New method for preparing porous hydrogel by adopting low temperature photopolymerization

A low-temperature photopolymerization and hydrogel technology is applied in the field of photopolymerization to prepare porous hydrogel materials, and achieves the effect of reducing cost, low equipment requirements and small shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

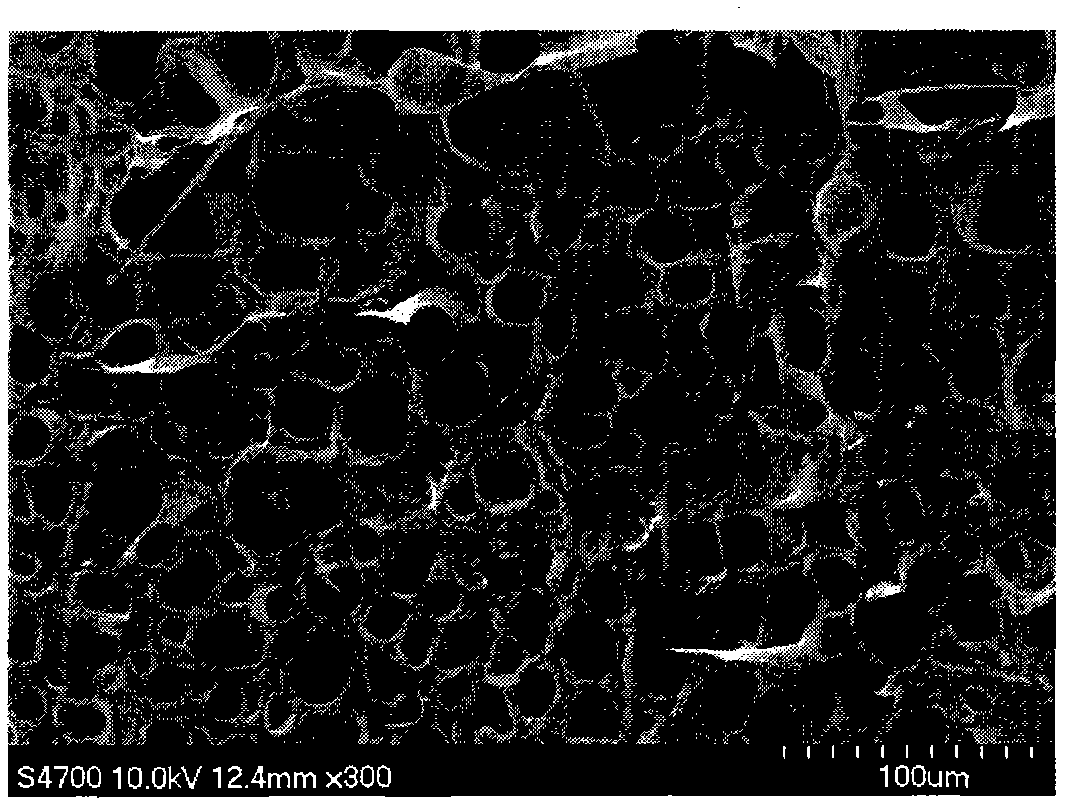

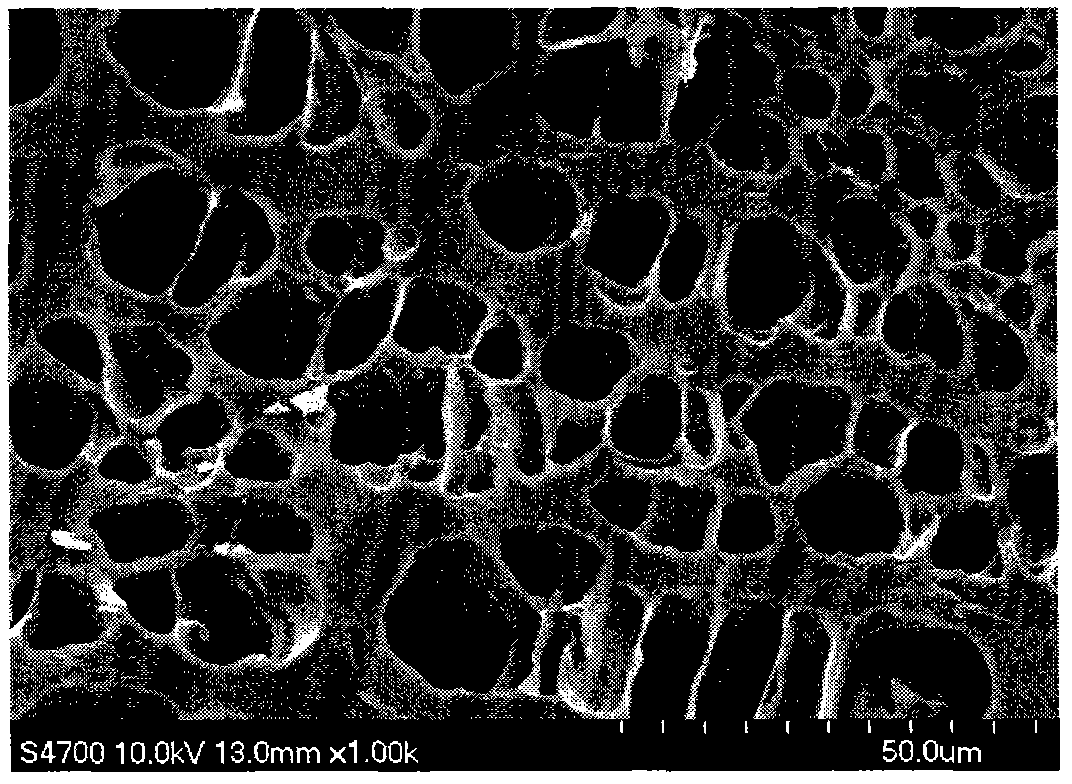

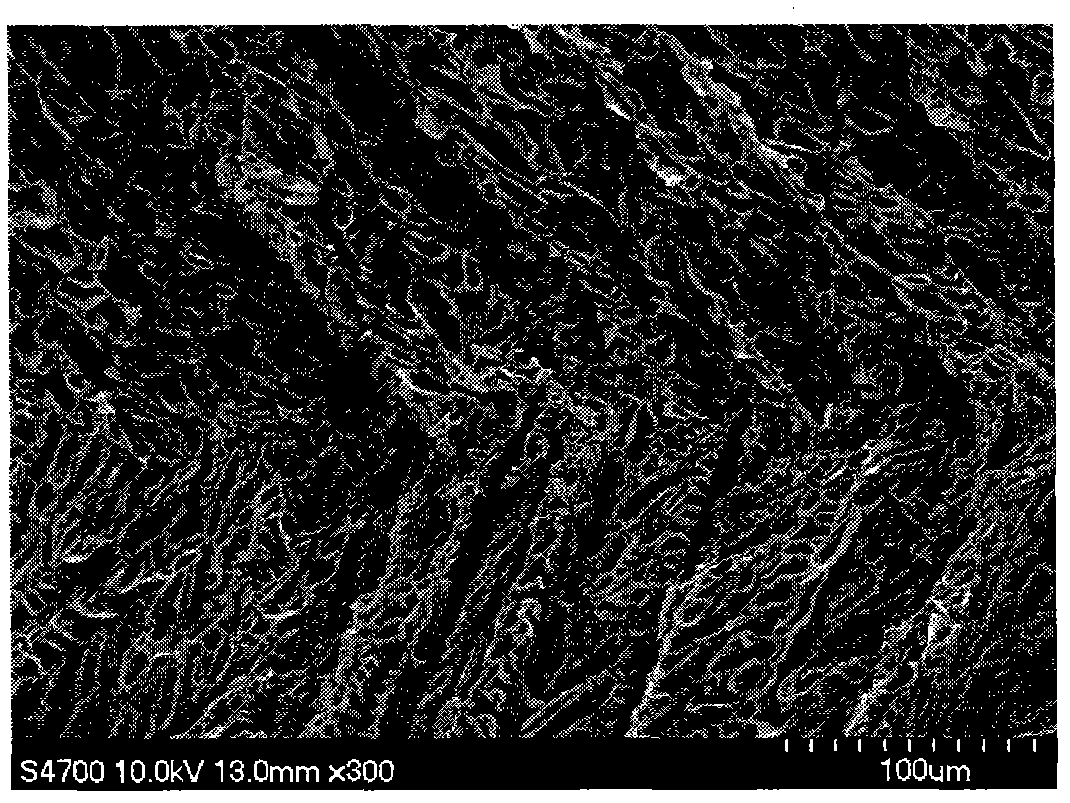

Image

Examples

Embodiment 1

[0014] (1) 2 (2-ethoxyethoxy) ethyl acrylate is the main resin, and the solvent is ethanol, accounting for 10% of the mass proportion of the acrylic resin, and then adding 0.1% of the photoinitiator of the mass proportion of the acrylic resin 1173.

[0015] (2) After mixing evenly, pour it into a light-transmitting airtight mold, put it into a low-temperature tank and irradiate it with a UV light source, and the temperature range is -40°C. Lighting time is 20 minutes. The illuminated polymer is taken out from the mold and put into a freeze dryer for freeze drying.

Embodiment 2

[0017] (1) 1.6-hexanediol diacrylate is the main resin, and the solvent is 1,6 dioxane, which accounts for 100% of the mass proportion of the acrylic resin, and then adds 0.5% of the photoinitiator TPO of the mass proportion of the acrylic resin .

[0018] (2) After mixing evenly, pour it into a light-transmitting airtight mold, put it into a low-temperature tank and irradiate it with a UV light source, and the temperature range is -20°C. Lighting time is 10 minutes. The illuminated polymer is taken out from the mold and put into a freeze dryer for freeze drying.

Embodiment 3

[0020] (1) Trimethylolpropane triacrylate is used as the main resin, and the solvent is ethyl acetate, accounting for 200% of the mass proportion of the acrylic resin, and then adding 2% of the photoinitiator 907 of the mass proportion of the acrylic resin.

[0021] (2) After mixing evenly, pour it into a light-transmitting airtight mold, put it into a low-temperature tank and irradiate it with a UV light source, and the temperature range is -5°C. Lighting time is 15 minutes. The illuminated polymer is taken out from the mold and put into a freeze dryer for freeze drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com