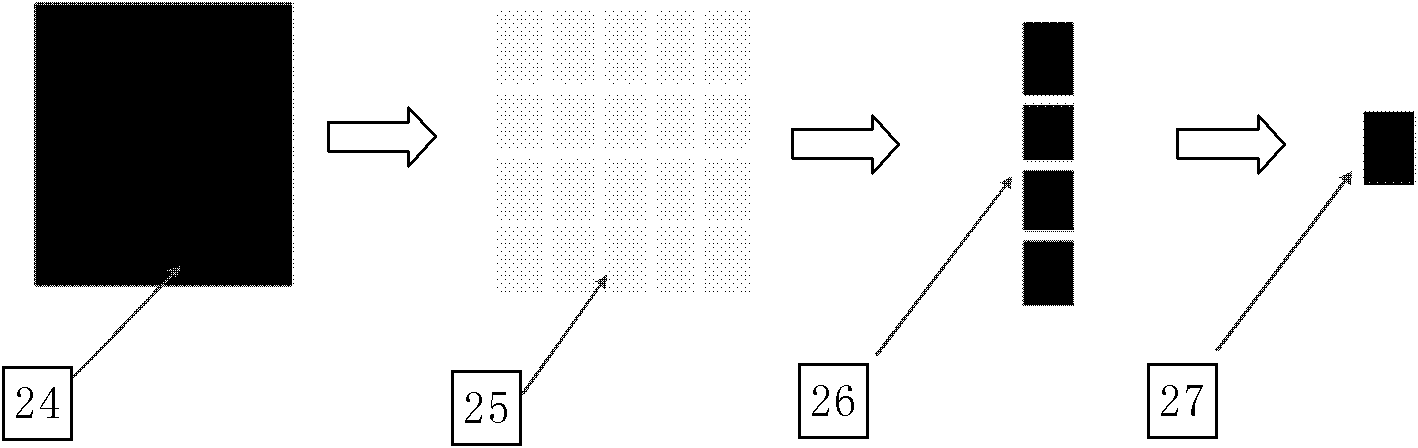

Method used

Image

Examples

Embodiment 1

[0053] An adhesive: including 100 parts of epoxy resin (including 60 parts of liquid bisphenol A epoxy resin and 40 parts of solid bisphenol A epoxy resin), 70 parts of methyl tetrahydrophthalic anhydride, stress absorber 30 parts (including phenylmethyl silicone oil and polytetrafluoroethylene powder), 150 parts of aluminum oxide, 1 part of accelerator (the accelerator is 2-ethyl-4 methylimidazole) and 1 part of additive (wherein, Including 0.2 parts of dispersants such as BYK-163, 0.2 parts of defoamers such as KS-66 and 0.6 parts of carbon black);

[0054] Adhesive preparation method:

[0055] First add the amount of epoxy resin in the mixing tank, heat to 120 ° C, stir until the epoxy resin is completely melted and form a uniform liquid; cool the melted epoxy resin in the mixing tank to room temperature, add the amount of Add additives, and stir evenly; add liquid stress absorber, solid stress absorber, stir evenly, then add curing agent, filler, and stir evenly to obtain...

Embodiment 2

[0070] A kind of adhesive: comprise 100 parts of epoxy resins (wherein, comprise 70 parts of liquid bisphenol A type epoxy resins and 30 parts of solid bisphenol A type epoxy resins), 20 parts of curing agent (wherein, curing agent is formazan tetrahydrophthalic anhydride), 120 parts of stress absorber (including 80 parts of benzyl silicone oil, 30 parts of polytetrafluoroethylene powder and 10 parts of polymethyl methacrylate powder), 200 parts of filler (including trioxide 40 parts of dialuminum, 160 parts of silicon dioxide), 2 parts of accelerator (the accelerator is 2,4,6-(N,N-dimethylaminomethyl)-phenol), 4 parts of additives (including dispersing agent such as BYK-163 1 part, defoamer such as KS-66 1 part and carbon black 2 parts)

[0071] The preparation method of adhesive: preparation method is the same as embodiment 1, and its difference is,

[0072] (1), the heating temperature in the stirring tank is 140°C;

[0073] (2), the mixing time in the planetary mixer is ...

Embodiment 3

[0079] An adhesive: including 100 parts of epoxy resin (including 80 parts of liquid bisphenol A type epoxy resin and 20 parts of liquid bisphenol F type epoxy resin), 50 parts of curing agent (including 80 parts of liquid bisphenol F type epoxy resin), 50 parts of curing agent (including 30 parts of hydrophthalic anhydride, 10 parts of methyl endomethylene tetrahydrophthalic anhydride and 10 parts of tetrahydrophthalic anhydride), 20 parts of stress absorber (including phenylmethyl silicone oil, dimethyl silicone oil and polytetrafluoroethylene ethylene powder), 175 parts of filler (silica as filler), 3 parts of accelerator (1-ethylimidazole as accelerator), 3 parts of additive (including 1 part of dispersant such as BYK-163, defoamer such as 1 part of KS-66 and 1 part of carbon black)

[0080] The preparation method of adhesive: preparation method is the same as embodiment 1, and its difference is,

[0081] (1), the heating temperature in the stirring tank is 90°C;

[0082...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com