Method for separating and recovering lithium and cobalt from positive electrode material of lithium battery

A positive electrode material, separation and recovery technology, applied in the direction of battery recovery, recycling technology, waste collector recovery, etc., can solve the problems of low lithium recovery rate, high lithium content, high impurity content of cobalt products, etc., to achieve high economic benefits and social benefits, achieve recycling, and eliminate adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

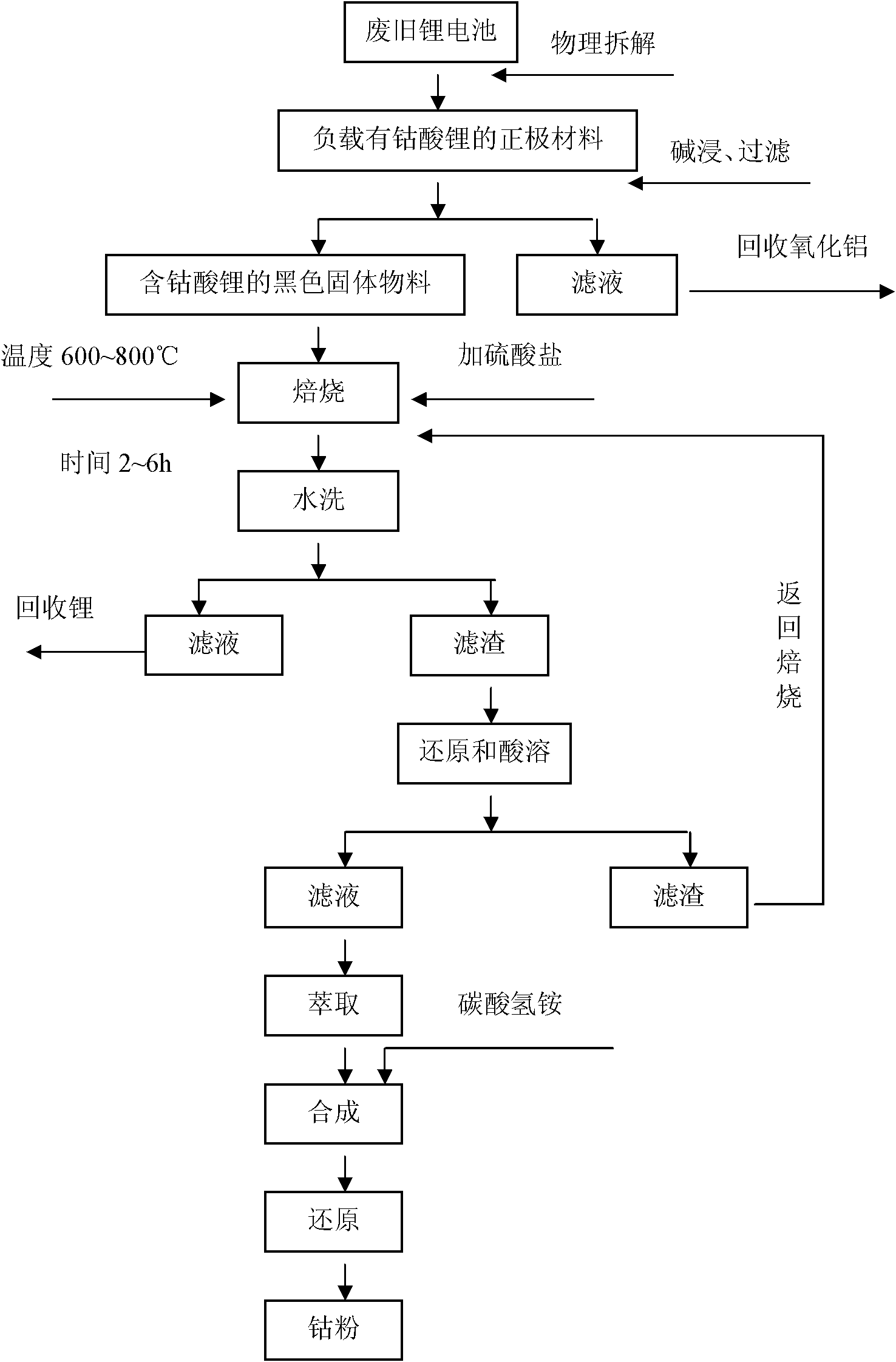

[0035] A method for separating and recovering lithium and cobalt from lithium battery cathode materials includes the following steps:

[0036] (1) Physical dismantling and alkaline leaching: Discharge the waste lithium battery and perform physical dismantling to obtain a positive electrode material loaded with lithium cobaltate on the aluminum foil; add the positive electrode material to the sodium hydroxide solution at a solid-liquid ratio of 1:3, Adjust the end-point pH to 13, and stir at 70°C for 0.5 hours, while stirring with alkaline immersion, and then filter to separate the aluminum foil to obtain a black solid material containing lithium cobaltate;

[0037] (2) Roasting and washing: Weigh 50g of black solid materials, add 50g of magnesium sulfate, mix, and roast at 800℃ for 2 hours to obtain 54.2g of roasting slag. Add pure water at a solid-liquid ratio of 1:3, and the temperature is 60℃. Stir for 2 hours and filter to obtain Li + Washing water with a concentration of 7.5g / ...

Embodiment 2

[0043] A method for separating and recovering lithium and cobalt from lithium battery cathode materials includes the following steps:

[0044] (1) Physical dismantling and alkaline leaching: Discharge the waste lithium battery and perform physical dismantling to obtain a positive electrode material loaded with lithium cobaltate on the aluminum foil; add sodium hydroxide solution to the positive electrode material at a solid-to-liquid ratio of 1:4, Adjust the end-point pH to 13, and stir at 80°C for 1 hour, while stirring with alkaline immersion, and then filter to separate the aluminum foil to obtain a black solid material containing lithium cobalt oxide;

[0045] (2) Roasting and washing: Weigh 50g of black solid material, add 50g of ammonium sulfate, mix, and roast at 700℃ for 3 hours to obtain 50.2g of roasted slag. Add tap water at a solid-liquid ratio of 1:3 and stir at 70℃. 1 hour, filter, get Li + Wash water with a concentration of 7.2g / L, and obtain 40.1g of filter residue,...

Embodiment 3

[0051] A method for separating and recovering lithium and cobalt from lithium battery cathode materials includes the following steps:

[0052] (1) Physical dismantling and alkaline leaching: Discharge the waste lithium battery and perform physical dismantling to obtain a positive electrode material loaded with lithium cobaltate on the aluminum foil; add the positive electrode material to the sodium hydroxide solution at a solid-to-liquid ratio of 1:5, Adjust the end point pH to 13, and stir at 60°C for 2 hours, while stirring with alkaline immersion, and then filter to separate the aluminum foil to obtain a black solid material containing lithium cobalt oxide;

[0053] (2) Roasting and washing: Weigh 50g of black solid material and add 40g of ammonium sulfate, mix, and roast at 600℃ for 6 hours to obtain 49.7g of roasted slag. Add pure water according to the solid-liquid ratio of 1:3 at a temperature of 75℃ Stir for 1 hour and filter to obtain Li + Wash water with a concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com