Treatment method of 2-chloro-5-chloromethylpyridine production wastewater

A technology of chloromethylpyridine and treatment method, which is applied in the field of treatment of 2-chloro-5-chloromethylpyridine production wastewater, can solve problems that have not been effectively solved, and achieve resource utilization, good industrialization promotion value, and significant Effects of Economic and Environmental Benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The waste water used in the embodiment is taken from the 2-chloro-5-chloromethylpyridine production waste water (cyclopentadiene route synthesis route) of a chemical enterprise in Gansu. The water quality is as follows in Table 1:

[0041] Table 1 Wastewater Composition

[0042] project color pH COD (mg / L) Cl- (mg / L) Ammonia nitrogen (mg / L) Total nitrogen (mg / L) Inorganic phosphorus (mg / L) other CCMP hydrolysis wastewater Red Brown 0.5 194432 99582 20317 22271 15363 H+: 3.2mol / L CCMP alkaline washing water brown 6-7 158720 24895 203 3421 156 Salt content: 5%

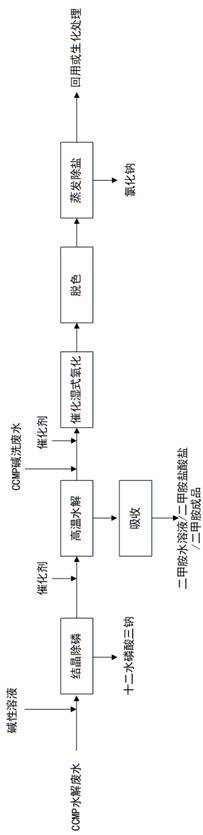

[0043] Such as figure 1 process shown.

[0044] The first step is to remove phosphorus by crystallization and recover trisodium phosphate. Take 20L of CCMP hydrolysis wastewater, add 4.5L of 32% sodium hydroxide, adjust the pH to alkaline, stir evenly, send it to a cooling crystallizer to cool down, crystallize at -5°C for 2h, take out the solid-liquid ...

Embodiment 2

[0052] The used waste water of embodiment 2 is identical with embodiment 1.

[0053] The first step is to remove phosphorus by crystallization and recover trisodium phosphate. Take 20L of CCMP hydrolysis wastewater, add 6.5L of sodium carbonate with a mass fraction of 20% and 2L of 32% sodium hydroxide, adjust the pH to alkaline, stir evenly, send it to a cooling crystallizer to cool down, and crystallize at 0°C for 3 hours , take out the solid-liquid separation, recover and obtain 3.1 kg of trisodium phosphate dodecahydrate, and the filtrate goes to the next step for processing.

[0054] The water quality of the filtrate was tested, and the COD was 78219mg / L, and the COD removal rate was 59.8%; the inorganic phosphorus content was 1020 mg / L, and the removal rate was 93.4%.

[0055] In the second step, high-temperature hydrolysis recovers dimethylamine. Take the filtrate after crystallization and phosphorus removal in the previous step, add 5.5L of sodium hydroxide solution ...

Embodiment 3

[0061] The waste water used in the embodiment is taken from the 2-chloro-5-chloromethylpyridine production waste water (cyclopentadiene route synthesis route) of a chemical enterprise in Shandong. The water quality is as follows in Table 2:

[0062] Table 2

[0063] project color pH COD (mg / L) Cl- (mg / L) Ammonia nitrogen (mg / L) Total nitrogen (mg / L) Inorganic phosphorus (mg / L) other CCMP hydrolysis wastewater Red Brown 0.5 305555 127638 44427 44530 32740 H+: 4.7mol / L CCMP alkaline washing water brown 6-7 93650 18357 283 327 230 Salt content: 3%

[0064] The first step is to remove phosphorus by crystallization and recover trisodium phosphate. Take 20L of CCMP hydrolysis wastewater, add 4.5L of sodium carbonate with a mass fraction of 20% and 4.5L of 32% sodium hydroxide, adjust the pH to alkaline, stir evenly, send it to a cooling crystallizer to cool down, and crystallize at 6°C After 1 hour, the solid-liquid separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com