High quality strain Ge/SiGe super-lattice structure and preparation method thereof

A technology of superlattice and superlattice layer, applied in the structure of active area, chemical instruments and methods, single crystal growth, etc., can solve the problems of interface/surface roughness, high defect density, large thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

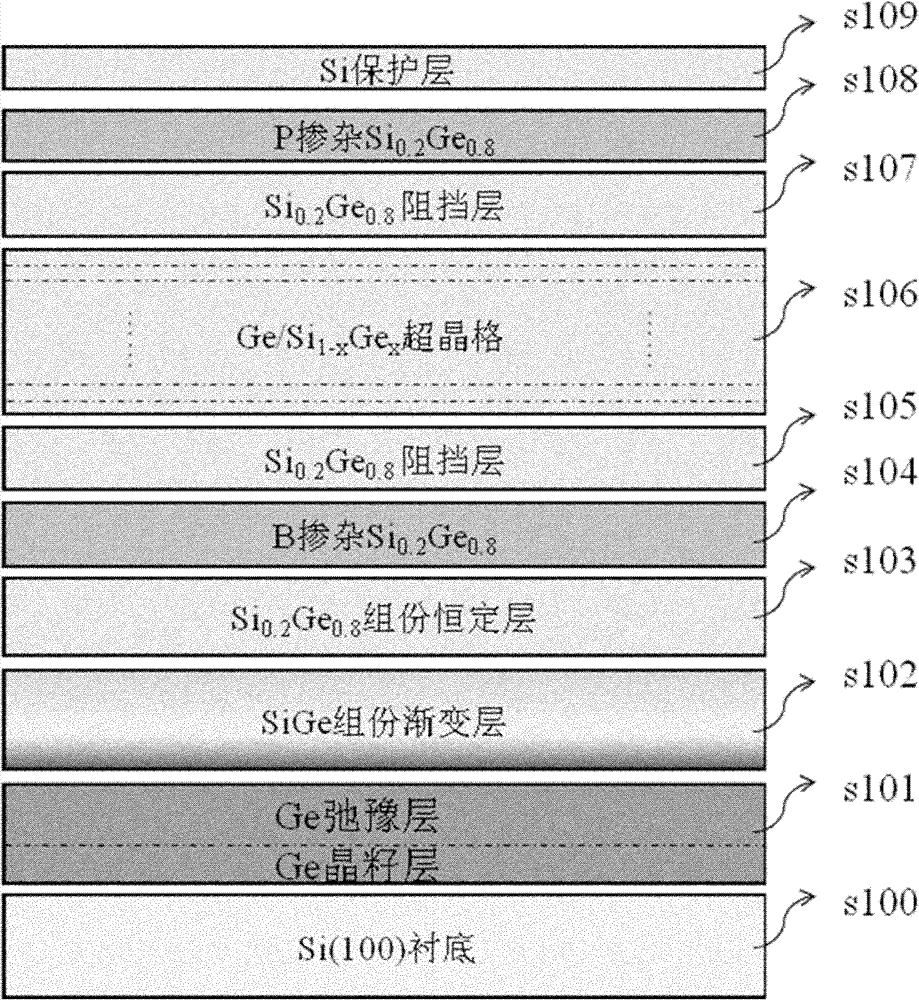

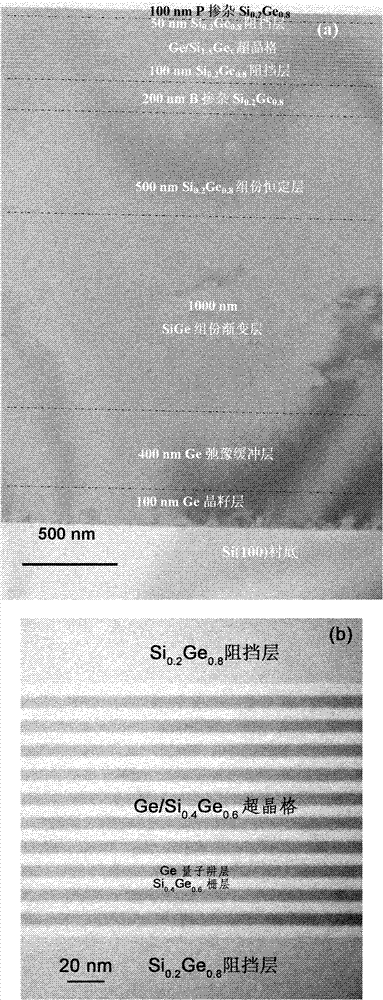

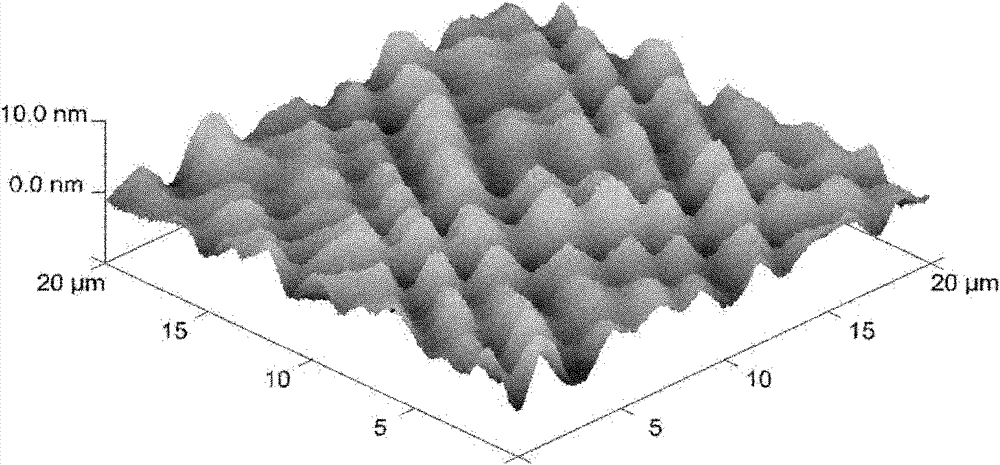

[0060] A high quality Ge / Si 1-x Ge x The preparation process of the superlattice structure is as follows: figure 1 As shown, the preparation of Ge / Si with 10 periods 0.4 Ge 0.6 superlattice, comprising the following steps:

[0061] In step s100, four 4-inch, 6-inch, 8-inch and 12-inch Si (100) wafers are respectively prepared as Si substrates.

[0062] Step s101, growth of Ge relaxation buffer layer: based on 4-inch, 6-inch, 8-inch and 12-inch Si substrates respectively, at 400 ° C with GeH 4 is the gas phase precursor, H 2 For carrier gas, 10% GeH 4 / H 2The gas flow rate is 150sccm, the growth chamber pressure is 100Torr, and a Ge seed layer with a thickness of 100nm is deposited respectively; keep the growth atmosphere unchanged, and then deposit a thickness of 400 nm on the four deposited Ge seed layers at 700°C. The Ge buffer layer of nm is annealed in situ (epitaxial growth chamber) at 850° C. for 10 minutes after completion, and the pressure of the growth chamber...

Embodiment 2

[0079] A 50-period Ge / Si 0.35 Ge 0.65 The preparation of superlattice structure comprises the following steps:

[0080] In step s100, a 4-inch Si wafer is prepared as a Si substrate.

