Method for pretreating wastewater produced during producing metribuzin pesticide

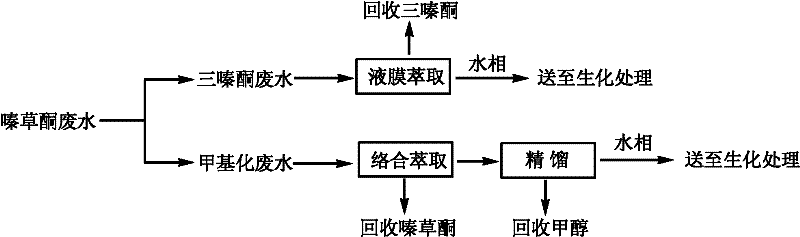

A technology for the production of wastewater and metrizone, which is applied in natural water treatment, multi-stage water/sewage treatment, extracted water/sewage treatment, etc., can solve the problems of lengthy treatment process, no literature reports, high energy consumption, etc., and achieve easy Biochemical, good industrialization promotion value, effect of solving wastewater treatment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

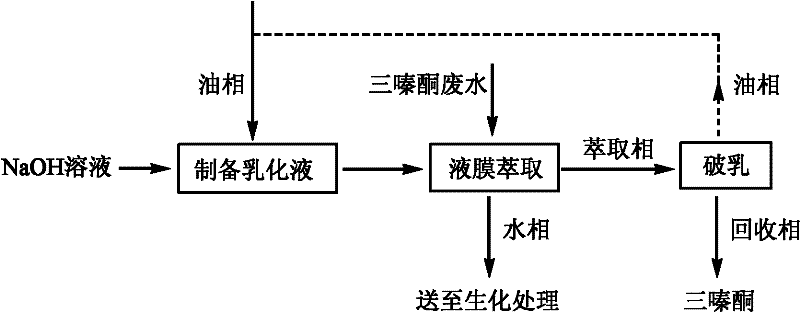

[0030] Embodiment 1: Liquid membrane separation technology reclaims triazone in triazone wastewater

[0031] Take 30L of surfactant L-113A, 60L of additive liquid paraffin and 910L of film solvent aviation kerosene to form an oil phase, put it into an emulsifier, turn on the emulsifier, add 500L of sodium hydroxide solution with a mass fraction of 15%, and shear at a high speed of 10 In minutes, a milky white water-in-oil emulsion is produced. Take 200L of the emulsion and disperse it in 3000L of triazone wastewater, control the rotation speed at 150 rpm, stir and extract for 15 minutes, let it stand for stratification, and after the lower water phase is clarified, the water phase enters the biochemical treatment device; the extraction phase 205L enters the electrostatic crusher After 60 minutes of demulsification in the emulsion machine, 130L of the oil phase was separated and reused for milk making; 75L of the water phase (recovery phase), which contained 12% triazone, could...

Embodiment 2

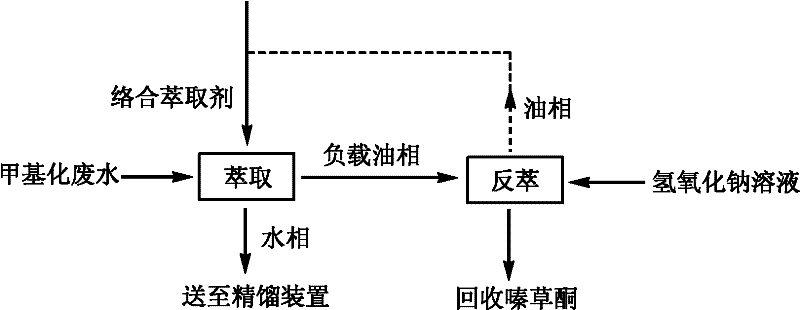

[0033] Example 2: Recycling of mecitrione in methylation wastewater by complex extraction technology

[0034] Take 30L of N23530L and 70L of aviation kerosene to make a complex extraction agent, take 20L and disperse it into 520L of mecitrione wastewater with pH = 3, control the rotation speed at 150rpm, stir and extract for 30min, let it stand for stratification, and separate the oil and water after the lower water phase is clarified. The phase and water phase enter the methanol recovery unit of the rectification tower to obtain 21L of the loaded oil phase, add 3L of 15% sodium hydroxide solution, extract for 30min, stand for stratification, separate the oil phase 19.5L, the water phase 4.5L, and the oil phase It is reused for the treatment of methylated wastewater, and the water phase is a solution containing 11.5% metrizone, which is recovered and used to prepare the wettable powder of metrizone.

[0035] After testing the treated wastewater, COD was 16200mg / L, and the COD ...

Embodiment 3

[0036] Embodiment 3: Rectification recovers the methanol in the methylation waste water

[0037] Add 520L of methylated waste water after complex extraction to 1.6kg of sodium hydroxide to fix the alkali, adjust the pH to 7-8, send it to the rectification tower, heat it to boiling, and reflux for 1h. Ratio 5, distilled 26L. After analysis, the distillate is methanol with a content of 95%, which can be reused in the synthesis section of the product, mecitrione, and the bottom liquid enters the biochemical treatment device.

[0038] It is detected that the COD of the treated wastewater is 120mg / L, and the COD removal rate is 68.4%, which is biodegradable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com