Semiconductor laser device and method of manufacturing the device

A technology of a laser device and a manufacturing method, which is applied to semiconductor lasers, structures of optical waveguide semiconductors, lasers, etc., can solve problems such as deterioration of contact characteristics, damage to functions, changes in conductive characteristics of the laser exit end face, etc., and achieves low operating voltage, long Long life, high output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

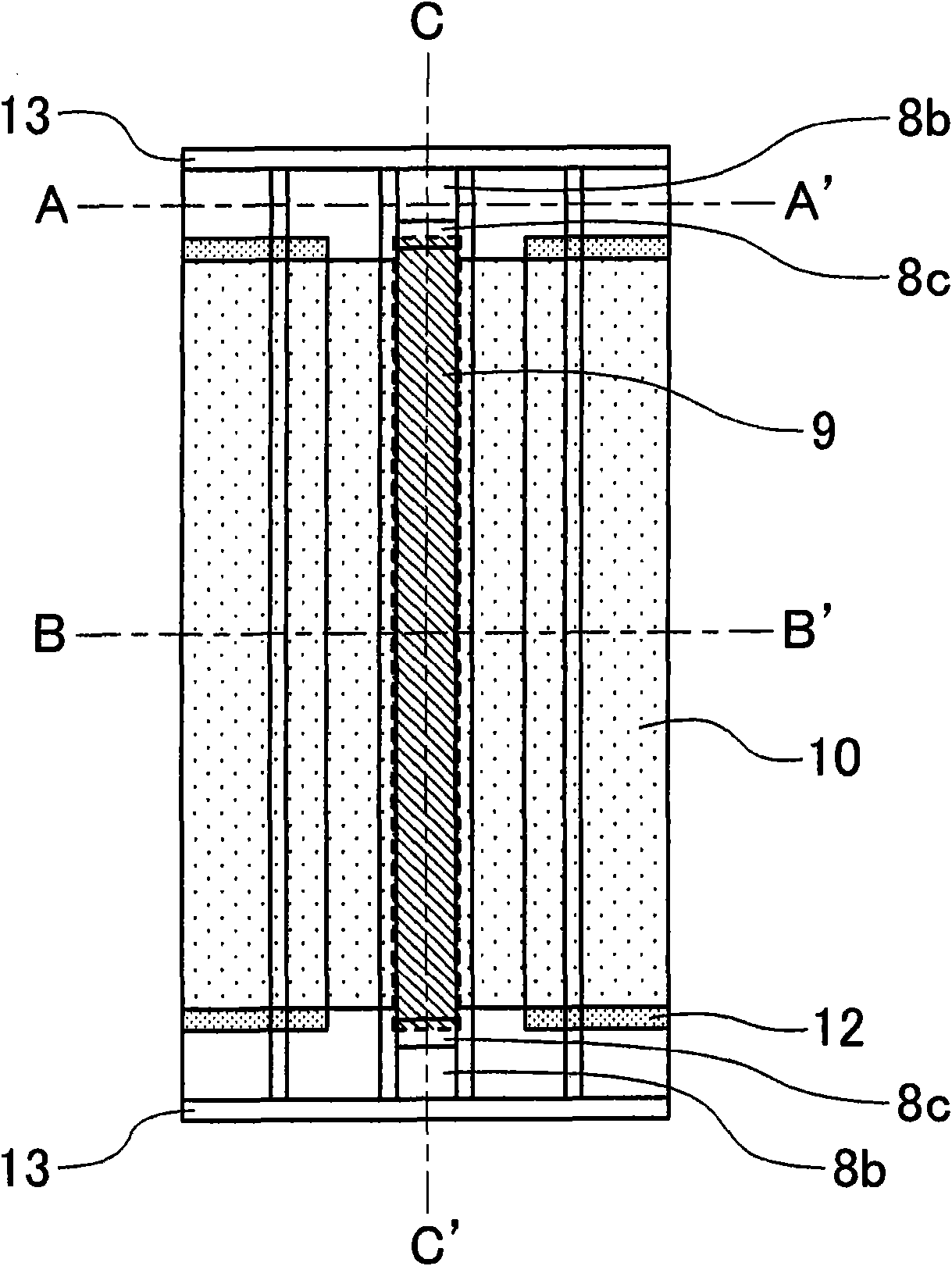

