Synergy method of surface plasmon metallic nano-chain in solar battery

A surface plasmon and solar cell technology, applied in the field of solar cells, can solve the problems of low sunlight absorption efficiency and low light absorption efficiency, and achieve the effects of improving absorption efficiency, improving photoelectric conversion efficiency, and increasing effective transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

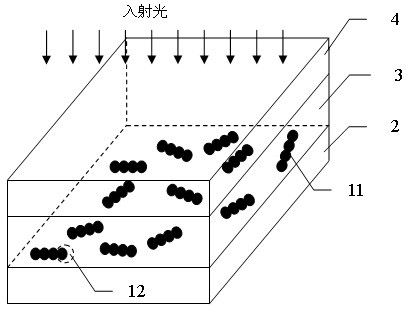

[0022] The preparation method of the metal nanochain 11 includes a variety of physical and chemical methods, including, firstly, the colloidal solution of the metal nanoparticle 12 is prepared by a chemical synthesis method, and then by a chemical self-assembly method or a chemical anisotropic etching method or a chemical welding method or The metal nanoparticles 12 in the colloidal solution are welded into metal nanochains 11 by laser irradiation welding method or heating welding method, etc. Then deposit the metal nanochains 11 in the sol solution on the surface of the back electrode 2 of the solar cell by a deposition method, a chemical self-assembly method or a drop coating method, and let the solvent volatilize naturally. Alternatively, a metal film with a thickness of several nanometers to hundreds of nanometers is coated on the surface of the back electrode 2 of the solar cell by sputtering coating method or thermal evaporation coating or other metal coating methods, and...

Embodiment 1

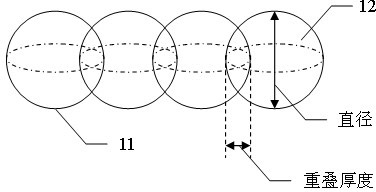

[0028] Embodiment 1: Prepare metal nanoparticles 12 as spherical metal nanochains 11 on the surface of the back electrode 2 of the solar cell. The metal nanosilver particle solution is prepared by a chemical synthesis method, and the diameter of the metal particles is about tens of nanometers to hundreds of nanometers. Femtosecond laser welding technology is used to irradiate the metal nano-silver particle solution, and the metal nano-silver particles are welded into metal silver nano-chains, and the number of metal nanoparticles contained in each nano-chain is not limited. The metallic silver particles overlap each other, and the overlapping thickness is about several nanometers. After welding, the surface of the back electrode 2 is coated with a configuration solution containing metallic silver nanochains, and then the solution is evaporated. Then, according to the standard solar cell preparation process, structures such as the photovoltaic layer 3 and the photoanode 4 are p...

Embodiment 2

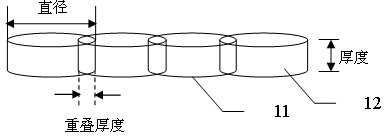

[0029] Embodiment 2: prepare metal nanoparticles 12 on the surface of the back electrode 2 of the solar cell to be disc-shaped metal nanochains 11, clean and dry the prepared solar cell back electrode 2 substrates, and use magnetron sputtering, thermal evaporation Plating and other coating processes deposit a layer of metallic silver film with a thickness ranging from tens of nanometers to hundreds of nanometers. The silver nanochain structure is prepared by electron beam etching, and the excess metal film is removed. In this way, an array of metal silver nanochains 11 with uniform shape and orderly arrangement direction can be prepared. Then, according to the standard solar cell preparation process, structures such as the photovoltaic layer 3 and the photoanode 4 are prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com