Method for preparing Ag-Pb-Sb-Te-Se thermoelectric material

An ag-pb-sb-te-se, thermoelectric material technology, which is applied in the fields of polycrystalline material growth, chemical instruments and methods, and ultra-high pressure application processes, etc. Special preparation process and other problems, to achieve the effect of suitable for large-scale industrial production, low thermal conductivity, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

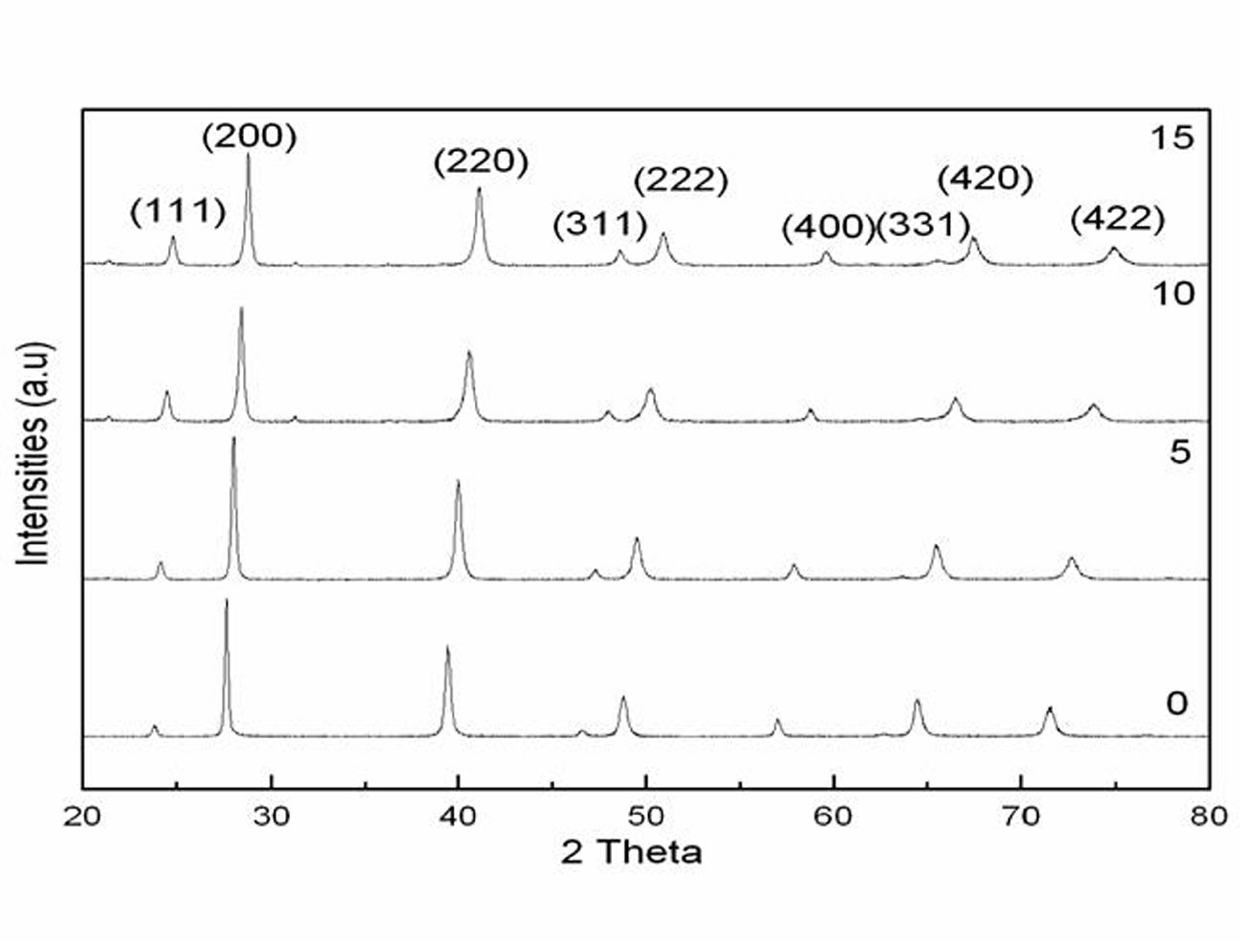

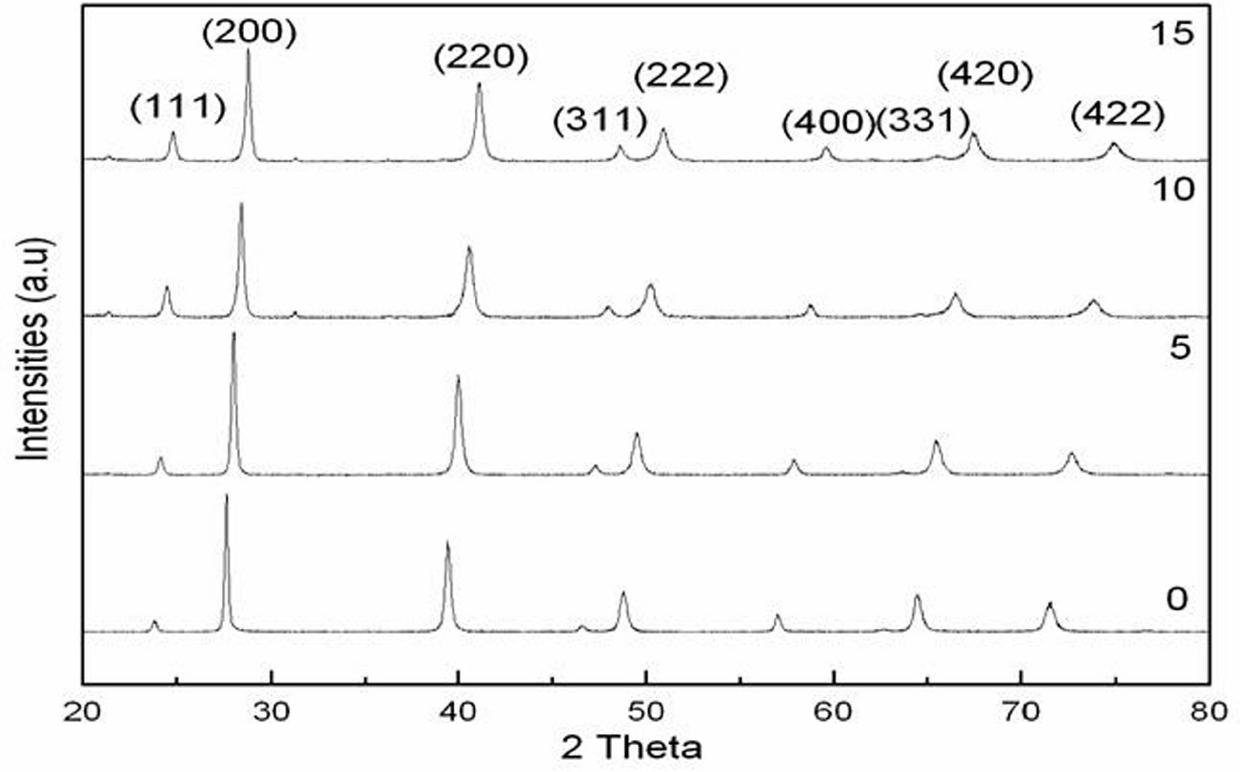

[0021] Preparation of Ag 0.8 Pb 18 SbT 20-x Se x For thermoelectric materials, the value of x is 0, that is, when x=0, the preparation of Ag 0.8 Pb 18 SbT 20 Thermoelectric materials, the steps are as follows:

[0022] The first step, material selection and ingredients: the raw materials are high-purity Ag powder (purity 99.9%), Pb powder (purity 99.9%), Sb powder (purity 99.999%) and Te powder (purity 99.999%); 0.8 Pb 18 SbT 20 Stoichiometric ratio Weigh the raw materials, and mix them in a vacuum glove box under the protection of argon for 1 hour, so that the raw materials are fully mixed and even;

[0023] The second step, sintering: put the above-mentioned homogeneously mixed raw materials into a steel mold, press them into discs with a hydraulic press, and put them into a six-sided high-temperature and high-pressure reaction chamber after assembly for high-temperature and high-pressure reaction. The synthesis pressure is set to 4 GPa, the temperature is 930°C, h...

Embodiment 2

[0027] When x=5, prepare Ag 0.8 Pb 18 SbT 15 Se 5 Thermoelectric materials, the steps are as follows:

