Method for preparing estrogen substitution template molecular imprinting solid phase micro extraction head

A technology that replaces templates and molecular imprinting, applied in the field of analysis and detection, can solve the problems of leakage, difficult elution, affecting the measurement accuracy, etc., and achieve the effect of avoiding leakage interference, large adsorption capacity, and good identification performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

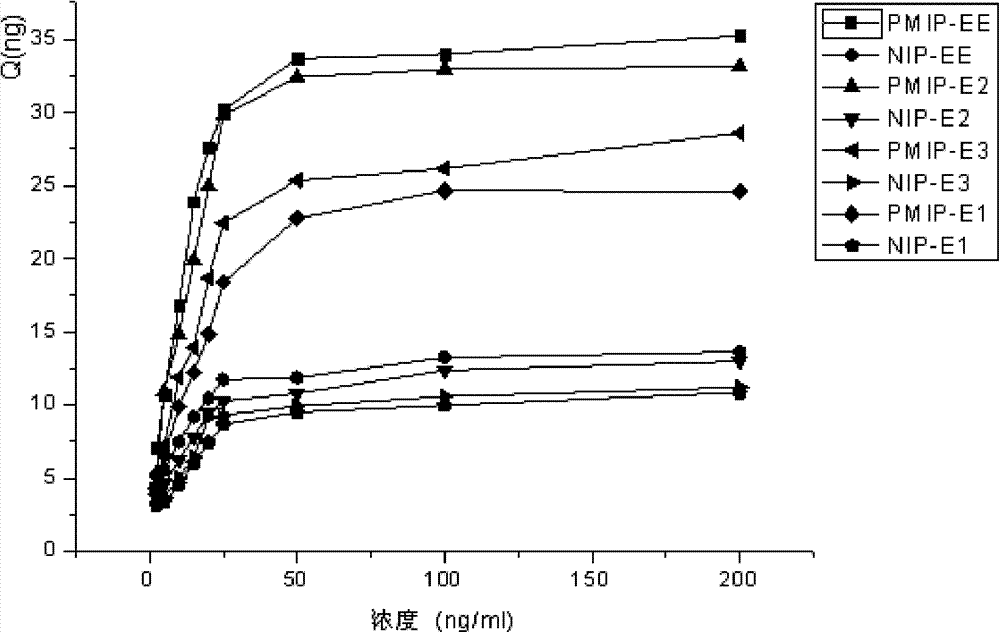

Embodiment 1

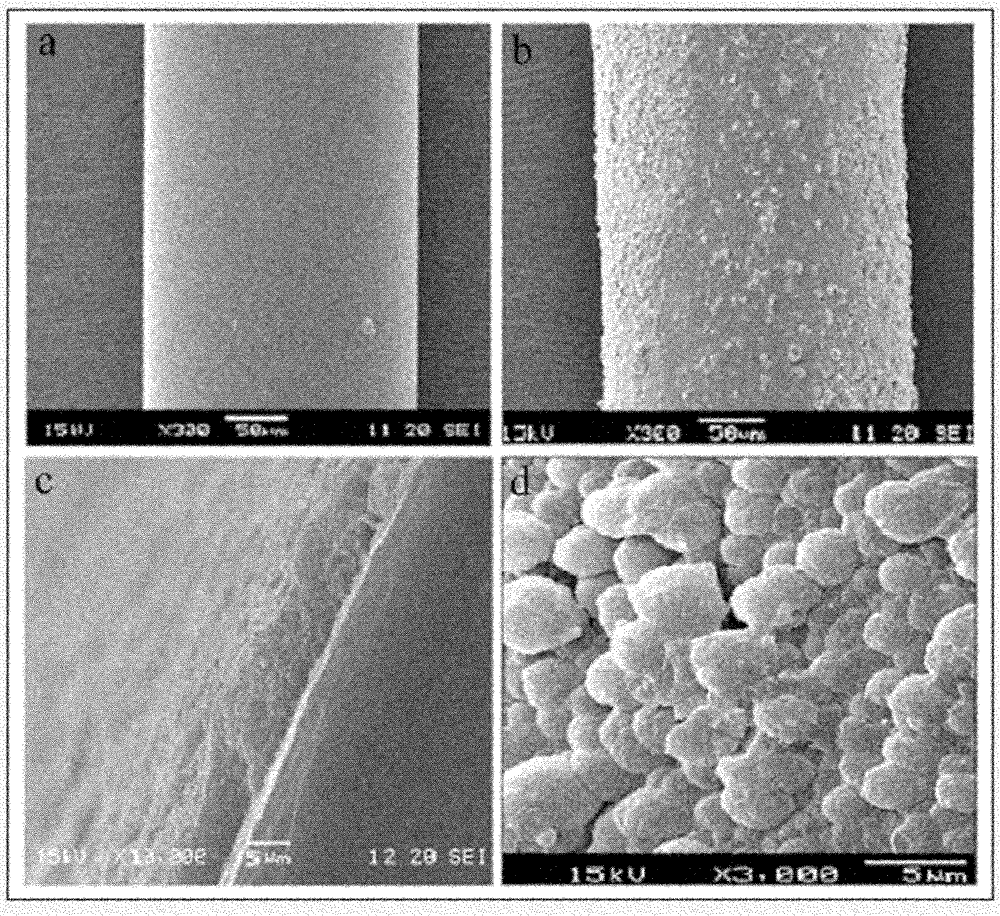

[0038] Quartz fiber (200 μm in diameter, 3 cm in length, Nanjing Feidis Fiber Mechatronic Engineering Manufacturing Center) was first soaked in acetone for 1 h to remove the protective layer, then soaked in 1 mol / L sodium hydroxide for 1 h, 0.1 mol / L hydrochloric acid Soak in water for 1 hour, wash with deionized water to remove residual acid on the surface until neutral, vacuum dry and activate at 70°C for 2 hours, and place it in γ-methacryloxypropyltrimethoxysilane with a concentration of 10% by mass after drying Silanize in acetone solution for 1.5 h, wash the remaining reaction solution on the surface with methanol, and blow dry with nitrogen gas for later use.