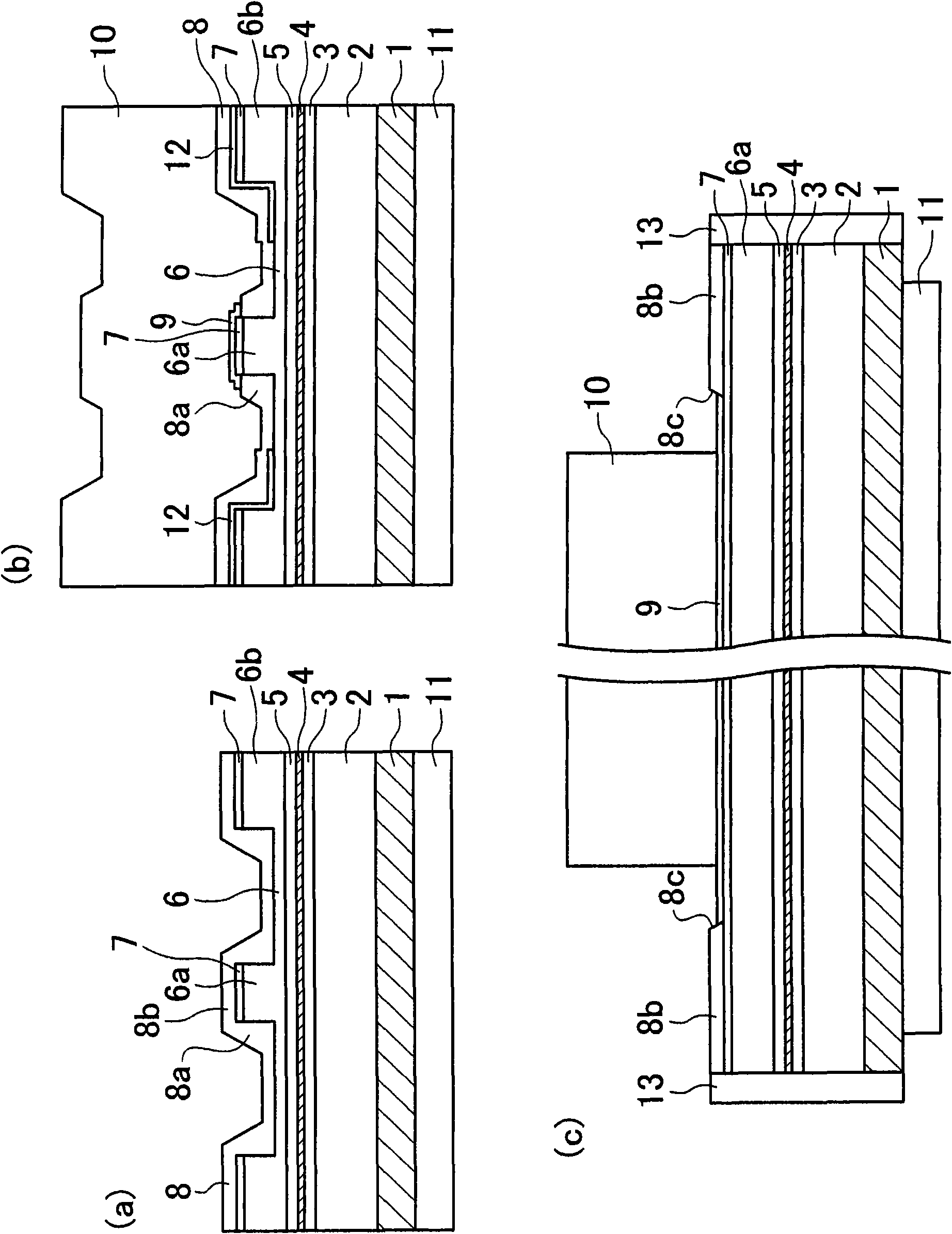

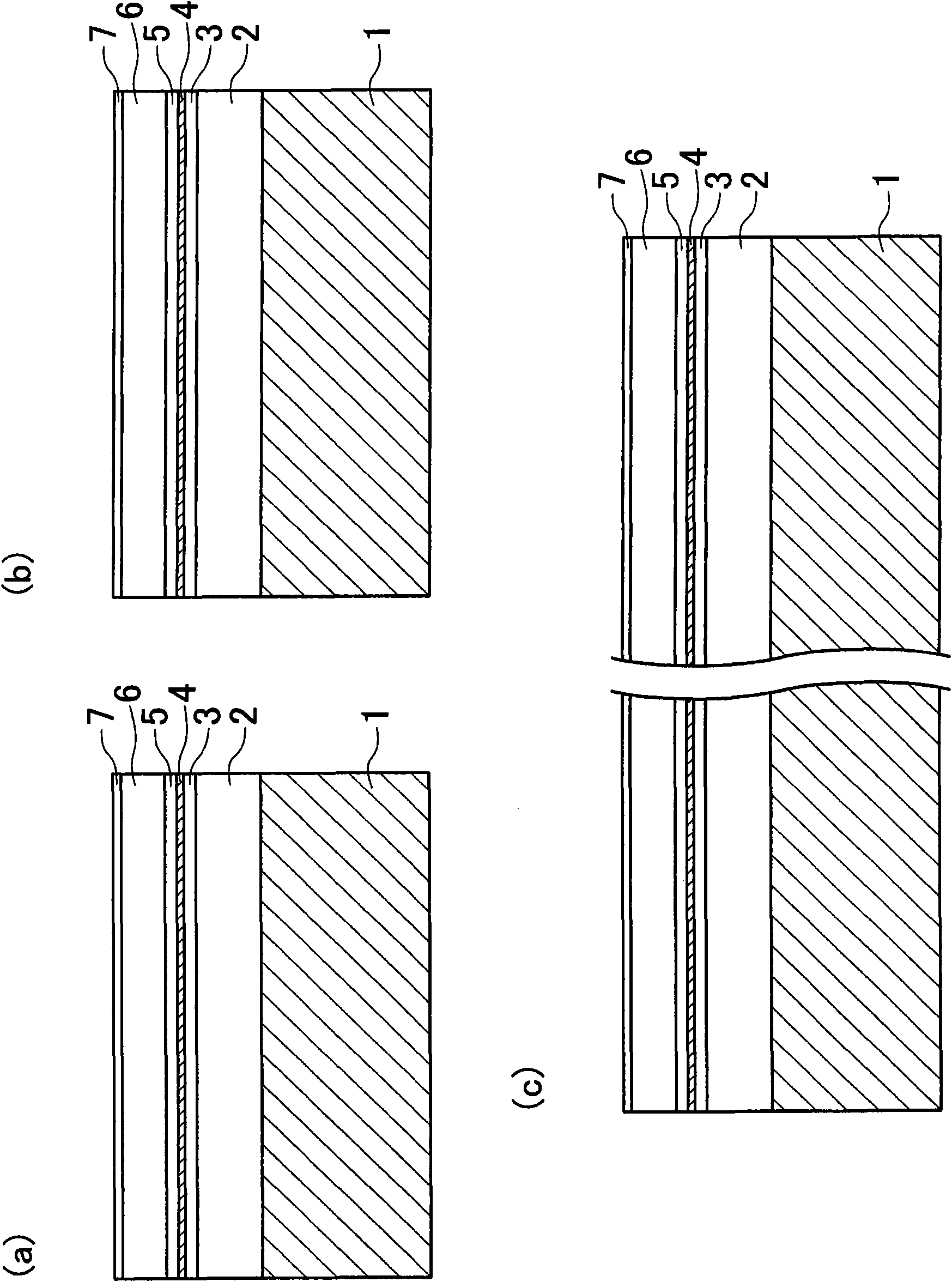

[0069] figure 1 It is a plan view showing the configuration of a semiconductor laser device according to one embodiment, specifically a GaN semiconductor laser diode, figure 2 (a) is figure 1 The cross-sectional view at the A-A' line (current non-injection area), figure 2 (b) is figure 1 The cross-sectional view at the B-B' line (current injection area) of figure 2 (c) is figure 1 The cross-sectional view at the C-C' line (the direction in which the ridge extends).

[0070] Such as figure 1 and figure 2 As shown in (a) to (c), on the n-type GaN substrate 1, for example, a layer made of n-type Al with a thickness of about 2.5 μm is formed. x Ga 1-x An n-type cladding layer 2 composed of N (x=0.03). On the n-type cladding layer 2, there is formed an n-type optical guiding layer 3 made of n-type GaN with a thickness of about 0.1 μm, for example. On the n-type photoguiding layer 3, a multiple quantum well active layer 4 is formed. The multiple quantum well activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com