Mutual non-solid-solution system metal infiltration process and device based ion implantation radiation damage

A technology of mutual insolubility and radiation damage, which is applied in the field of metal surface processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is described in detail in conjunction with the embodiments and the accompanying drawings.

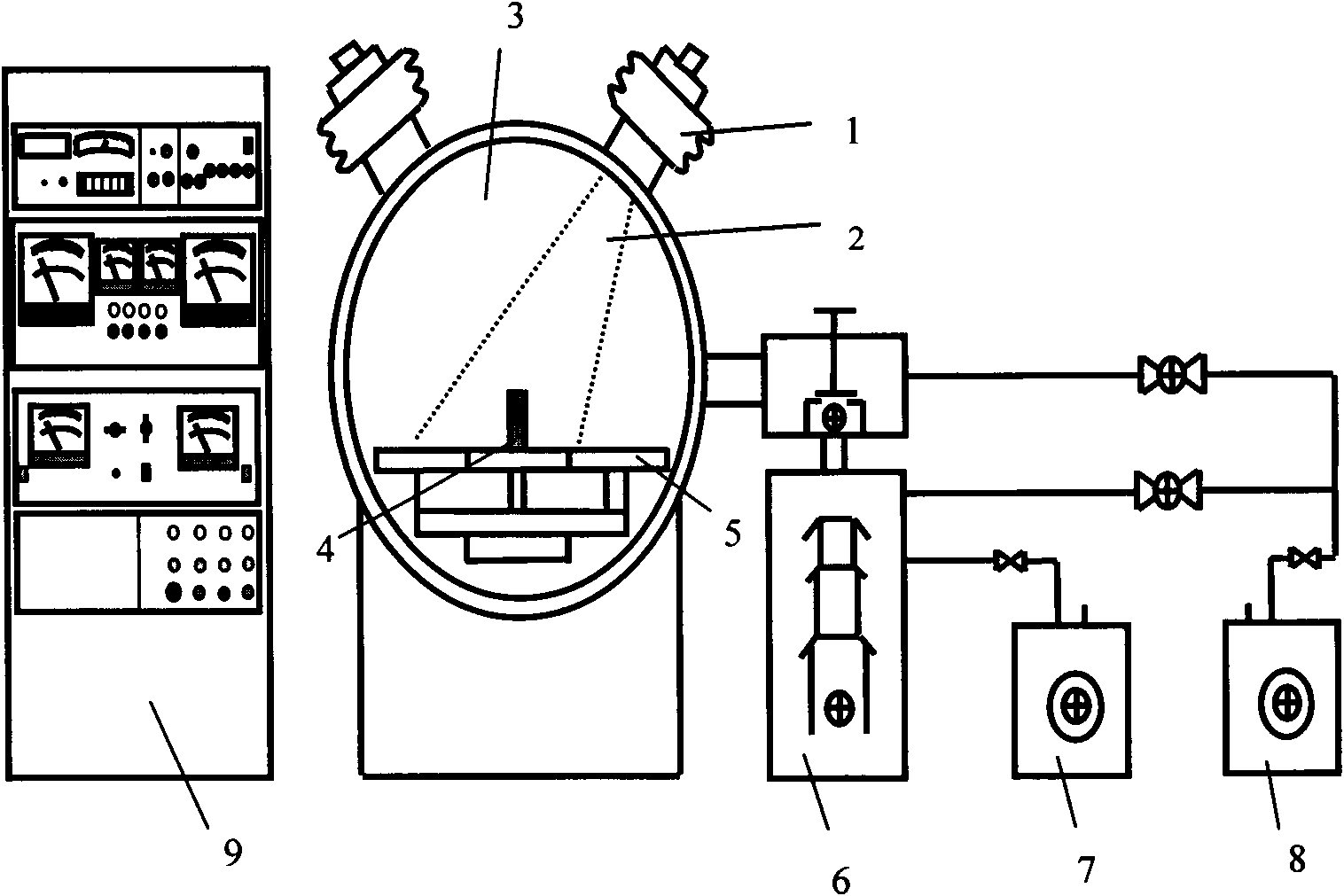

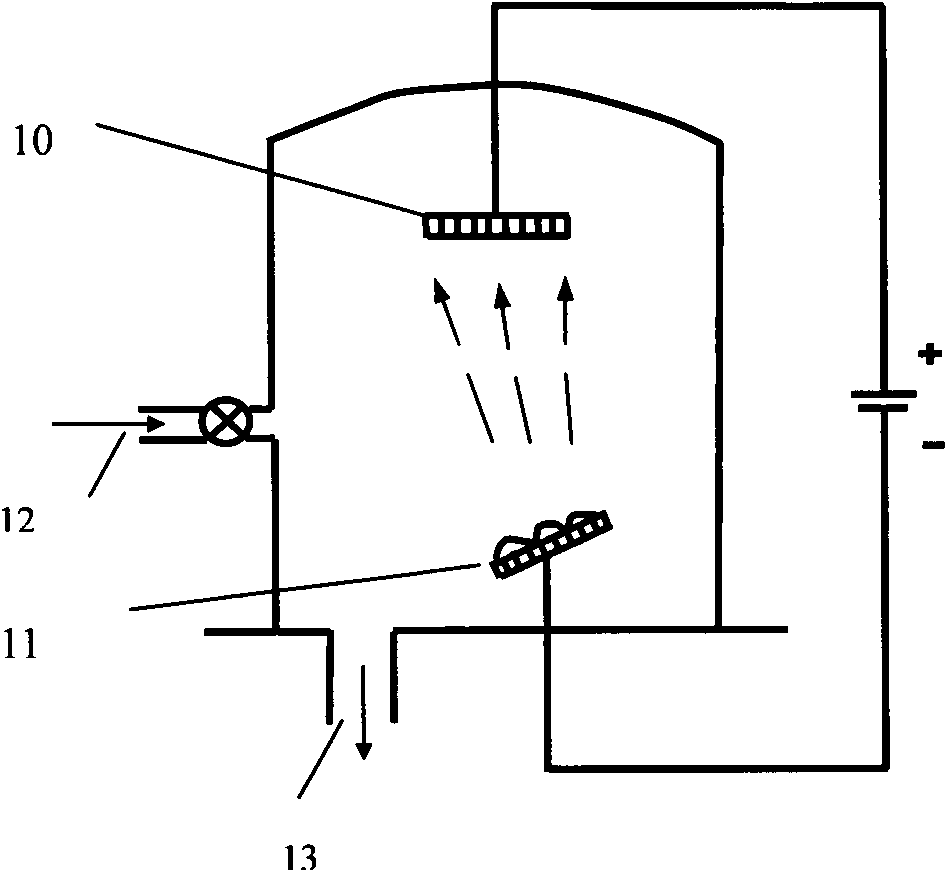

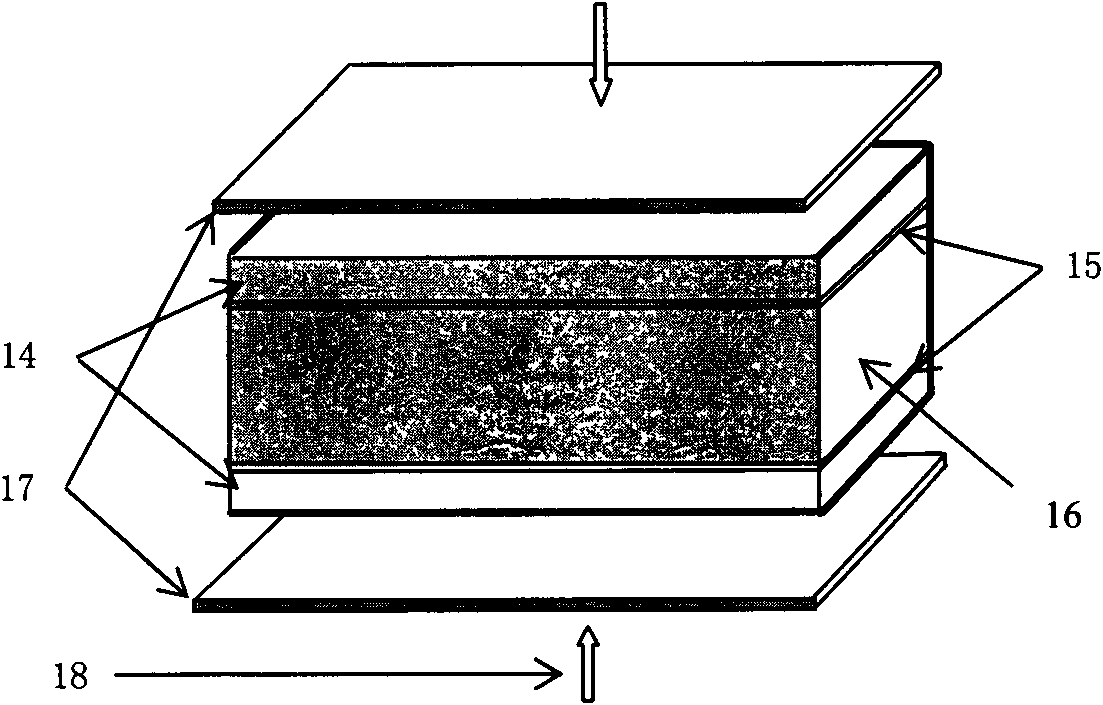

[0058] figure 1 It is a schematic diagram of silver ion implantation tungsten metal device, in which, 1-ion source, 2-ion beam, 3-implantation chamber, 4-tungsten metal sample, 5-target disc, 6-vacuum diffusion pump, 7-maintenance pump, 8- Mechanical pump, 9-high pressure and system control cabinet. The components of the ion implanter include ion source, vacuum implantation chamber, target plate, vacuum system, high voltage and control cabinet. Among them, the vacuum system is composed of a diffusion pump, a maintenance pump and a mechanical pump. The vacuum system is directly connected to the vacuum injection chamber through a valve; the target disk is located in the injection chamber; the ion source is located above the injection chamber and is obliquely opposite to the target disk. During implantation, the ion source is supplied with arc voltage, trigge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com