Method for preparing a mixture of lead carbonate and silver carbonate with waste residue gained from lithopone production

A technology of lead carbonate and silver carbonate, applied in the direction of lead carbonate, silver compounds, silver compounds, etc., can solve the problems of waste of resources, heavy metal pollution of the environment, no treatment and utilization methods, etc., and achieve low equipment investment costs, few by-products, Effects suitable for promotional applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

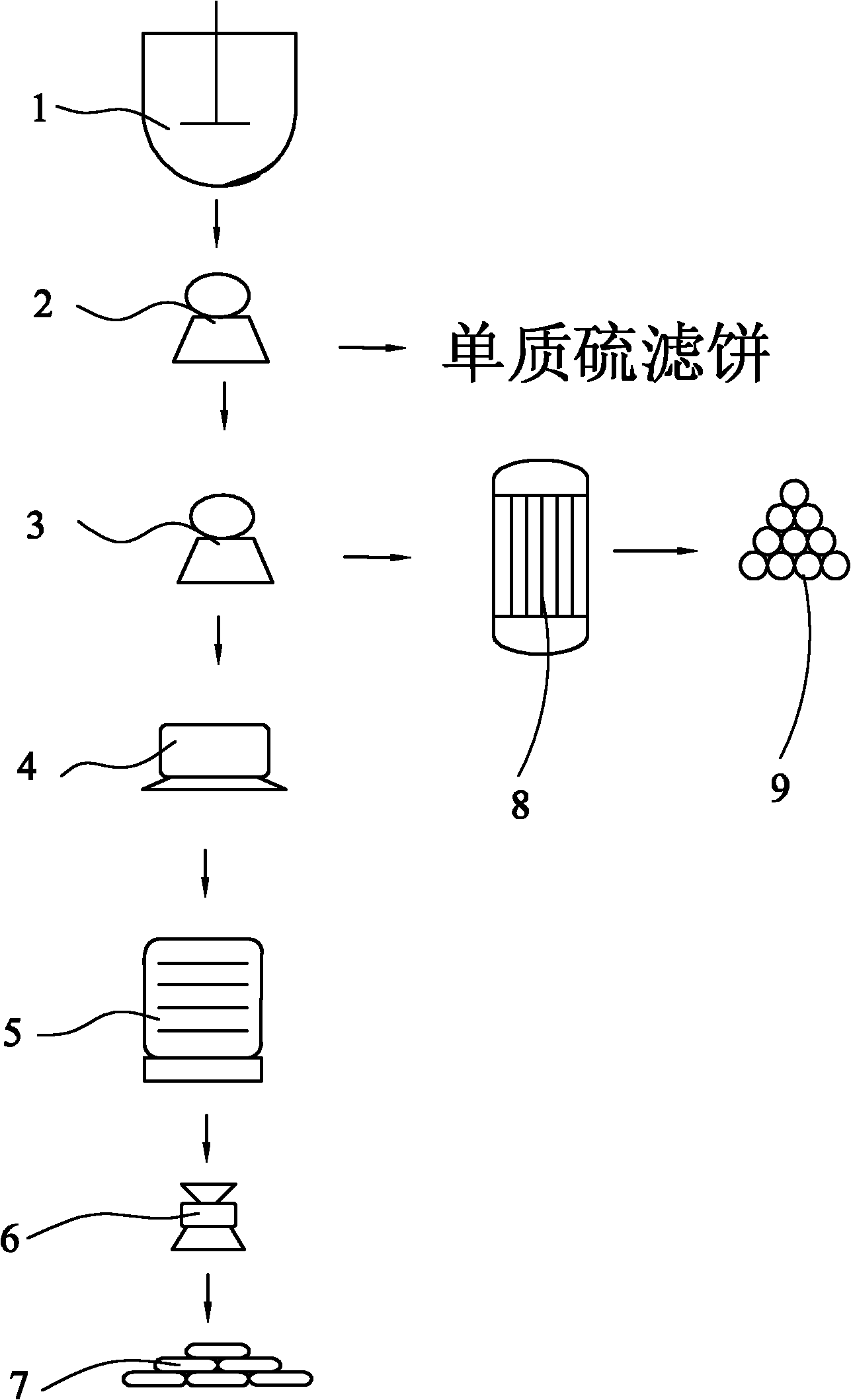

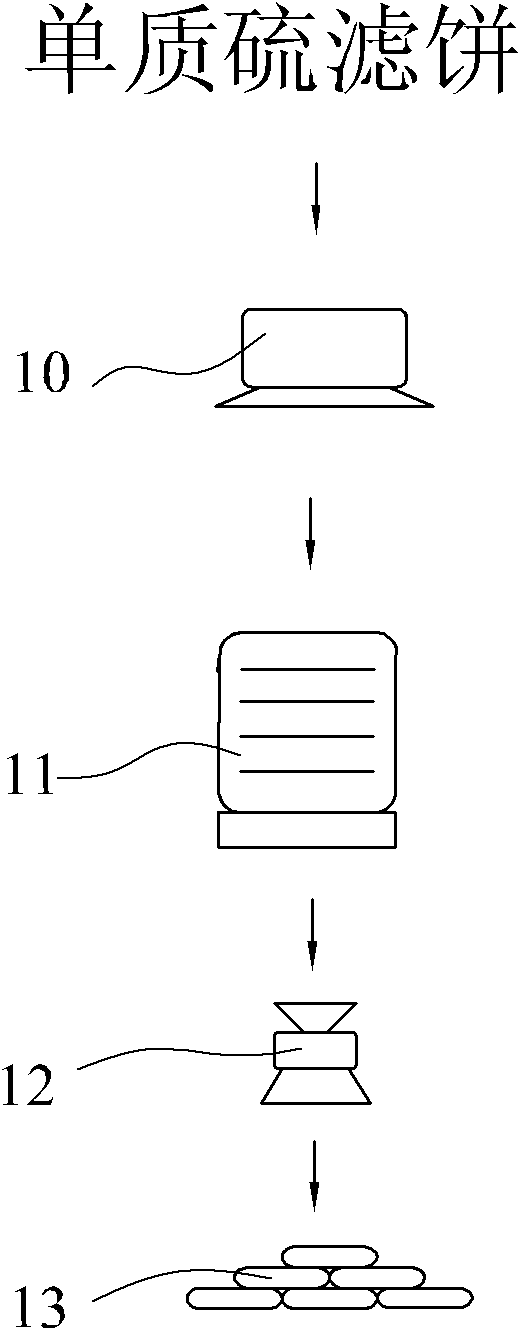

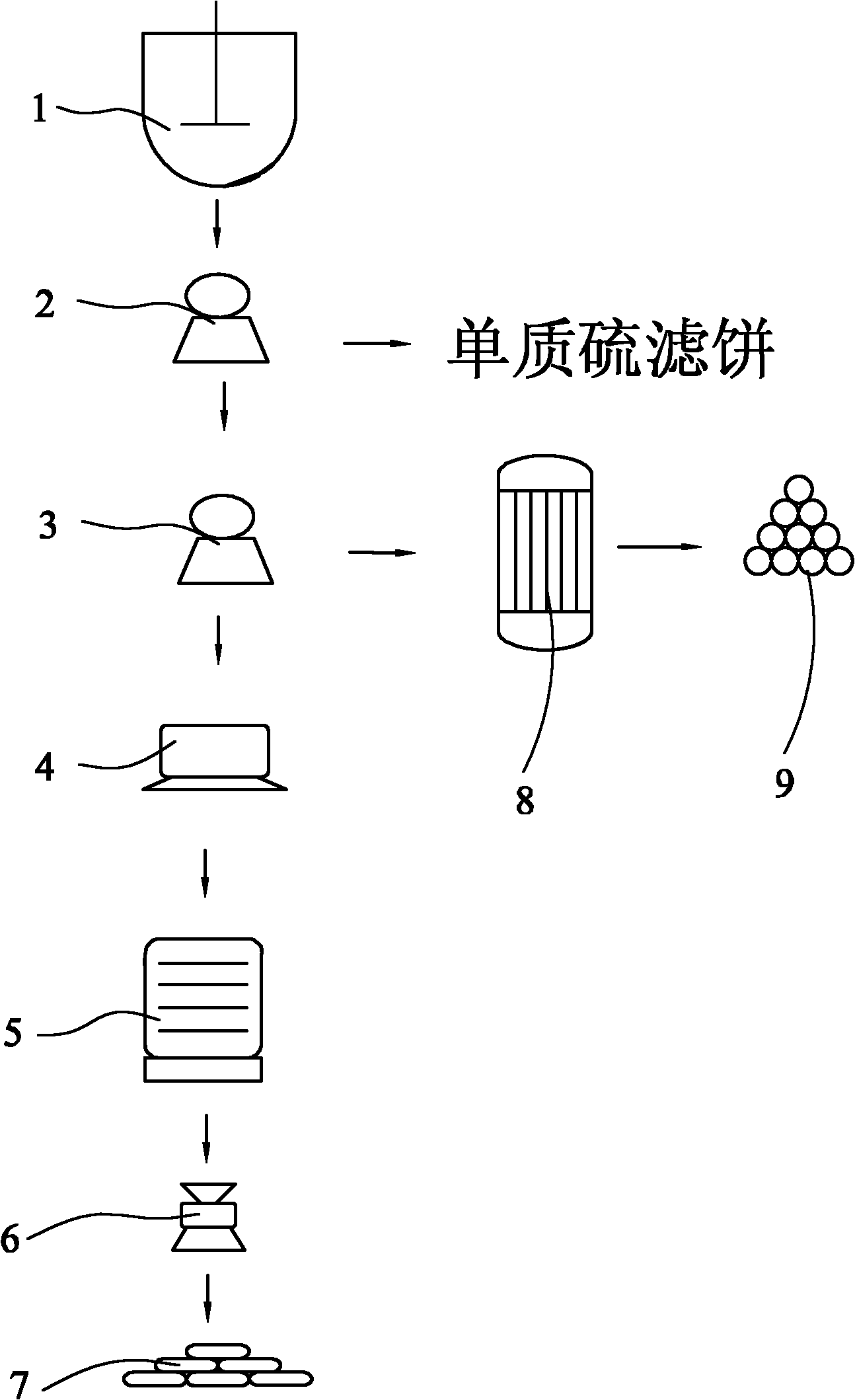

[0023] refer to figure 1 , a method for preparing lead carbonate and silver carbonate mixture with lithopone gained waste slag, comprising the following specific steps: weighing 500kg of lithopone gained waste slag, converting lead chloride content wherein to 173.15kg, and its molar content is : 529.51 moles; the silver chloride content is 17.5kg, and its molar content is: 121.95 moles, and it is ground into 80-120 mesh coarse powder, puts into corrosion-resistant reactor one (1) together with carbonic acid, makes corrosion-resistant reaction In the container, the