[0081] Step s101, growth of the Ge relaxation buffer layer: on the basis of a 4-inch Si substrate, first at 400 ° C with GeH 4 is the gas phase precursor, H 2 For carrier gas, 10% GeH 4 / H 2 The gas flow rate is 150sccm, the growth chamber pressure is 100Torr, and a Ge seed layer with a thickness of 100nm is deposited respectively; keep the growth atmosphere unchanged, and then deposit Ge with a thickness of 400nm on the deposited Ge seed layer at 700°C. The buffer layer was annealed in situ (in the epitaxial growth chamber) at 850° C. for 10 minutes after completion, and the growth chamber pressure was kept at 100 Torr during annealing to obtain a fully strain-relaxed Ge relaxation buffer layer.

[0082] Step s102, the growth of the composition-graded SiGe buffer layer: on the basis of th...

Embodiment 3

[0097] A 100-period Ge / Si 0.3 Ge 0.7 The preparation of superlattice structure comprises the following steps:

[0098] In step s100, a 12-inch Si wafer is prepared as a Si substrate.

[0099] Step s101, growth of the Ge relaxation buffer layer: based on a 12-inch Si substrate, first at 400 ° C with GeH 4 is the gas phase precursor, H 2 For carrier gas, 10% GeH 4 / H 2 The gas flow rate is 150sccm, the growth chamber pressure is 100Torr, and a Ge seed layer with a thickness of 100nm is deposited respectively; keep the growth atmosphere unchanged, and then deposit Ge with a thickness of 400nm on the deposited Ge seed layer at 700°C. The buffer layer was annealed in situ (in the epitaxial growth chamber) at 850° C. for 10 minutes after completion, and the growth chamber pressure was kept at 100 Torr during annealing to obtain a fully strain-relaxed Ge relaxation buffer layer.

[0100] Step s102, the growth of the composition-graded SiGe buffer layer: on the basis of the rela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com