Organic silicon modified bi-component solvent-based polyurethane anti-corrosive coating and preparation method thereof

A technology of anti-corrosion coating and modified polyester, which is applied in the direction of polyurea/polyurethane coating, anti-corrosion coating, coating, etc., can solve the problems of high cost, anti-corrosion failure of chimneys, etc., and achieve the reduction of internal stress, easy anti-corrosion construction, high solid The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

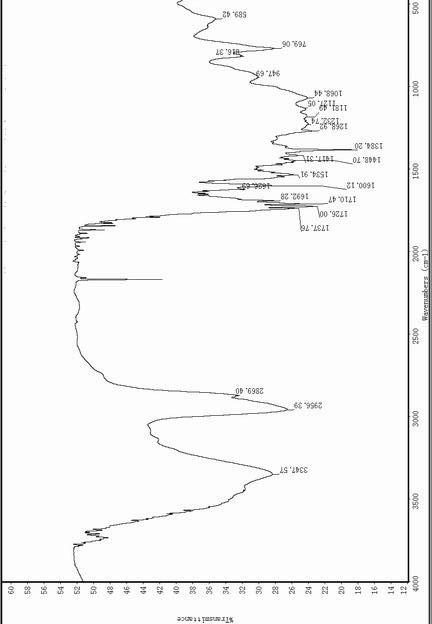

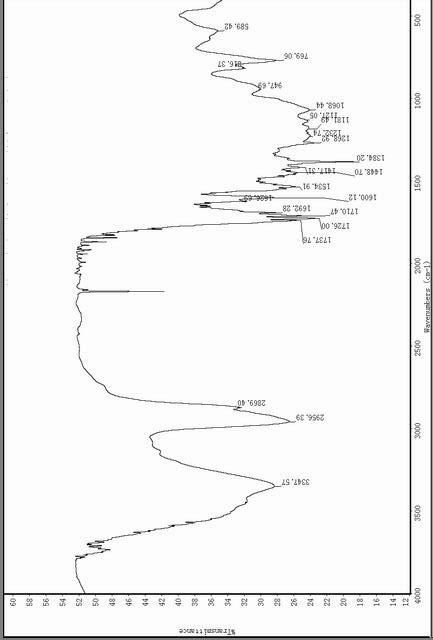

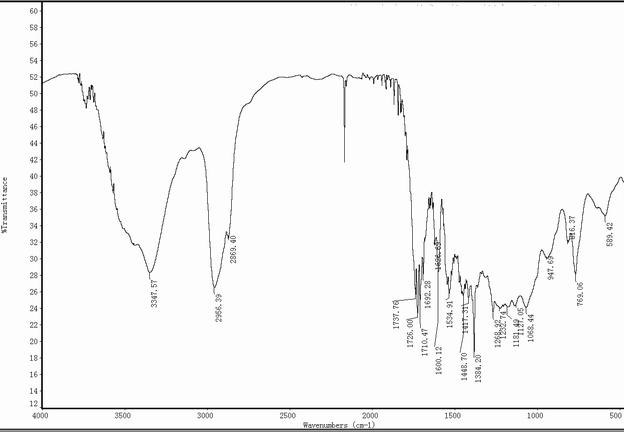

Image

Examples

Embodiment 1

[0038] a. Preparation of organosilicon oligomer: the raw materials of each composition are calculated by mass percentage: 60% of silane coupling agent, 10% of deionized water, and 30% of absolute ethanol.

[0039] Add 60% silane coupling agent and 15% absolute ethanol to the three-necked flask, and after the temperature rises to 70°C, add a mixed solution of 10% deionized water and 15% absolute ethanol dropwise, and control the dropping speed within half an hour finished adding. After continuing the reaction for 3 hours, the reaction was stopped. Then distill at normal pressure, and stop the distillation after the temperature of the remaining liquid in the bottle rises to 125°C. Silicone oligomers were prepared.

[0040] b. Preparation of organosilicon-modified polyester polyol: the raw materials of each composition are calculated by mass percentage: 10% of organosilicon oligomer, 35% of polyester polyol, and 55% of mixed solvent.

Embodiment 2

[0047] a. Preparation of organosilicon oligomer: the raw materials for each composition are calculated by mass percentage: 65% of silane coupling agent, 5% of deionized water, and 30% of absolute ethanol.

[0048] Add 65% silane coupling agent and 20% absolute ethanol to the three-necked flask. After the temperature rises to 60°C, add a mixed solution of 5% deionized water and 10% absolute ethanol dropwise, and control the dropping speed within half an hour. finished adding. The reaction was continued for 4 hours, and the reaction was stopped. Then distill at normal pressure, and stop the distillation after the temperature of the remaining liquid in the bottle rises to 105°C. Silicone oligomers were prepared.

[0049] b. Preparation of organosilicon-modified polyester polyol: the raw materials of each composition are calculated by mass percentage: 13% of organosilicon oligomer, 37% of polyester polyol, and 50% of mixed solvent.

[0050] Add silicone oligomer, polyester poly...

Embodiment 3

[0056] a. Preparation of organosilicon oligomer: the raw materials for each composition are calculated by mass percentage: 40% of silane coupling agent, 15% of deionized water, and 45% of absolute ethanol.

[0057] Add 40% silane coupling agent and 20% absolute ethanol to the three-necked flask. After the temperature rises to 63°C, add a mixed solution of 15% deionized water and 25% absolute ethanol dropwise, and control the dropping speed within half an hour. finished adding. After continuing the reaction for 3 hours, the reaction was stopped. Then distill at normal pressure, and stop the distillation after the temperature of the remaining liquid in the bottle rises to 110°C. Silicone oligomers were prepared.

[0058] b. Preparation of organosilicon-modified polyester polyol: the raw materials of each composition are calculated by mass percentage: 15% of organosilicon oligomer, 35% of polyester polyol, and 50% of mixed solvent.

[0059] Add silicone oligomer, polyester pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com