Preparation method and purpose of top cell P type layer of amorphous silicon germanium thin-film solar cell

A technology of thin-film solar cells and amorphous silicon germanium, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of lower open-circuit voltage of the top cell, affect the photoelectric conversion efficiency of the cell, limit current output, etc., and achieve optimal current matching, Effects of improving photoelectric conversion efficiency and increasing open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

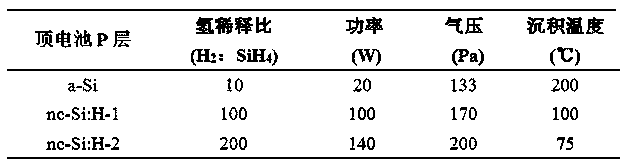

Method used

Image

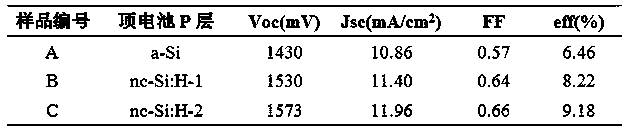

Examples

Embodiment 1

[0017] Using a flexible polyimide substrate with a thickness of 25 mm, the N-I-P structure bilayer was deposited on the substrate with an Ag / ZnO composite back reflection layer by plasma-assisted chemical vapor deposition (PECVD, operating frequency at 13.56 MHz). Amorphous silicon germanium thin film (a-Si:H / a-SiGe:H), in which the reaction gas of the N layer is hydrogen, silane and phosphine, and the thickness is about 50 nm; the reaction gas of the I layer is hydrogen, silane and germane , the thickness is about 200-300 nm; the reaction gas of the P layer is hydrogen, silane, borane, and the thickness is about 15-30 nm. The same ITO (indium tin oxide) film was deposited as the front electrode with a thickness of about 70 nm using the magnetron sputtering method (operating frequency 13.56 MHz).

[0018] The amorphous silicon germanium thin-film cells with the above structures all adopt a V-shaped tapered bandgap structure in the deposition process of the intrinsic layer. Ba...

Embodiment 2

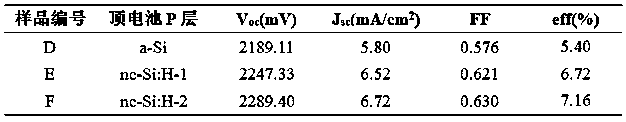

[0026] Three P-type layers with different preparation parameters were applied to the top cell of the triple-junction amorphous silicon germanium thin film cell (a-Si:H / a-SiGe:H / a-SiGe:H), and the I-V characteristics of the prepared cell were as follows Table 3 shows.

[0027] The P layer of the top cell of sample D adopts ordinary P-type layer conditions, and samples E and F adopt nc-Si:H-1 conditions and nc-Si:H-2 conditions respectively. The laws of the germanium series experiments are basically the same. With the continuous improvement of the p-layer conditions, the various I-V characteristic parameters of the battery have been optimized and improved.

[0028] Table 3 The performance of double-junction amorphous silicon germanium cells corresponding to the P layer of the top cell with different structures

[0029]

[0030] The above two examples show that this optimized new P-type layer is very suitable for use in the top cell of double-junction and triple-junction am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com