Preparation method for halogen-free flame-retardant polypropylene fibers

A flame-retardant polypropylene and polypropylene chip technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyolefin rayon, chemical post-processing of synthetic polymer rayon, etc. Material cost, influence on flame retardant performance and other issues, to achieve a wide range of applications, reduce production costs, and good flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

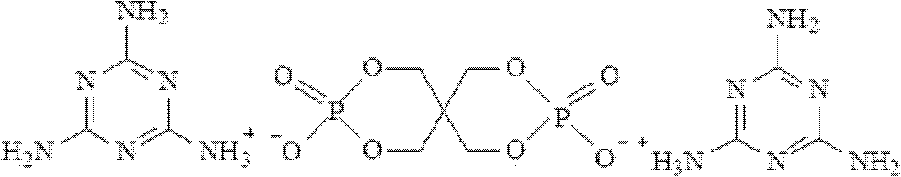

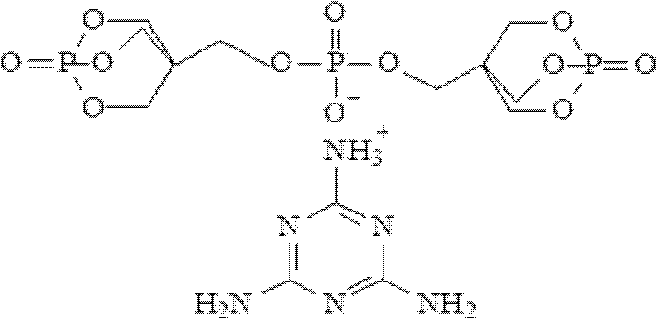

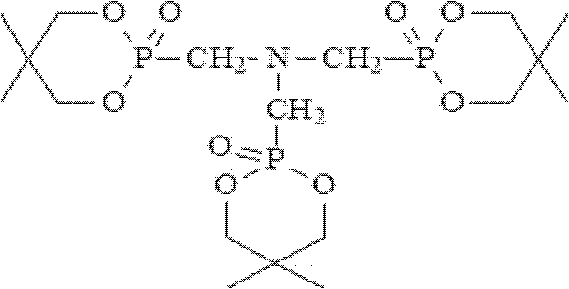

[0035] Cut 55 kg of PP, 35 kg of compound intumescent flame retardant (ammonium polyphosphate: pentaerythritol: melamine = 6:1: 3), 8.5 kg of EVA, 1.48 kg of antioxidant 1010, 0.02 kg of hydroxyphenyl benzotriazole The azole ultraviolet absorber is uniformly mixed and then mixed and granulated by a twin-screw extruder at a temperature of 210-230° C. to obtain a PP expansion flame-retardant master batch. Blend 100kg flame-retardant masterbatch with 700kg PP chips, the screw temperature is controlled at 195~230℃, the metering pump specification is 0.6ml / r, the metering pump revolution is 10r / min, the spinneret hole diameter is 0.6mm, the number of holes is 16, The spinning speed is 133m / min, the winding speed is 300m / min, and the tow is heated for 4 times after winding to obtain flame-retardant PP raw yarn. The original filaments are bundled and formed into tow sheets with a thickness of 1mm, which are continuously fed into low-energy electron beam irradiation equipment for conti...

Embodiment 2

[0037] Cut 60 kg of PP, 33 kg of compound intumescent flame retardant (triphenyl phosphate: neopentyl glycol: melamine = 8: 0.5: 1.5), 6 kg of PP wax, 0.98 kg of composite antioxidant 215, 0.02 kg The hydroxyphenyl benzotriazole ultraviolet absorber is uniformly mixed and then mixed and granulated through a twin-screw extruder at a temperature of 210-230° C. to obtain a PP expansion flame-retardant master batch. Blend 100kg flame-retardant masterbatch with 300kg PP chips, the screw temperature is controlled at 195~230℃, the metering pump specification is 0.6ml / r, the metering pump revolution is 10r / min, the spinneret hole diameter is 0.6mm, and the number of holes is 16. The spinning speed is 133m / min, the winding speed is 300m / min, and the tow is heated for 4 times after winding to obtain flame-retardant PP raw yarn. The original filaments are bundled into a tow sheet with a thickness of 1mm, which is continuously fed into a low-energy electron beam irradiation equipment for c...

Embodiment 3

[0039] Cut 50 kg of PP, 40 kg of compound intumescent flame retardant (melamine polyphosphate: pentaerythritol: melamine = 7:1: 2), 8.6 kg of PP wax, 1.38 kg of composite antioxidant 225, 0.02 kg of hydroxyphenylbenzene The triazole ultraviolet absorber is uniformly mixed and then mixed and granulated by a twin-screw extruder at a temperature of 210-230° C. to obtain a PP expanded flame-retardant master batch. Blend 100kg flame-retardant masterbatch with 800kg PP chips, the screw temperature is controlled at 195~230℃, the metering pump specification is 0.6ml / r, the metering pump revolution is 10r / min, the spinneret hole diameter is 0.8mm, the number of holes is 8. The spinning speed is 149m / min, the winding speed is 400m / min, and the tow is subjected to 3 times hot drawing after winding to obtain flame-retardant PP raw yarn. The original filaments are bundled into a tow sheet with a thickness of 1mm, which is continuously fed into a low-energy electron beam irradiation equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com