Method for preparing sodium bisulfate/attapulgite clay composite solid acid catalyst

A technology of attapulgite clay and composite solid acid, which is applied in the preparation of carboxylic acid/symmetric anhydride and saturated hydrocarbon, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc. Site reduction and other problems, to achieve the effect of increasing added value, reducing catalyst dosage, and avoiding coating and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

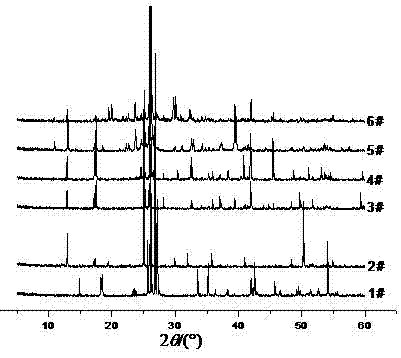

Image

Examples

Embodiment 1

[0022] Example 1: First, prepare 0.2 mol L -1 sodium bisulfate solution; secondly, 20.0 g of attapulgite clay and 416.8 mL of 0.2 mol·L -1 The sodium bisulfate solution was intermittently added to a cylindrical glass container at a temperature of 15 °C, and then soaked for 30 min after the addition; finally, the mixture was introduced into a desiccator from the bottom of the container, directly stirred and heated until the mixture was dry, and then cooled to room temperature , to obtain sodium bisulfate / attapulgite clay composite solid acid catalyst.

Embodiment 2

[0023] Example 2: First, prepare 0.5 mol L -1 of sodium bisulfate solution; secondly, 20.0 g of attapulgite clay and 333.4 mL of 0.5 mol·L -1 The sodium bisulfate solution was intermittently added to a cylindrical glass container at a temperature of 20 °C, and then soaked for 60 min after the addition; finally, the mixture was suction-filtered from the bottom of the container, then stirred and heated until the mixture was dry, cooled to room temperature, and obtained Sodium bisulfate / attapulgite clay composite solid acid catalyst.

Embodiment 3

[0024] Example 3: First, prepare 1.0 mol L -1 of sodium bisulfate solution; secondly, 20.0 g of attapulgite clay and 250.0 mL of 1.0 mol·L -1 The sodium bisulfate solution was intermittently added to a cylindrical glass container at a temperature of 30°C, and then soaked for 90 min after the addition; finally, the mixture was introduced into a desiccator from the bottom of the container, stirred and heated until the mixture was dry, and then cooled to room temperature , to obtain sodium bisulfate / attapulgite clay composite solid acid catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com