Laminated organic light emitting diode and preparation method thereof

A light-emitting diode and organic technology, applied in organic chemistry, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as increased brightness and current efficiency, increased voltage, and no improvement in the power efficiency of stacked organic light-emitting diodes. Increased brightness and current efficiency, reduced operating voltage, and improved power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

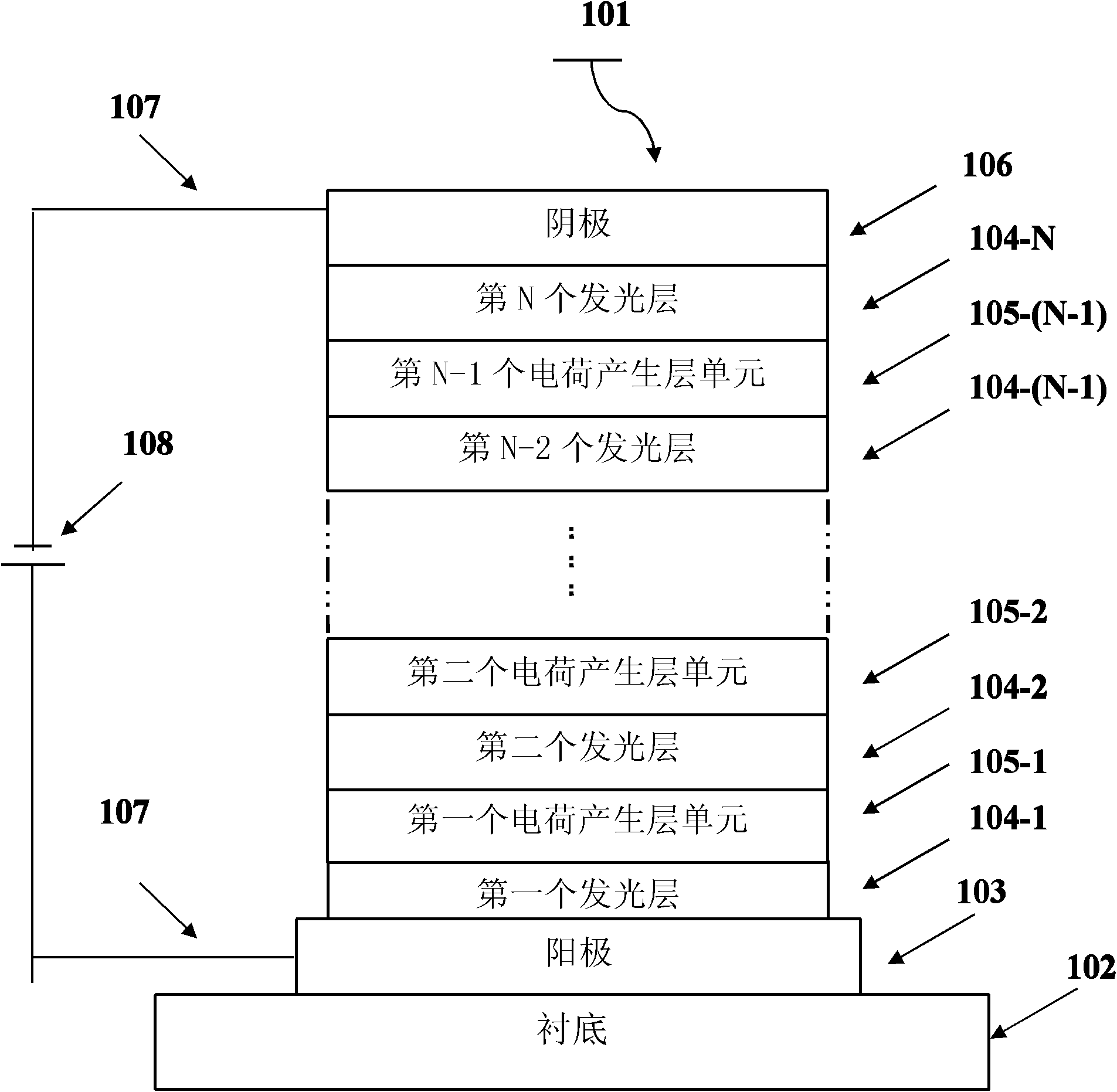

[0042] The invention also discloses a method for preparing a laminated organic light emitting diode, comprising:

[0043] evaporating at least two light-emitting layers between the anode and the cathode;

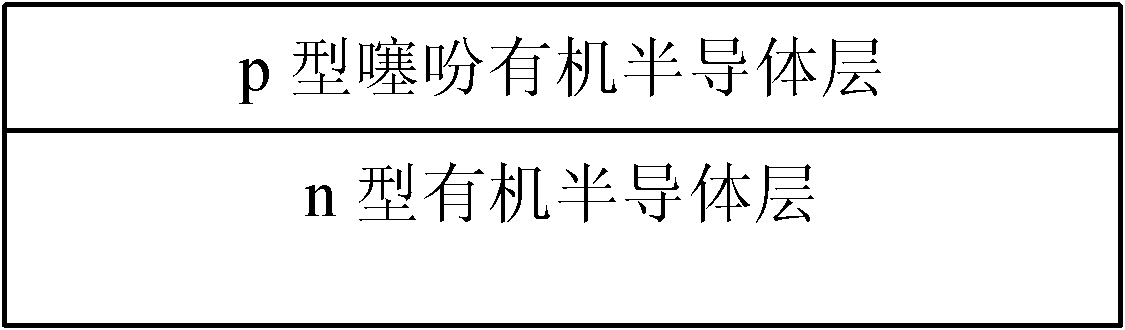

[0044] A charge generation layer is vapor-deposited between adjacent light-emitting layers, the charge generation layer is a heterojunction formed by an n-type organic semiconductor and a p-type organic semiconductor, the p-type organic semiconductor is a thiophene compound, and the p-type organic semiconductor The highest occupied molecular orbital energy level of the semiconductor is less than 6eV, and the difference between the highest occupied molecular orbital energy level of the p-type organic semiconductor and the lowest unoccupied molecular orbital energy level of the n-type organic semiconductor is less than 1eV.

