Method for preparing powdery porous manganese dioxide electrode

A manganese dioxide electrode, electrolytic manganese dioxide technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of low wastewater treatment efficiency and unstable electrode performance, and achieve easy implementation and improved catalytic activity. , the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The first step, the preparation of electrolytic manganese dioxide:

[0017] The electrolyte is manganese sulfate solution, the mass concentration of manganese sulfate is 135g / L, the pH value is 3.9, the temperature of the electrolyte is 90°C, the titanium alloy is used as the anode, the carbon electrode is used as the cathode, and the current density is 10mA / cm 2 , The deposit obtained from the anode is washed, neutralized, ground and dried to obtain electrolytic manganese dioxide.

[0018] The second step, the preparation of powder porous manganese dioxide electrode:

[0019] Dry mix electrolytic manganese dioxide and expanded graphite evenly, the mass ratio of the two is 80:20, then add the binder (sodium carboxymethyl cellulose aqueous solution) drop by drop, stir until a paste-like object is formed, and the paste The body is smeared on both sides of a 3cm×3cm titanium mesh, compacted and dried to obtain a powdery porous manganese dioxide electrode.

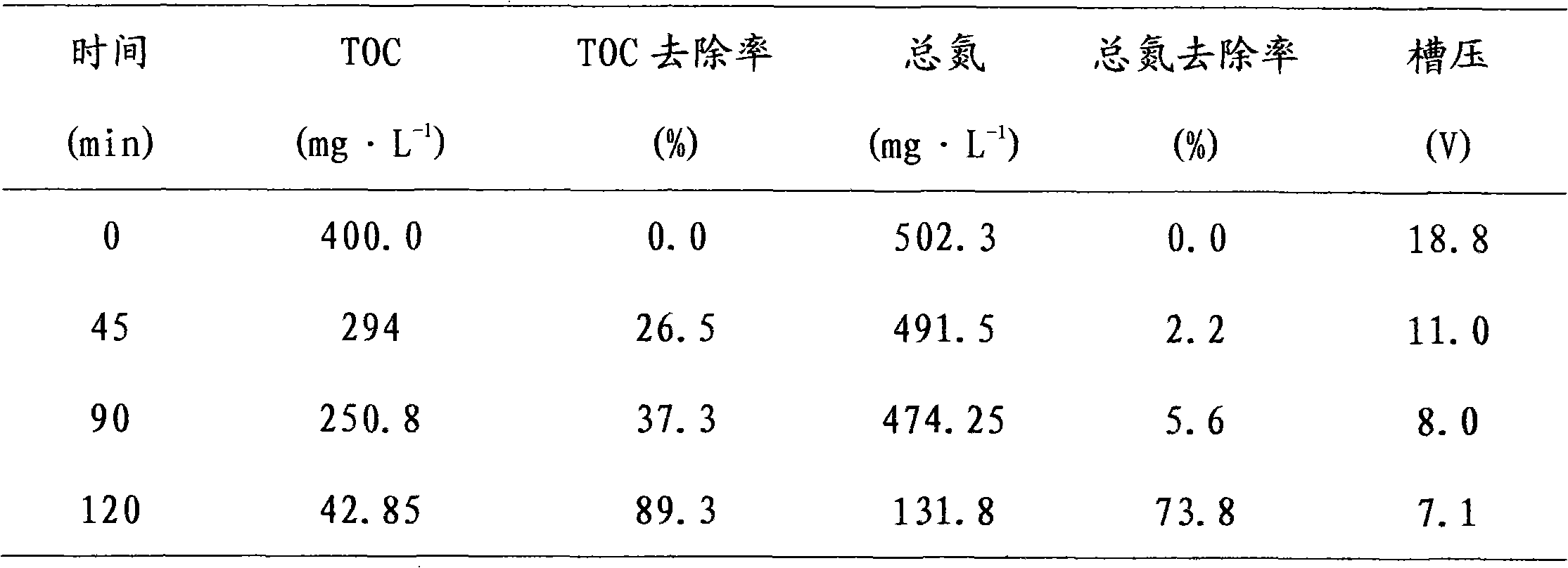

[0020] Test o...

Embodiment 2

[0026] The first step, the preparation of electrolytic manganese dioxide:

[0027] The electrolyte is manganese sulfate solution, the mass concentration of manganese sulfate is 130g / L, the pH value is 3.5, the temperature of the electrolyte is 90°C, the titanium alloy is used as the anode, the carbon electrode is used as the cathode, and the current density is 8mA / cm 2 , The deposit obtained from the anode is washed, neutralized, ground and dried to obtain electrolytic manganese dioxide.

[0028] The second step, the preparation of powder porous manganese dioxide electrode:

[0029] Dry mix electrolytic manganese dioxide and expanded graphite evenly, the mass ratio of the two is 90:10, then add the binder (sodium carboxymethyl cellulose aqueous solution) drop by drop, stir until a paste-like object is formed, and the paste The body is smeared on both sides of a 3cm×3cm titanium mesh, compacted and dried to obtain a powdery porous manganese dioxide electrode.

[0030] The pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ph | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com