Method for preparing carbon-nitrogen-chlorine co-doped nano titanium dioxide photocatalysts

A nano-titanium dioxide and photocatalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high preparation cost, high equipment requirements, complex process, etc. The effect of low equipment requirements and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

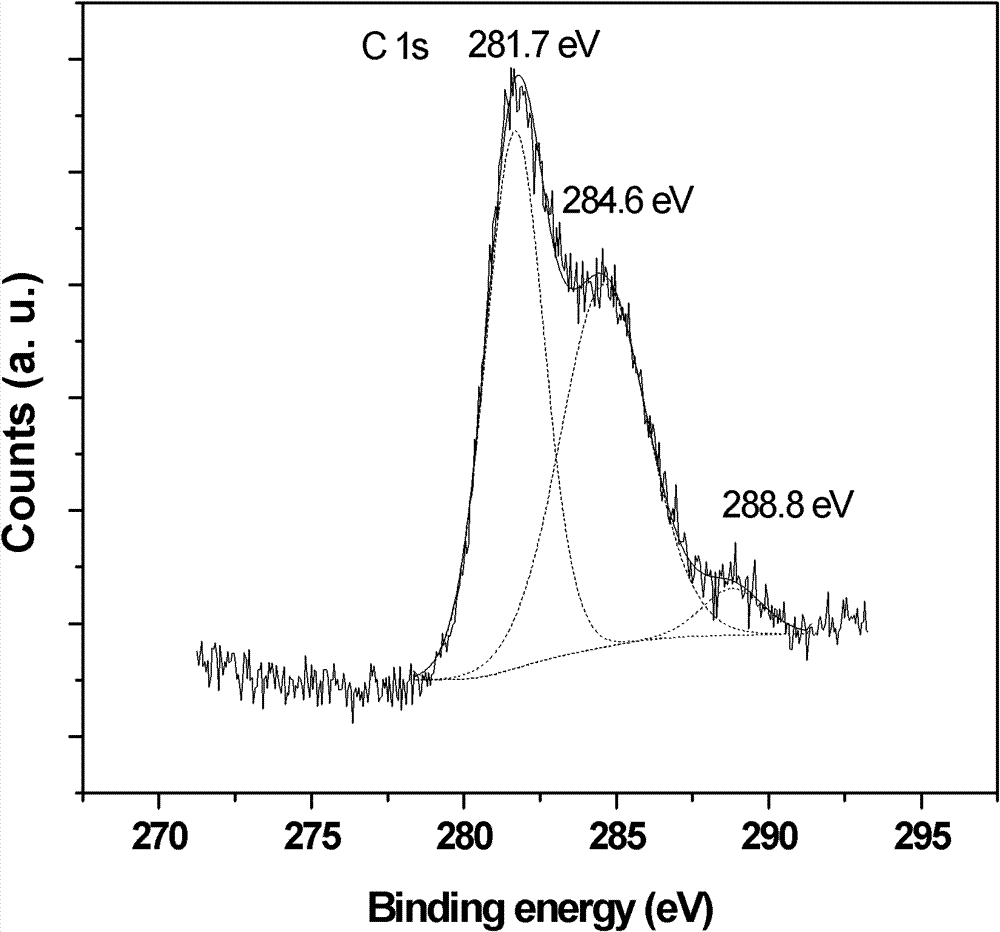

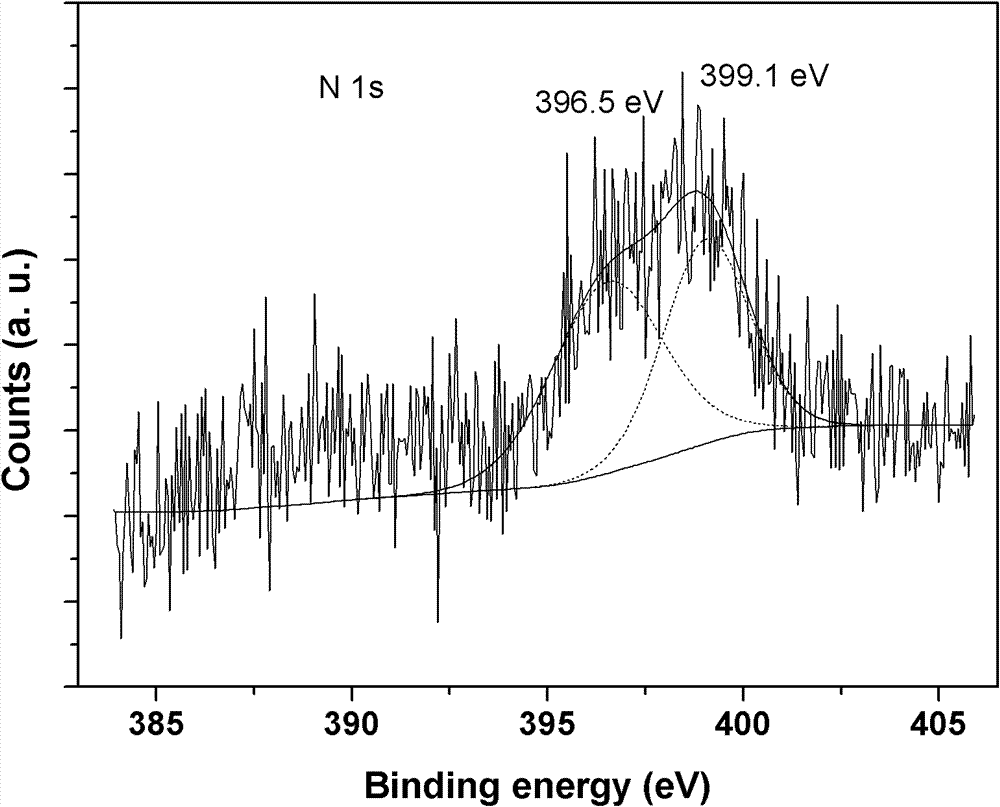

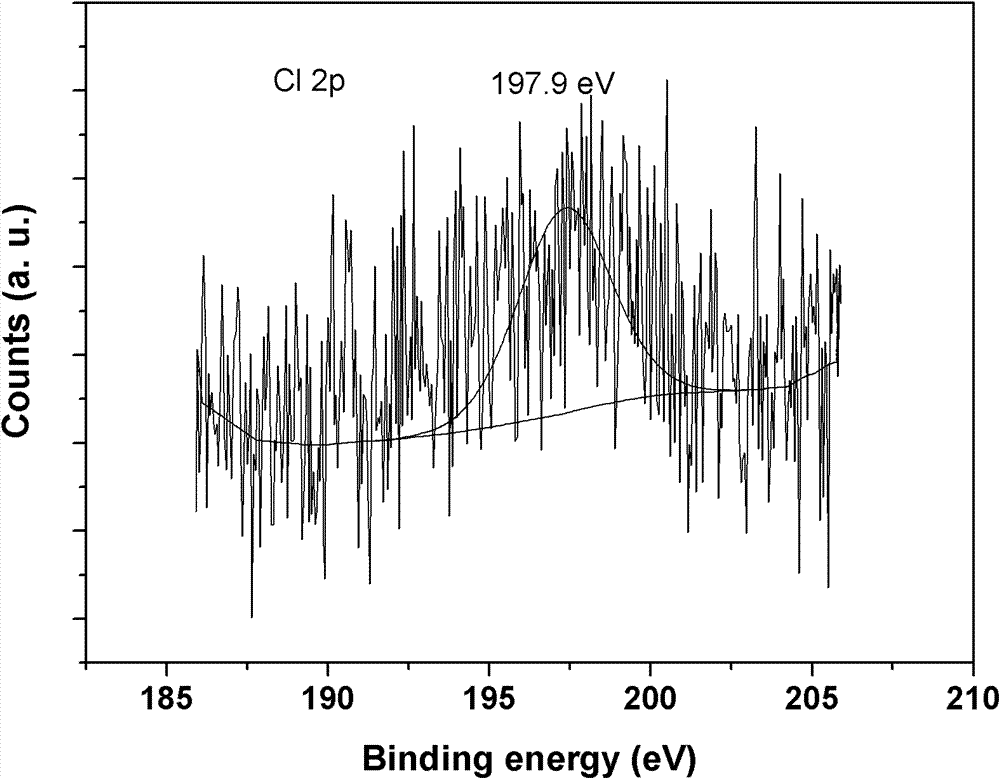

[0023] Embodiment 1 Preparation of carbon-nitrogen-chlorine co-doped nano-titanium dioxide photocatalyst

[0024] Step 1: adding titanium tetrachloride to ice water to form a transparent titanium tetrachloride solution, wherein the volume ratio of titanium tetrachloride and water is 1:20.

[0025] Step 2: After adding ammonia water in step 1, a white precipitate is produced. The molar ratio of the amount of ammonia added to titanium tetrachloride is 4:1.

[0026] Step 3: Filter the white precipitate obtained in step 2, wash with deionized water for 3 to 5 times, and bake at 80°C for 12 hours to obtain amorphous TiO 2 Powder.

[0027] Step 4: Mix the powder obtained in step 3 with glucose in a mass ratio of 1:0.25, then calcinate at 250°C for 3 hours, cool and grind to obtain carbon-nitrogen-chlorine co-doped nano-titanium dioxide with a particle size of less than 20nm Powder.

Embodiment 2

[0028] Embodiment 2 Preparation of carbon-nitrogen-chlorine co-doped nano-titanium dioxide photocatalyst

[0029] Step 1: adding titanium tetrachloride to ice water to form a transparent titanium tetrachloride solution, wherein the volume ratio of titanium tetrachloride and water is 1:20.

