High-temperature insulating gel for electric heating film heating pipe

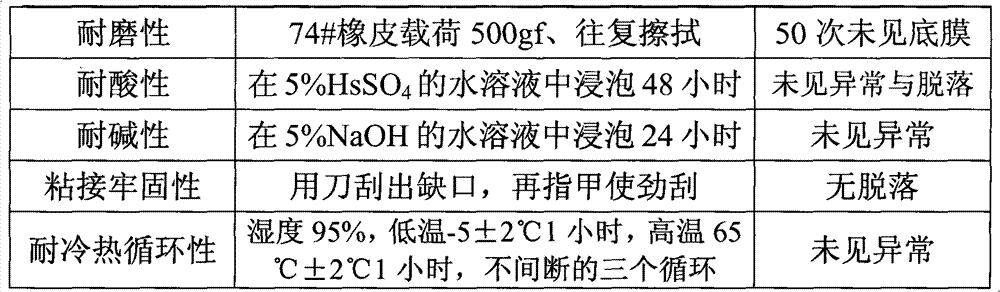

An electrothermal film heating tube and high-temperature insulation technology, which is applied in coatings, epoxy resin coatings, etc., can solve the problems of wear resistance, acid and alkali resistance, bonding firmness, and cold and heat cycle resistance. Excellent electrical insulation, small power attenuation, and good folding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1, the high-temperature insulating gel formula for electric heating film heating pipe, the weight percentage of each component in the formula is 26% of epoxy resin, 10% of epoxy resin insulating coating, 11% of ether ester solvent, and 9% of ketone solvent %, ester solvent 20%, alcohol ether solvent 8%, shrinkage oil ether diluent 16%. The glycidyl ether diluent is polyethylene glycol diglycidyl ether. The ether ester solvent is propylene glycol methyl ether acetate, the ketone solvent is acetone, the ester solvent is methyl acetate, and the alcohol ether solvent is ethylene glycol monomethyl ether. Epoxy resin insulating coating can adopt the products of Qingdao Dazhou Electronic Materials Co., Ltd.

Embodiment 2

[0040] Example 2, the high-temperature insulating gel formula for electric heating film heating pipe, the weight percentage of each component in the formula is 25% of epoxy resin, 15% of epoxy resin insulating coating, 15% of ether ester solvent, 6% of ketone solvent %, ester solvent 15%, alcohol ether solvent 10%, shrinkage oil ether diluent 14%. The glycidyl ether diluent is lauryl glycidyl ether. The ether ester solvent is epoxy ether propionate, the ketone solvent is methyl butanone, the ester solvent is ethyl acetate, and the alcohol ether solvent is ethylene glycol monoethyl ether.

Embodiment 3

[0041] Example 3, high-temperature insulating gel formula for electric heating film heating tube, the weight percentage of each component in the formula is 30% of epoxy resin, 5% of epoxy resin insulating coating, 13% of ether ester solvent, 12% of ketone solvent %, 25% of ester solvents, 5% of alcohol ether solvents, and 10% of shrinkage oil ether diluents. The glycidyl ether diluent is cresol glycidyl ether. The ether ester solvent is ethylene glycol butyl ether acetate, the ketone solvent is methyl isobutyl ketone, the ester solvent is propyl acetate, and the alcohol ether solvent is ethylene glycol monobutyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com