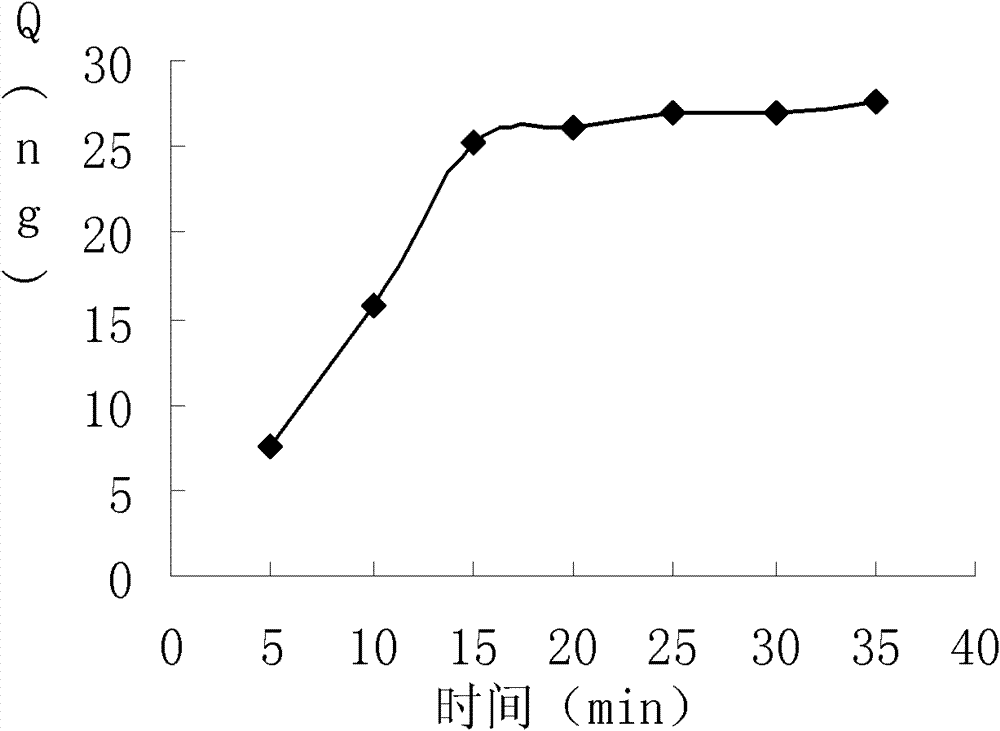

[0039] Mix 0.5mmol 17-ethylestradiol and 156mg trifluoromethacrylic acid in 40mL toluene, pre-polymerize for 6h, then add 119μL 4-vinylpyridine (the amount of trifluoromethacrylic acid and 4-vinylpyridine in moles ratio of 1:1), and pre-polymerize again after mixing for 6 hours, add 398.6 μL ethylene glycol dimet...

Embodiment 2

[0041] Quartz fibers (100 μm in diameter and 4 cm in length) were first soaked in acetone for 1 hour, then in 1 mol / L sodium hydroxide for 1 hour, in 0.1 mol / L hydrochloric acid for 1 hour, and washed with deionized water to remove residual acid on the surface. Activation by vacuum drying at 70°C for 2 hours, after drying, put it in 20% γ-methacryloxypropyltrimethoxysilane acetone solution for silanization for 2 hours, and wash the remaining reaction solution on the surface with methanol Afterwards, blow dry with nitrogen gas for later use.

[0042] Mix 0.5mmol 17-ethylestradiol and 156mg trifluoromethacrylic acid in 40mL methanol, prepolymerize for 6h, then add 119μL 4-vinylpyridine, mix well, prepolymerize again for 6h, add 398.6μL ethylene glycol Dimethacrylate and 30mg azobisisobutyronitrile (making the mol ratio of the replacement template molecule, functional monomer and crosslinking agent be 1:4:4, the molar weight of the initiator is 15% of the replacement template mol...

Embodiment 3

[0044] Quartz fibers (200 μm in diameter and 4 cm in length) were first soaked in acetone for 1 hour, then in 1 mol / L sodium hydroxide for 1 hour, in 0.1 mol / L hydrochloric acid for 1 hour, and washed with deionized water to remove residual acid on the surface. Reaction, vacuum drying and activation at 70°C for 2 hours, after drying, put it in a solution of γ-methacryloxypropyltrimethoxysilane acetone with a mass percent concentration of 30% for silanization for 1.5 hours, and wash the residual reaction on the surface with methanol After liquid, blow dry with nitrogen gas for later use.

[0045] Mix 0.5mmol 17-ethylestradiol and 312mg trifluoromethacrylic acid in 40mL toluene, pre-polymerize for 6h, then add 238μL 4-vinylpyridine, mix for another 6h, add 1.6mL ethylene glycol Dimethacrylate and 30mg azobisisobutyronitrile (the molar ratio of the substitute template molecule, functional monomer and crosslinking agent is 1:8:8, and the molar amount of the initiator is 15% of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com