Method for measuring reflectivity of dual-wavelength high reflecting mirror

A technology of high reflection mirror and measurement method, which is applied in the direction of testing optical performance, etc., and can solve the problems of device adjustment difficulty, reduction of output signal amplitude of optical cavity, and decrease of signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

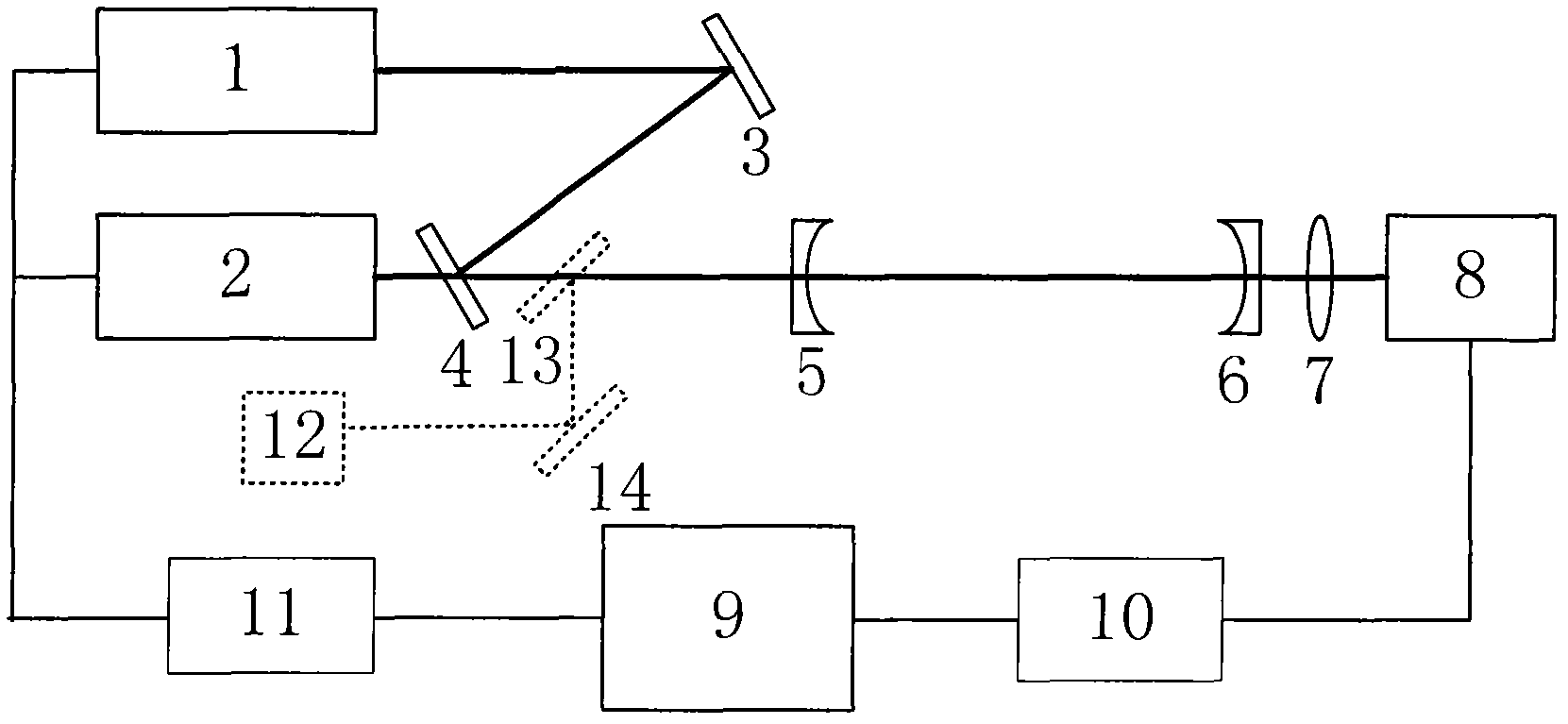

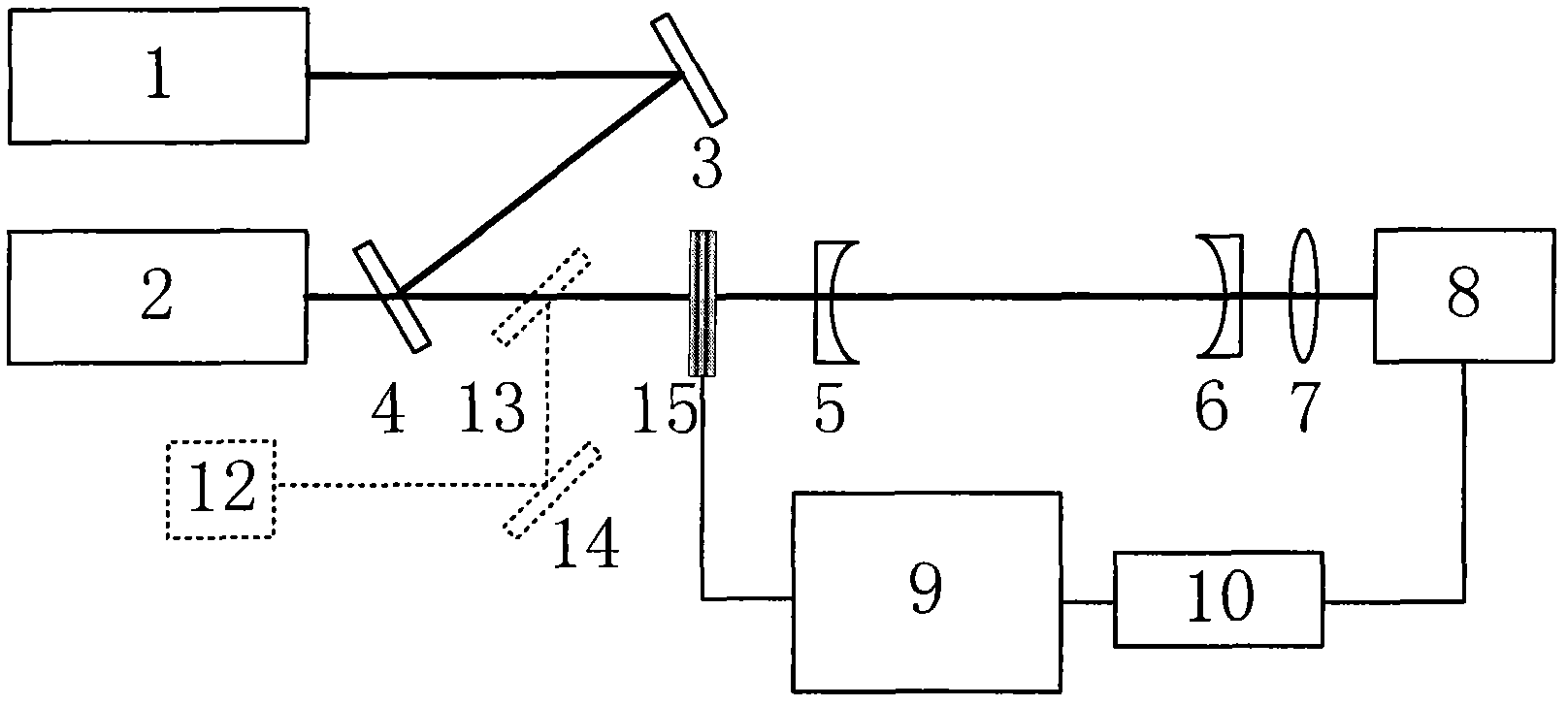

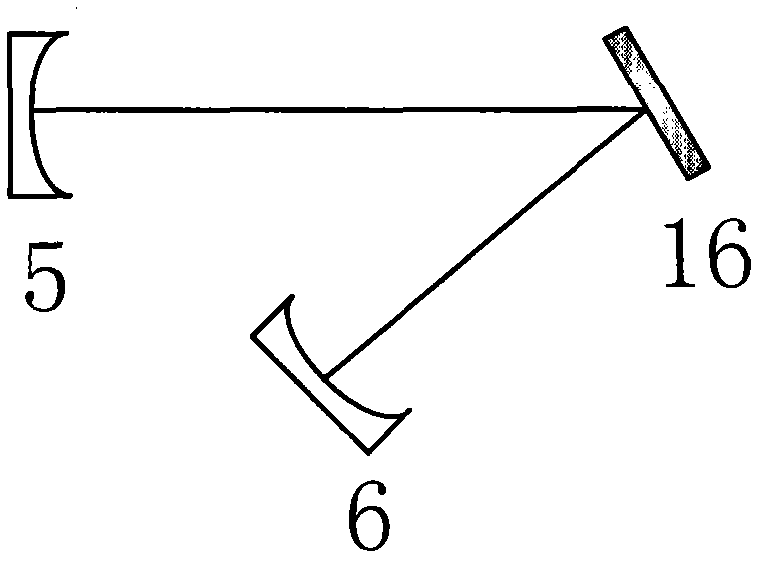

[0037] Attached below figure 1 The measurement system describes the method for measuring the reflectivity of the dual-wavelength high-reflector of the present invention. figure 1 Middle: 1, 2 are laser light sources with two different wavelengths, 3 is a reflector, 4 is a double-beam beam splitter, 5 and 6 are plano-concave dual-wavelength high-reflection mirrors, 7 is a focusing lens, 8 is a photodetector, 9 is a computer, 10 is a data acquisition card, 11 is a function generation card, 12 is a visible auxiliary alignment light source, 13 is a beam splitter, and 14 is a reflector. The thick line in the figure is the optical path, and the thin line is the connection line.

[0038] Both light sources 1 and 2 are continuous semiconductor lasers, and the two semiconductor lasers are output by square wave modulation; the two laser beams are combined through the mirror 3 and the double beam splitter 4, so that they are injected into the ring-down cavity at the same time; two plano-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com