Vacuum aluminizing/cathode electrophoresis composite protective technique for NdFeB magnet and NdFeB magnet with composite protective layer

A technology of cathodic electrophoresis and vacuum aluminum plating, used in vacuum evaporation plating, electrophoresis plating, magnetic objects, etc. Focus on improving and meeting the effect of market requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

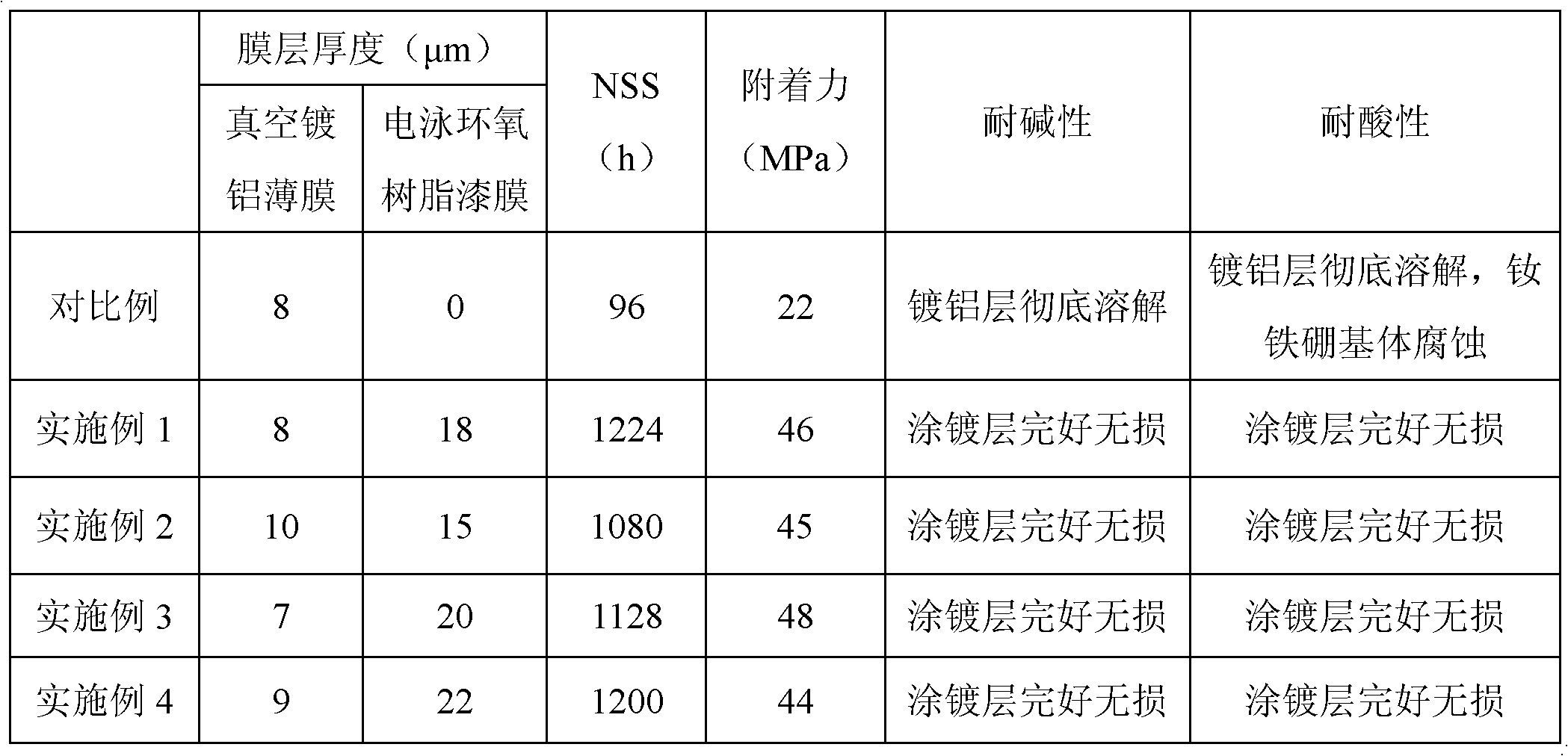

Examples

Embodiment 1

[0036] (1) Degreasing: put the NdFeB magnet with a size of 10×10×10mm into the alkaline degreasing liquid, and degrease at a temperature of 65°C for 10 minutes to remove the oil stain on the surface of the magnet. The formula of the degreasing liquid used is:

[0037] Sodium carbonate (Na 2 CO 3 ) 25g / l sodium phosphate (Na 3 PO 4 .12H 2 O) 10g / l

[0038] Sodium silicate (Na 2 SiO 3 ) 5g / l Surfactant 1~2ml / l pH: 9~10

[0039] (2) Rust removal: Put the magnet in the rust removal solution and soak it at room temperature for 25s to remove the oxide film on the surface of the magnet. The formula of the rust removal solution used is:

[0040] Nitric acid (65%) 70~80ml / l Corrosion inhibitor 0.5~1%

[0041] (3) Vacuum aluminum plating: put the magnet into the vacuum coating chamber, start the vacuum pump to evacuate the coating chamber, and heat the NdFeB magnet to keep the temperature at 280°C. When the vacuum degree reaches 5×10 -3 At the same time, the magnet is aluminum-...

Embodiment 2

[0050] (1) Degreasing: put the NdFeB magnet with a size of 10×10×10mm into the alkaline degreasing liquid, and degreasing at a temperature of 50°C for 15 minutes to remove the oil on the surface of the magnet. The formula of the degreasing liquid used is:

[0051] Sodium carbonate (Na 2 CO 3 ) 25g / l sodium phosphate (Na 3 PO 4 .12H 2 O) 10g / l

[0052] Sodium silicate (Na 2 SiO 3 ) 5g / l Surfactant 1~2ml / l pH: 9~10

[0053] (2) Rust removal: Put the magnet in the rust removal solution and soak it at room temperature for 20s to remove the oxide film on the surface of the magnet. The formula of the rust removal solution used is:

[0054] Nitric acid (65%) 70~80ml / l Corrosion inhibitor 0.5~1%

[0055] (3) Vacuum aluminum plating: Put the magnet into the vacuum coating chamber, start the vacuum pump to evacuate the coating chamber, and heat the NdFeB magnet to keep the temperature at 260 °C. When the vacuum degree reaches 4×10 -3At the same time, the magnet is aluminum-coat...

Embodiment 3

[0064] (1) Degreasing: put the NdFeB magnet with the size of 10×10×10mm into the alkaline degreasing liquid, and degreasing at a temperature of 65°C for 5 minutes to remove the oil on the surface of the magnet. The formula of the degreasing liquid used is:

[0065] Sodium carbonate (Na 2 CO 3 ) 25g / l sodium phosphate (Na 3 PO 4 .12H 2 O) 10g / l

[0066] Sodium silicate (Na 2 SiO 3 ) 5g / l Surfactant 1~2ml / l pH: 9~10

[0067] (2) Rust removal: Put the magnet in the rust removal solution and soak it at room temperature for 20s to remove the oxide film on the surface of the magnet. The formula of the rust removal solution used is:

[0068] Nitric acid (65%) 70~80ml / l Corrosion inhibitor 0.5~1%

[0069] (3) Vacuum aluminum plating: Put the magnet into the vacuum coating chamber, start the vacuum pump to evacuate the coating chamber, and heat the NdFeB magnet to keep the temperature at 280°C. When the vacuum degree reaches 6×10 -3 At the same time, the magnet is aluminum-coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com