Process of producing 1,1 diaryl alkanes and derivatives thereof

A technology for diarylalkanes and aromatic compounds, applied in the field of manufacturing 1,1-diarylalkanes, can solve the problems of poor isomer selectivity, unsatisfactory reaction yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

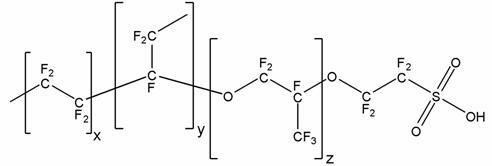

Image

Examples

Embodiment 1

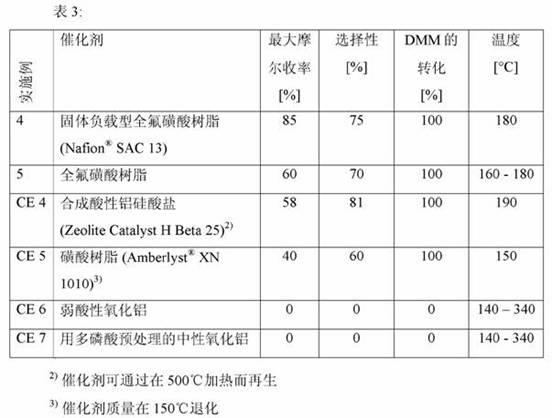

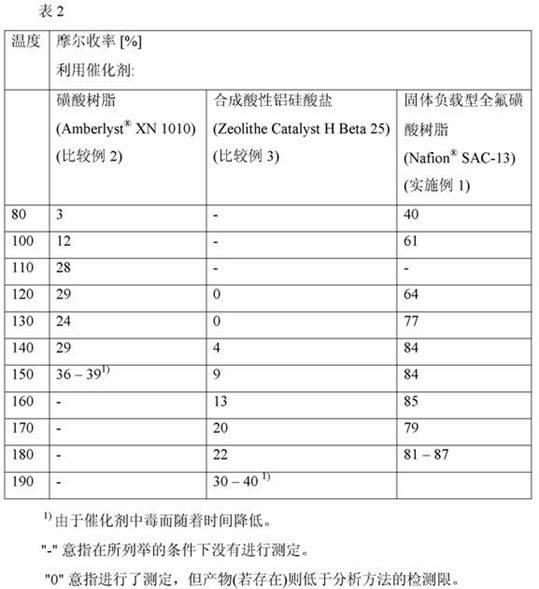

[0040] A tubular reactor (2.54 cm x 38.1 cm stainless steel) was filled with 18.01 grams of solid-supported perfluorosulfonic acid resin (Nafion® SAC-13). The catalyst bed was dried by heating to 150°C overnight under a nitrogen purge. The filled reactor was cooled to ambient temperature and a back pressure regulator set at 1379 kPa was attached to the outlet of the reactor. The system was primed with o-xylene at a flow rate of 0.89 mL / min and the reactor bed was heated to 170°C. Once the reactor bed was at temperature, the pure ortho-xylene feed was replaced with 6 wt% DMM in ortho-xylene and the flow rate was maintained at 0.89 mL / min. Analysis of the product stream leaving the tubular reactor showed that in 79 mol% yield, and with about 75% selection of the isomer 3,3',4,4'-tetramethyldiphenylmethane Proactively produces di(xylyl)methane (DXM).

Embodiment 2

[0042] The synthesis of DXM from DMM and o-xylene using solid-supported perfluorosulfonic acid resin (Nafion® SAC-13) was carried out using equipment similar to that described in Example 1.

[0043]A catalyst-packed tube reactor was prepared by heating at 150° C. overnight under a nitrogen purge. The tube reactor was cooled to room temperature. Turn on the pump and establish a flow of the DMM / o-xylene mixture at 1.0 mL / min. The tube furnace temperature was set at 40°C and the reactor temperature was increased by 15°C every 0.5-2.0 hours. An increase in the molar yield of DXM was observed with temperature up to 140 °C. DMM was detected in the product stream until the reaction temperature reached 180°C. For airspeed 2.9hr -1 (1.0 mL / min) and 6 wt% DMM concentration, the best molar yield (85%), selectivity (70-75%) and DMM conversion (100%) occurred at 180 °C.

Embodiment 3

[0045] The synthesis of DXM from DMM and o-xylene using perfluorosulfonic acid resin was carried out using equipment similar to that described in Example 1.

[0046] A catalyst-packed tube reactor was prepared by heating at 150° C. overnight under a nitrogen purge. The tube reactor was cooled to room temperature. Turn on the pump and establish a flow of the DMM / o-xylene mixture at 1.0 mL / min. The tube furnace temperature was set at 40°C and the reactor temperature was increased until the reaction temperature reached 160°, 170° or 180°C, then held at this temperature for a period of 8-10 hours while periodically sampling the product stream. Analysis showed a constant DXM molar yield of 60%. It is also observed that the isoselectivity is sustained at 70% in this range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com