Three-laminated-layer thin film solar cell and preparation method thereof

A solar thin film and triple junction stacking technology, applied in the field of solar cells, can solve the problems such as the inability of solar thin film cells to achieve broad-spectrum absorption, the easy generation of S-W effect by amorphous silicon, and the reduction of the efficiency of solar thin film cells, so as to improve the photoelectric conversion efficiency. , the effect of increasing the band gap width and expanding the spectral absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

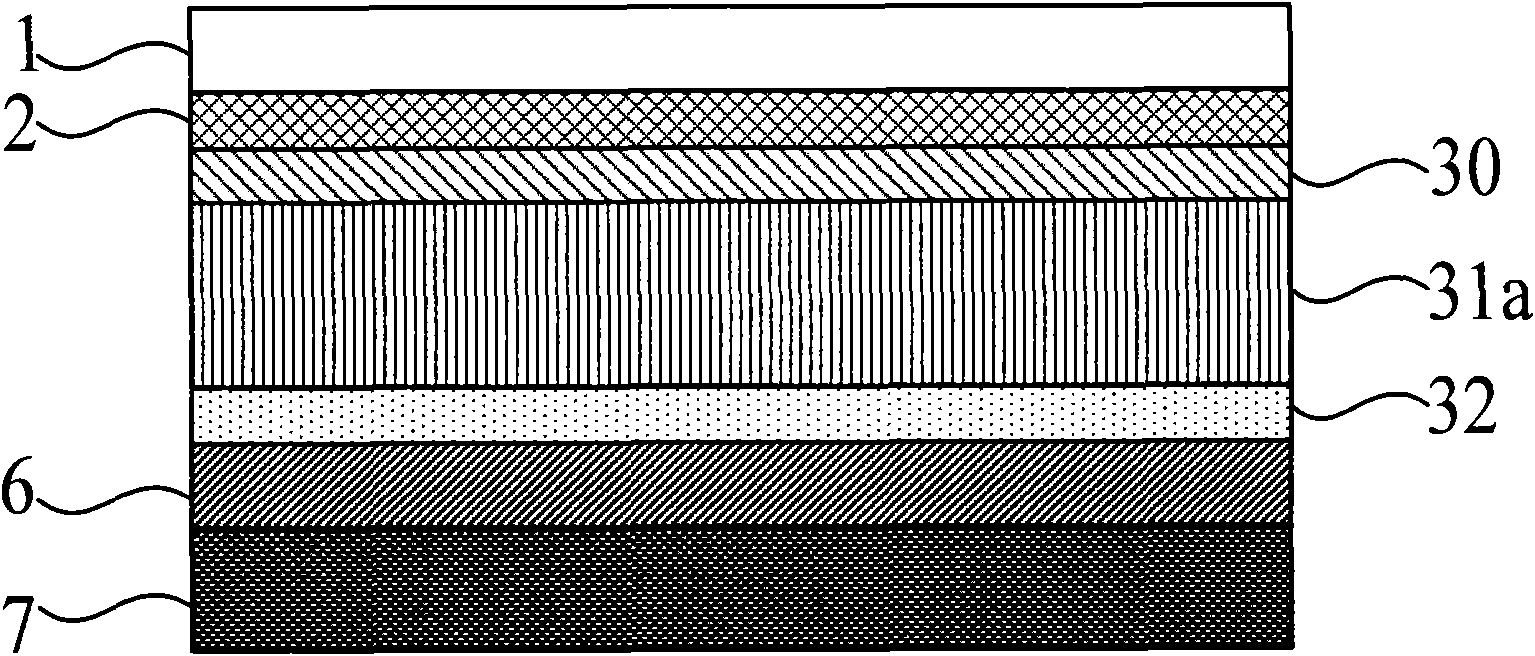

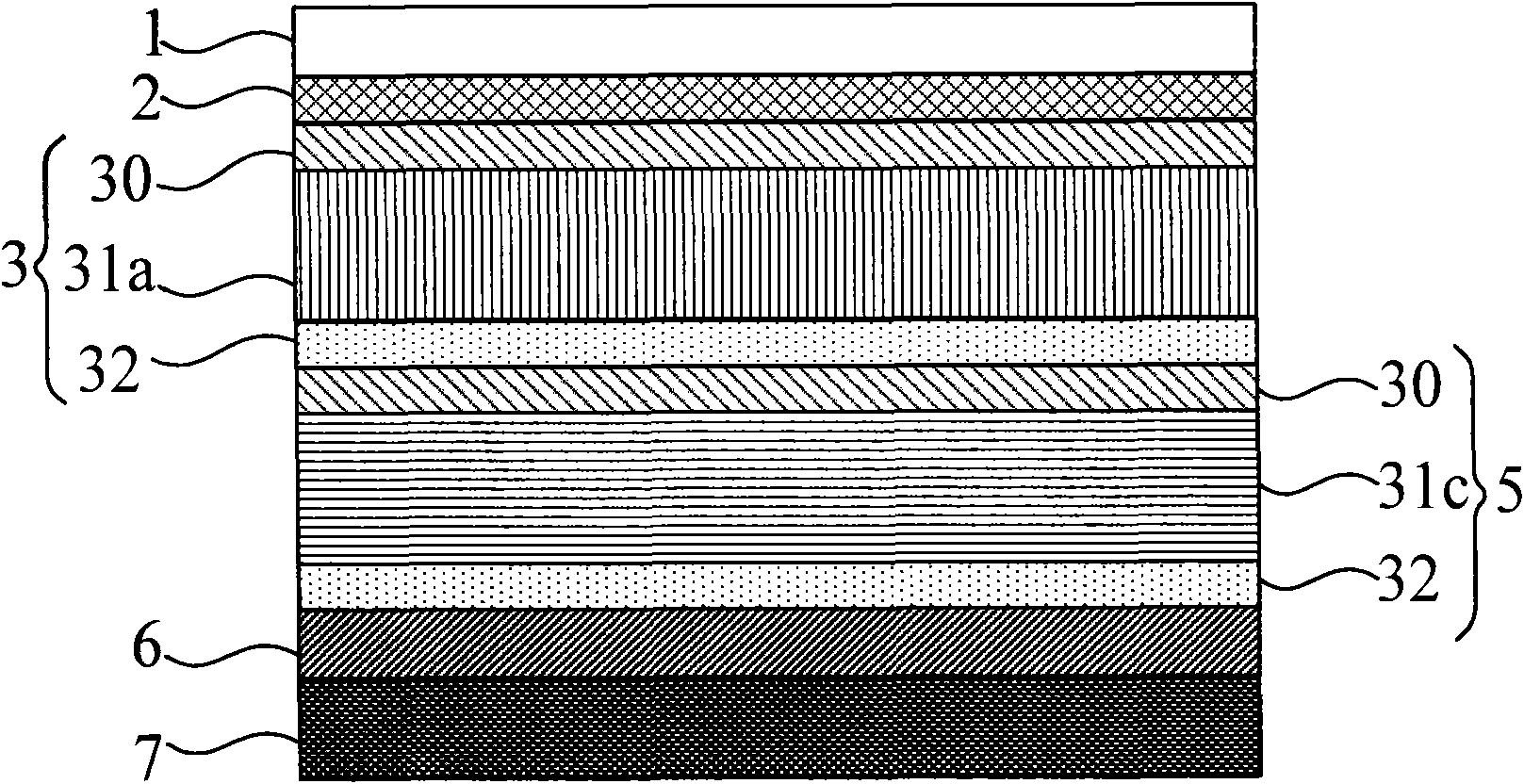

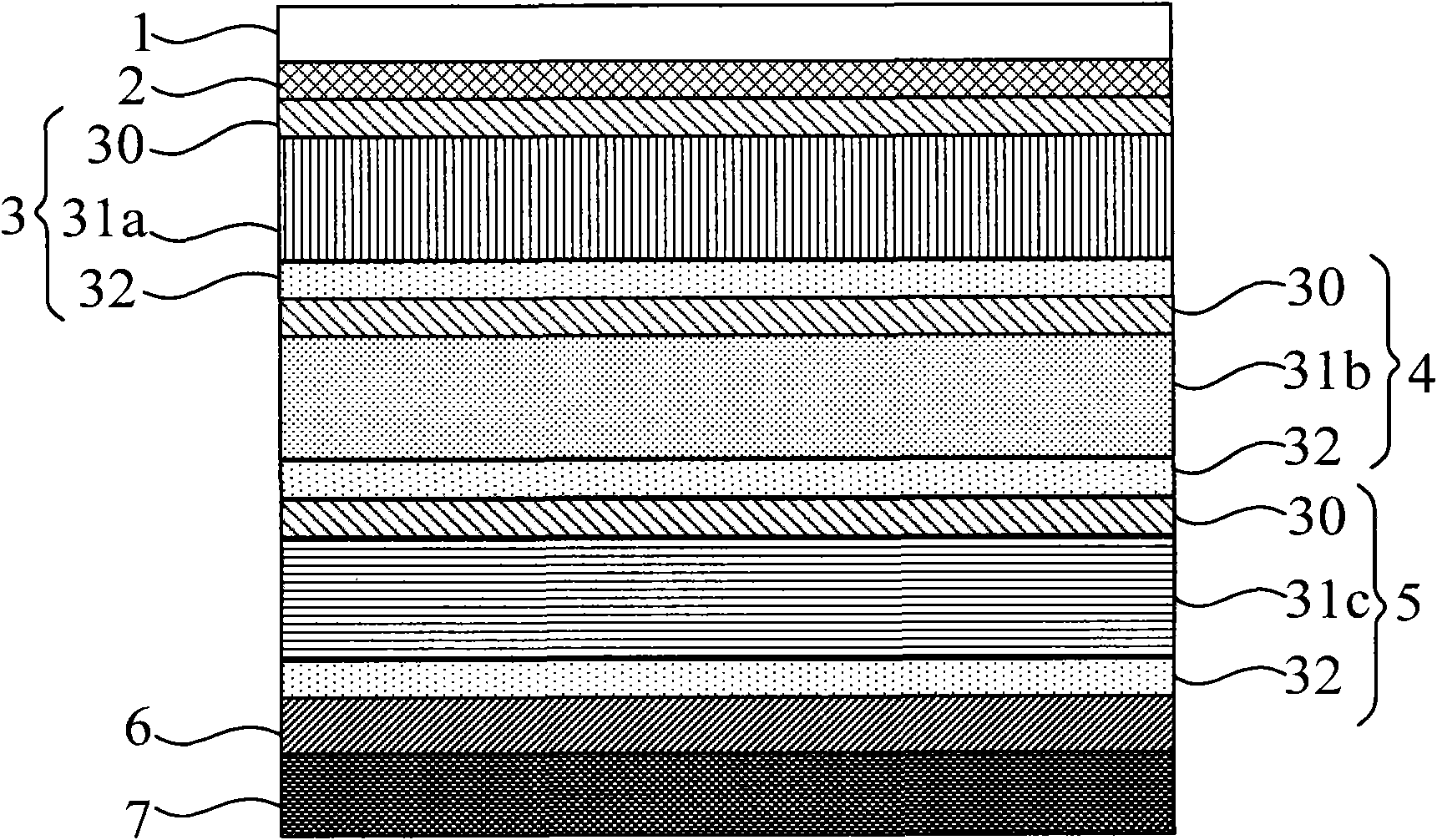

[0036] Figure 4 The structure schematic diagram of the three-junction laminated solar thin film battery provided for Embodiment 1 of the present invention, it can be seen from the figure that the triple-junction