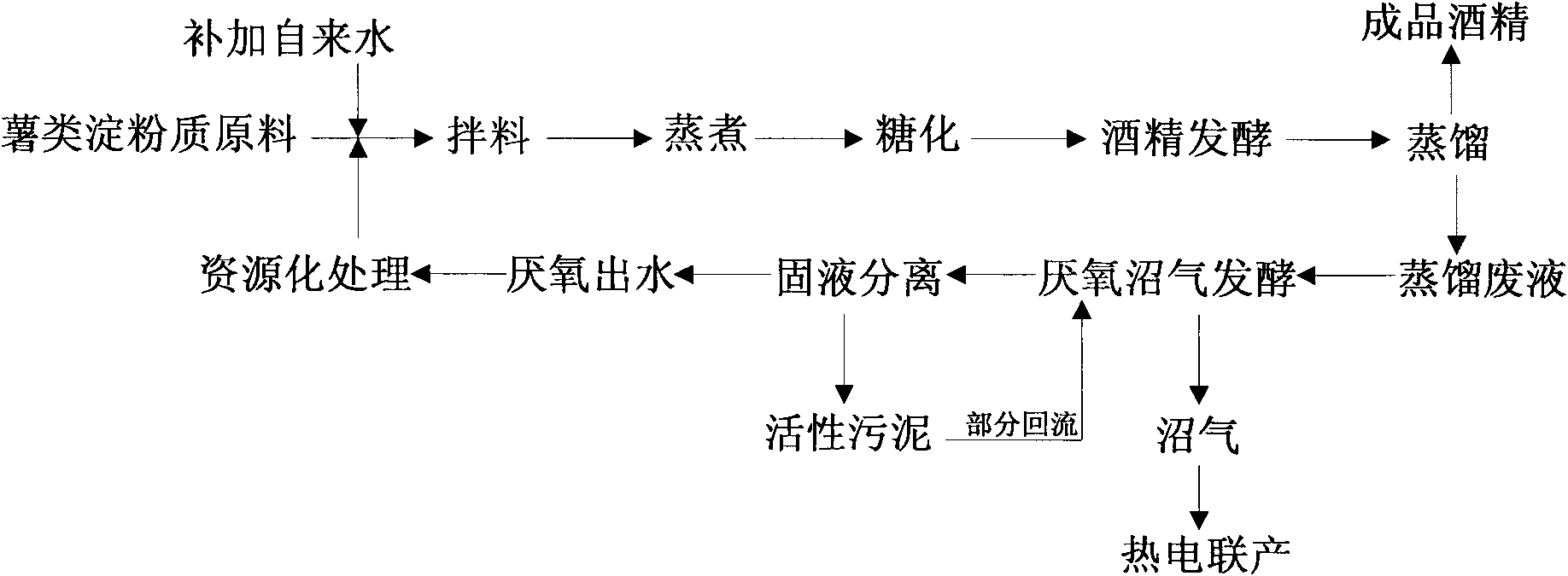

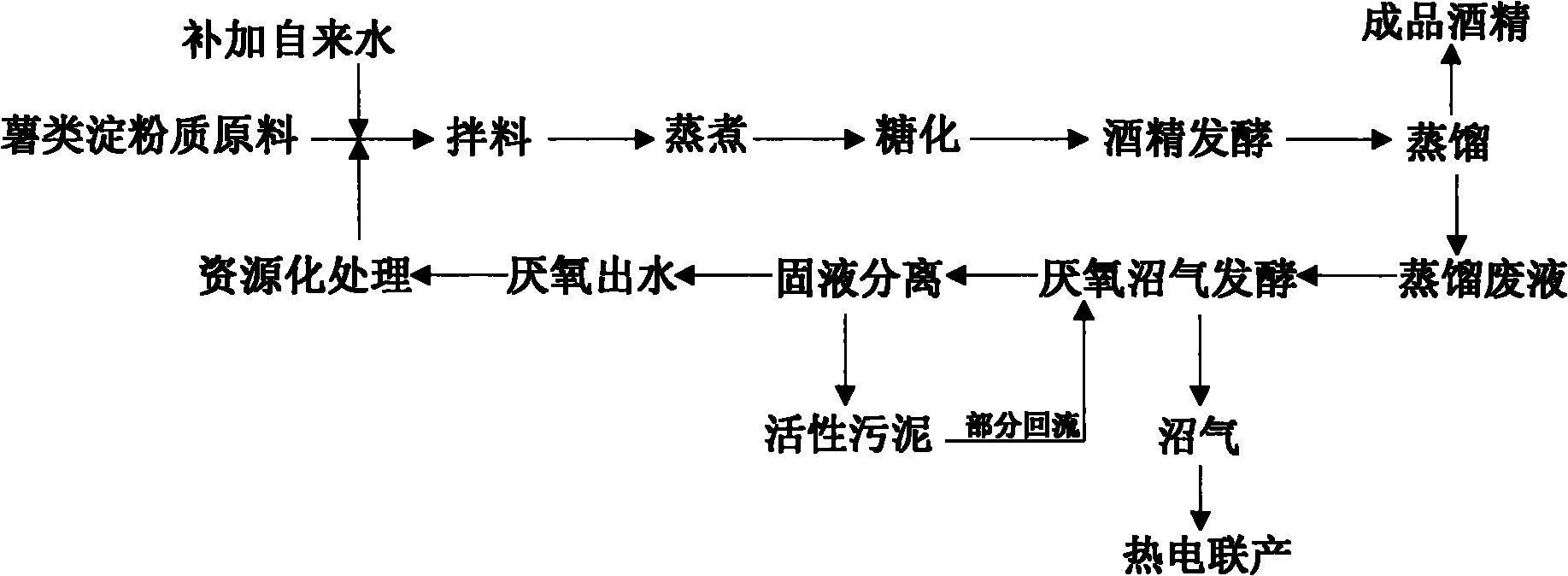

Method for producing alcohol by using anaerobic effluent in water recycling way

An anaerobic effluent and water resource technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can reduce the consumption of sulfuric acid, reduce the production cost and improve the alcohol content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0027] Embodiment two: a kind of method of anaerobic effluent water resource production alcohol, adopt following process step:

[0028] 1. For anaerobic biogas fermentation, the alcohol distillation waste liquid is cooled to 60°C and enters the first-stage high-temperature anaerobic UASB reactor. The temperature is maintained at 60°C, the hydraulic retention time (HRT) is 2 days, and the pH is 7.5-8.0. The first-stage high-temperature anaerobic effluent undergoes natural settlement and is cooled to 55°C at the same time. The settled sludge is returned to the high-temperature reactor, and the effluent enters the second-stage high-temperature UASB reactor. Maintain the temperature at 55°C, HRT at 4d, and pH at 7.8-8.2. The biogas generated by the first-stage high temperature and the second-stage high temperature are collected and entered into the cogeneration process;

[0029] 2. The second-stage high-temperature anaerobic effluent enters the oxidation treatment tank, maintai...

Embodiment 3

[0037] Embodiment three: a kind of method of anaerobic effluent water resource production alcohol, adopt following process step:

[0038] 1. For anaerobic biogas fermentation, the wine viscous distillation waste liquid is cooled to 60°C, and enters the first-stage high-temperature anaerobic UASB reactor. The temperature is maintained at 60°C, the hydraulic retention time (HRT) is 3 days, and the pH is 7.5-8.0. The first-stage high-temperature anaerobic effluent undergoes natural settlement and is cooled to 35°C at the same time. The settled sludge is returned to the high-temperature reactor, and the effluent enters the second-stage medium-temperature UASB reactor. Maintain the temperature at 35°C, HRT at 6d, and pH at 8.0-8.2. The biogas generated by the first-stage high temperature and the second-stage medium temperature are collected and entered into the cogeneration process;

[0039] 2. The second-stage mesothermal anaerobic effluent enters the oxidation treatment tank, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com