[0045] The substrate is preferably a glass substrate or a flexible substrate, and the flexible substrate is preferably a polycarbonate flexible substrate...

Embodiment 1

[0053] The anode layer ITO on the ITO glass is photolithographically formed into thin strip electrodes, then cleaned, dried with nitrogen, treated with oxygen plasma for 2 minutes, and then transferred to the vacuum coating system;

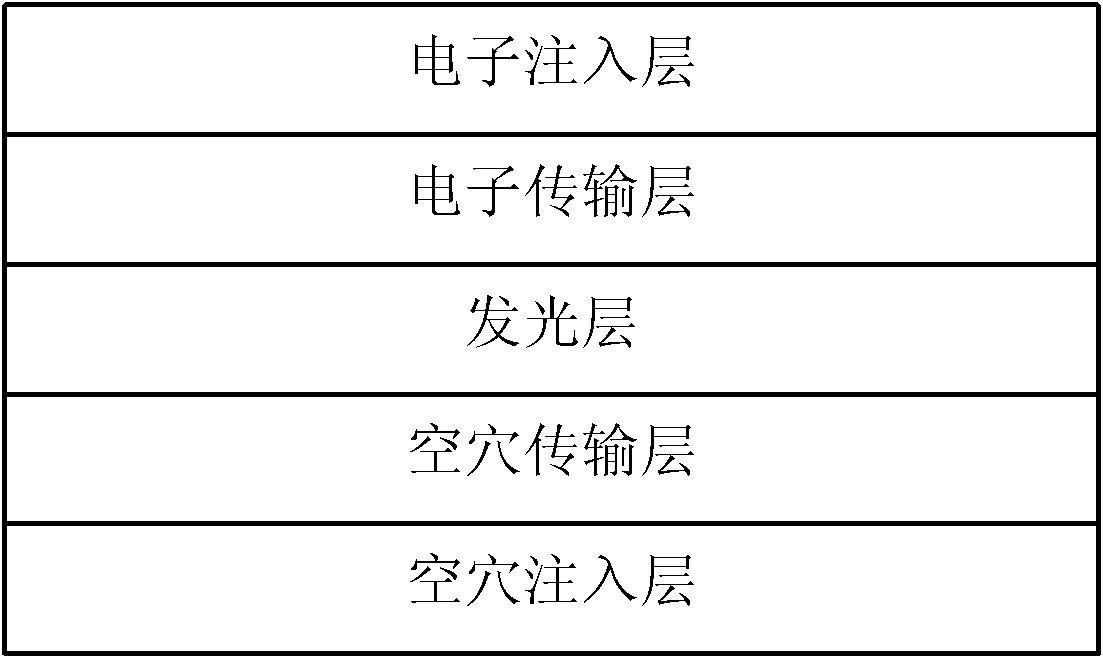

[0054] Wait until the vacuum degree in the vacuum coating system reaches 5×10 -4 4.5 nm MoO was sequentially deposited on the ITO electrode 3 Hole injection layer, 90nm NPB hole transport layer, 30nm C545T doped in Alq 3 Light-emitting layer composed of medium, 30nm Alq 3 Electron transport layer, 1nm LiF electron injection layer, 20nm C 60 n-type organic semiconductor, 10nm NaT3p-type organic semiconductor, 3nm MoO 3 Hole injection layer, 50nm NPB hole transport layer, 30nm C545T doped in Alq 3 Light-emitting layer composed of medium, 30nm Alq 3 An electron transport layer, an electron injection layer of 1 nanometer LiF, and a metal cathode Al of 120 nanometers, wherein the positive and negative electrodes intersect each other to form a ligh...

Embodiment 2

[0057] The anode layer ITO on the ITO glass is photolithographically formed into thin strip electrodes, then cleaned, dried with nitrogen, treated with oxygen plasma for 2 minutes, and then transferred to the vacuum coating system;

[0058] Wait until the vacuum degree in the vacuum coating system reaches 5×10 -4 4.5 nm MoO was sequentially deposited on the ITO electrode 3 Hole injection layer, 120nm NPB hole transport layer, 30nm C545T doped in Alq 3 Light-emitting layer composed of medium, 30nm Alq 3 Electron transport layer, 1nm LiF electron injection layer, 20nm C 60 n-type organic semiconductor, 10nm TNT2p-type organic semiconductor, 3nm MoO 3 Hole injection layer, 50nm NPB hole transport layer, 30nm C545T doped in Alq 3 Light-emitting layer composed of medium, 30nm Alq 3 An electron transport layer, an electron injection layer of 1 nanometer LiF, and a metal cathode Al of 120 nanometers, wherein the intersecting parts of the positive and negative electrodes form a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com