laminated solar thin film battery includes a top battery 3, a middle battery 4 and a bottom battery 5, respectively comprising P-type doped layer, intrinsic layer and N-type doped layer, wherein,

[0037] The intrinsic layer of the top cell 3 is an intrinsic nano-silicon film 31d with a grain size of 2-10 nanometers (nm) and a crystallization rate of 10-20%.

[0038] In the present invention, nano-silicon with a grain size of 2-10nm and a crystallization rate of 10-20% is used as the intrinsic layer of the top cell 3, that is, the intrinsic nano-silicon thin film 31d. Therefore, the bandgap width of the top battery 3 is increased to 1.8-2.0ev, so that the solar thin film battery can fully absorb the spectrum with a wavelength less than 400nm, and at the same time, be...

Embodiment 2

[0047] This embodiment provides a method for preparing a triple-junction stacked solar thin film cell, which includes the process of sequentially forming a transparent conductive film, a top cell, an intermediate cell, a bottom cell, a back reflection electrode and a metal back electrode on a transparent substrate. Figure 5 The flow chart of forming the top cell in the preparation method of the triple-junction laminated solar thin film cell provided in Example 2 of the present invention, from Figure 5 As can be seen in the figure, the process of forming the top cell includes:

[0048] Step 100, depositing a boron-doped amorphous silicon carbon layer on the transparent conductive film;

[0049] Step 200, on the boron-doped amorphous silicon carbon layer, using a mixed gas of silane and hydrogen with a silane concentration of 1-5%, at a deposition pressure of 1.0-1.5 Torr (Torr), a deposition temperature of 180-220° C. and Under the glow power of 15-30W, the intrinsic nano-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com