Lead-free solder for hot dipping of solar battery and preparation method thereof

A solar cell, lead-free solder technology, applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of decreased product competitiveness and increased solder production costs, to improve utilization and improve surface quality. , the effect of good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

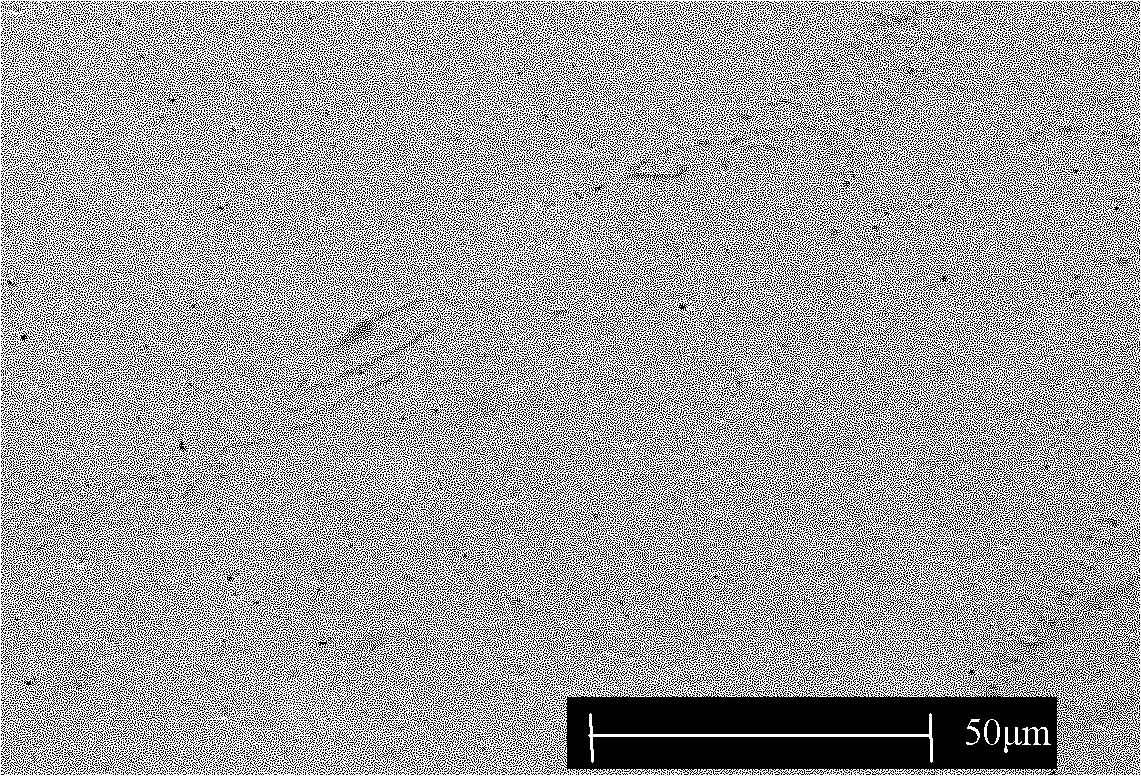

[0019] Heat tin, bismuth and antimony with a purity of 99.99% in a mass ratio of 98.9:1.0:0.1 in a vacuum melting furnace under the protection of argon to 800°C for melting, and at the same time add magnetic stirring to make the alloy composition uniform, and then condense and solidify . Then the alloy is turned over and reheated to 500° C. to melt, and at the same time, it is magnetically stirred and water-cooled, so that the Sn-1%Bi-0.1%Sb lead-free solder is obtained by repeating this at least four times. Its microstructure is as figure 1 As shown, the matrix is in the β-Sn phase, and the particles are in the SnSb phase. This alloy has high electrical conductivity, fine structure, good ductility, and a melting point of about 206°C.