ratio of the sum of the molar content of lead chloride and silver chloride to the molar content of carbonic acid is 1.12:1, and a chemical reaction occurs under gentle stirring to obtain lead carbonate, silver carbonate, sodium chloride and elemental A mixture of sulfur; the mixture containing lead carbonate, silver carbonate and elemental sulfur is roughly filtered through filter one (2) to obtain a clarified microe...

Embodiment 2

[0027] refer to figure 1 , a method for preparing lead carbonate and silver carbonate mixture with lithopone gained waste slag, comprising the following specific steps: weighing 500kg of lithopone gained waste slag, converting lead chloride content wherein to 173.15kg, and its molar content is : 529.51 moles; the silver chloride content is 17.5kg, and its molar content is: 121.95 moles, and it is ground into 80-120 mesh coarse powder, puts into corrosion-resistant reactor one (1) together with carbonic acid, makes corrosion-resistant reaction In the container, the ratio of the molar content of lead chloride and silver chloride to the molar content of carbonic acid is 1.12:1.2, and a chemical reaction occurs under gentle stirring to obtain lead carbonate, silver carbonate, sodium chloride and elemental A mixture of sulfur; the mixture containing lead carbonate, silver carbonate, sodium chloride and elemental sulfur is roughly filtered through filter one (2) to obtain a clarifie...

Embodiment 3

[0031] refer to figure 1, a method for preparing lead carbonate and silver carbonate mixture with lithopone gained waste slag, comprising the following specific steps: weighing 500kg of lithopone gained waste slag, converting lead chloride content wherein to 173.15kg, and its molar content is : 529.51 moles; the silver chloride content is 17.5kg, and its molar content is: 121.95 moles, and it is ground into 80-120 mesh coarse powder, puts into corrosion-resistant reactor one (1) together with carbonic acid, makes corrosion-resistant reaction In the container, the ratio of the sum of the molar content of lead chloride and silver chloride to the molar content of carbonic acid is 1.12:0.8, and a chemical reaction occurs under gentle stirring to obtain lead carbonate, silver carbonate, sodium chloride and elemental A mixture of sulfur; the mixture containing lead carbonate, silver carbonate, sodium chloride and elemental sulfur is roughly filtered through filter one (2) to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com