[0028] The first step, material selection and ingredients: the raw materials are Ag powder with purity ≥99.9%, Pb powder with purity ≥99.9%, Sb powder with purity ≥99.999%, Te powder with purity ≥99.999% and Se powder with purity ≥99.95%; by Ag 0.8 Pb 18 SbT 15 Se 5 Stoichiometric ratio Weigh the raw materials, and mix them in a vacuum glove box under the protection of argon for 1 hour, so that the raw materials are fully mixed and even;

[0029] The second step, sintering: put the uniformly mixed raw materials into a steel mold, and use a hydraulic press to press them into discs. After assembly, put them into a six-sided high-temperature and high-pressure reaction chamber for high-temperature and high-pressure reaction. The preparation pressure is set to 4 GPa, the temperature is 960 ° C, heat preservation and pressure holding for 20 minutes;

[0030] The third ste...

Embodiment 3

[0033] When x=10, prepare Ag 0.8 Pb 18 SbT 10 Se 10 Thermoelectric materials, the steps are as follows:

[0034] The first step, material selection and ingredients: the raw materials are high-purity Ag powder (purity 99.9%), Pb powder (purity 99.9%), Sb powder (purity 99.999%), Te powder (purity 99.999%) and Se powder (99.95% pure); by Ag 0.8 Pb 18 SbT 10 Se10 Weigh the raw materials and mix them in a vacuum glove box under the protection of argon for 1 hour, so that the raw materials are fully mixed and even;

[0035] In the second step, put the uniformly mixed above-mentioned raw materials into a steel mold, and use a hydraulic press to press them into discs. After the assembly is completed, put them into a six-sided high-temperature and high-pressure reaction chamber for high-temperature and high-pressure reaction. The preparation pressure is set to 4 GPa, the temperature is 990°C, and the temperature is kept for 20 minutes;

[0036] The third step is to cut off the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com