Non-contact type high-power energy transmission system and application

A non-contact, energy transmission technology, applied in electromagnetic wave systems, electrical components, circuit devices, etc., can solve problems such as power loss, high standby power consumption, system resonance frequency changes, etc., to avoid personal injury and improve energy utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

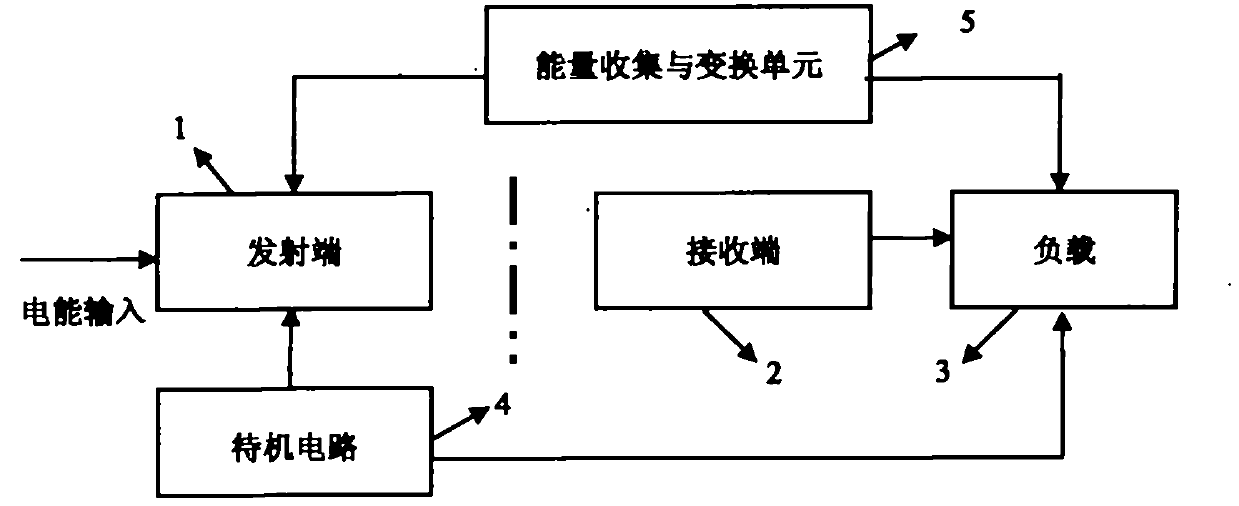

[0037] figure 1 It is a block diagram of the non-contact energy transmission system of the present invention, including five parts including a transmitter 1 , a receiver 2 , a load 3 , a standby circuit 4 , and an energy collection and conversion unit 5 . The transmitting end 1 generates a high-frequency current and provides it to the load power supply of the secondary loop through space magnetic field coupling. The standby circuit 4 controls the input of the power supply of the main circuit through the relay, and can detect whether the load exists in real time, and automatically start or shut down the power supply of the main circuit accordingly. The energy collection and conversion unit 5 collects, converts or heats the energy generated in the system to the primary side or the secondary side, so that the lost energy can be reused and energy loss is reduced.

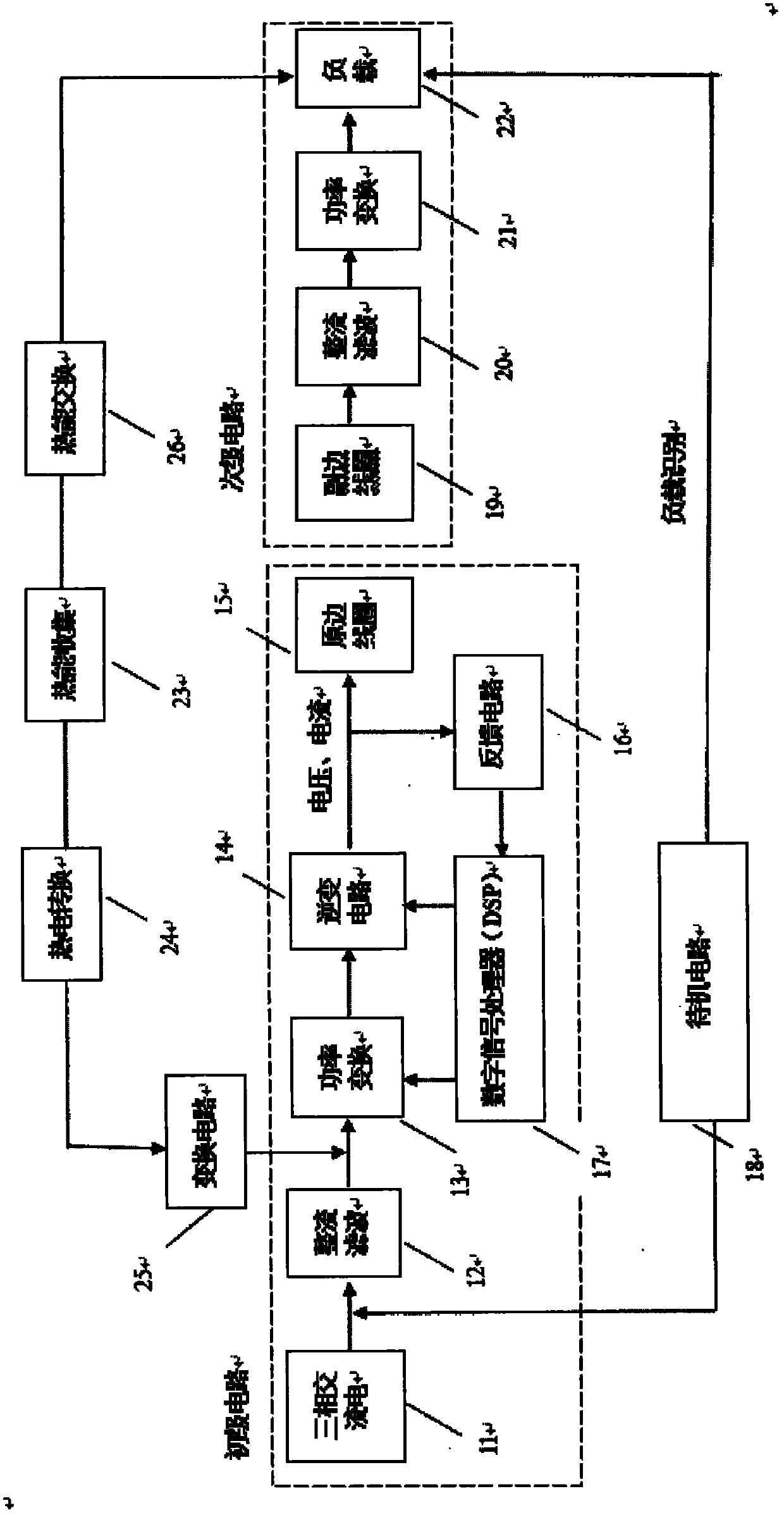

[0038] figure 2 Composition structure diagram for the contactless energy transfer system. The transmitting end in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com