example 2

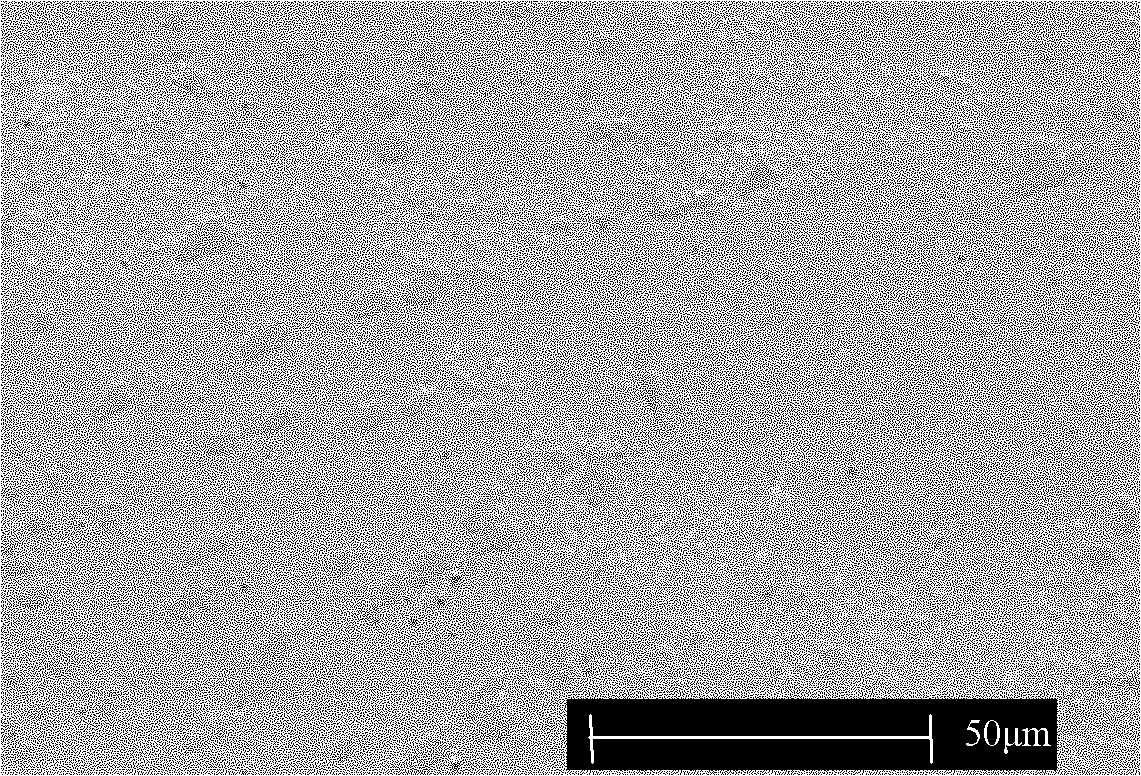

[0021] Heat tin, bismuth and antimony with a purity of 99.99% in a mass ratio of 93.5:4:2.5 in a vacuum melting furnace under the protection of argon to 800°C for melting, and at the same time add magnetic stirring to make the alloy composition uniform, and then water-cool and solidify . Then the alloy is turned over and reheated to 500° C. to melt, and at the same time, it is magnetically stirred and water-cooled, so that the Sn-4%Bi-2.5%Sb lead solder is obtained by repeating this for at least four times. Its microstructure is as figure 2 As shown, the matrix is β-Sn phase, the particles are SnSb phase, and the white particles are Bi particles. The alloy has a lower melting point, higher microhardness and tensile strength. The addition of Bi reduces the melting point of the alloy to about 190°C, which has excellent wettability, and Sb makes the alloy have better tensile properties.

example 3

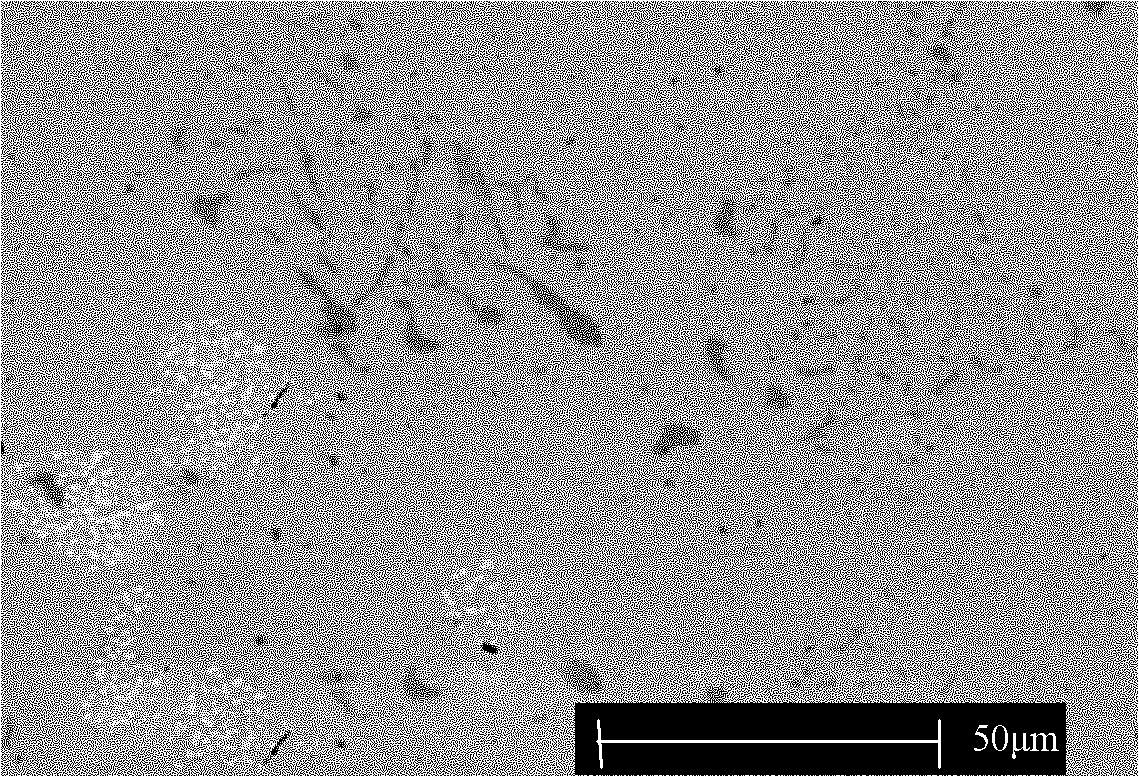

[0023] The tin, bismuth, antimony, and silver with a purity of 99.99% are heated to 800°C in a vacuum melting furnace under the protection of argon in a mass ratio of 96.5:2:1.5, and are magnetically stirred at the same time to make the alloy composition uniform, and then The water freezes. Then the alloy is turned over and reheated to 500° C. to melt, and at the same time, it is magnetically stirred and water-cooled, so that the Sn-2%Bi-1.5%Sb lead-free solder is obtained by repeating this at least four times. Its microstructure is as image 3 As shown, the dark gray particles are the SnSb phase, and the white enriched regions are Bi. This alloy has moderate wettability, superior tensile properties, good ductility, and high electrical conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com