[0030] Step 2: After adding ammonia water in step 1, a white precipitate is produced. The molar ratio of the amount of ammonia added to titanium tetrachloride is 4:1.

[0031] Step 3: Filter the white precipitate obtained in step 2, wash with deionized water for 3 to 5 times, and bake at 80°C for 12 hours to obtain amorphous TiO 2 Powder.

[0032] Step 4: Mix the powder obtained in step 3 with glucose evenly at a mass ratio of 1:0.25, then calcinate at 300°C for 3 hours, cool and grind to obtain carbon-nitrogen-chlorine co-doped nano-titanium dioxide with a particle size of less than 20nm Powder.

[0033] The carbon-nitrogen-chlorine co-doped nano-titanium dioxide powder prepared in Examp...

Embodiment 3

[0034] The preparation of the nano titanium dioxide photocatalyst of embodiment 3 carbon-nitrogen-chlorine co-doping

[0035] Step 1: adding titanium tetrachloride to ice water to form a transparent titanium tetrachloride solution, wherein the volume ratio of titanium tetrachloride and water is 1:20.

[0036] Step 2: After adding ammonia water in step 1, a white precipitate is produced. The molar ratio of the amount of ammonia added to titanium tetrachloride is 4:1.

[0037] Step 3: Filter the white precipitate obtained in step 2, wash with deionized water for 3 to 5 times, and bake at 80°C for 12 hours to obtain amorphous TiO 2 Powder.

[0038] Step 4: Mix the powder obtained in step 3 with ammonium chloride and glucose in a mass ratio of 1:0.1:0.25, then calcinate at 300°C for 3 hours, cool and grind to obtain carbon-nitrogen-chlorine with a particle size of less than 20nm Co-doped nano titanium dioxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com