Pervaporation alcohol permselective membrane and preparation method thereof

A technology of alcohol-preferential permeation membrane and pervaporation, which is applied in the field of pervaporation-preferential alcohol permeation membrane and its preparation, can solve the problems of inability to surpass silicon-containing materials, low flux of permeation membrane, poor mechanical properties, etc., and achieve film-forming properties High efficiency, convenient operation, stable structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

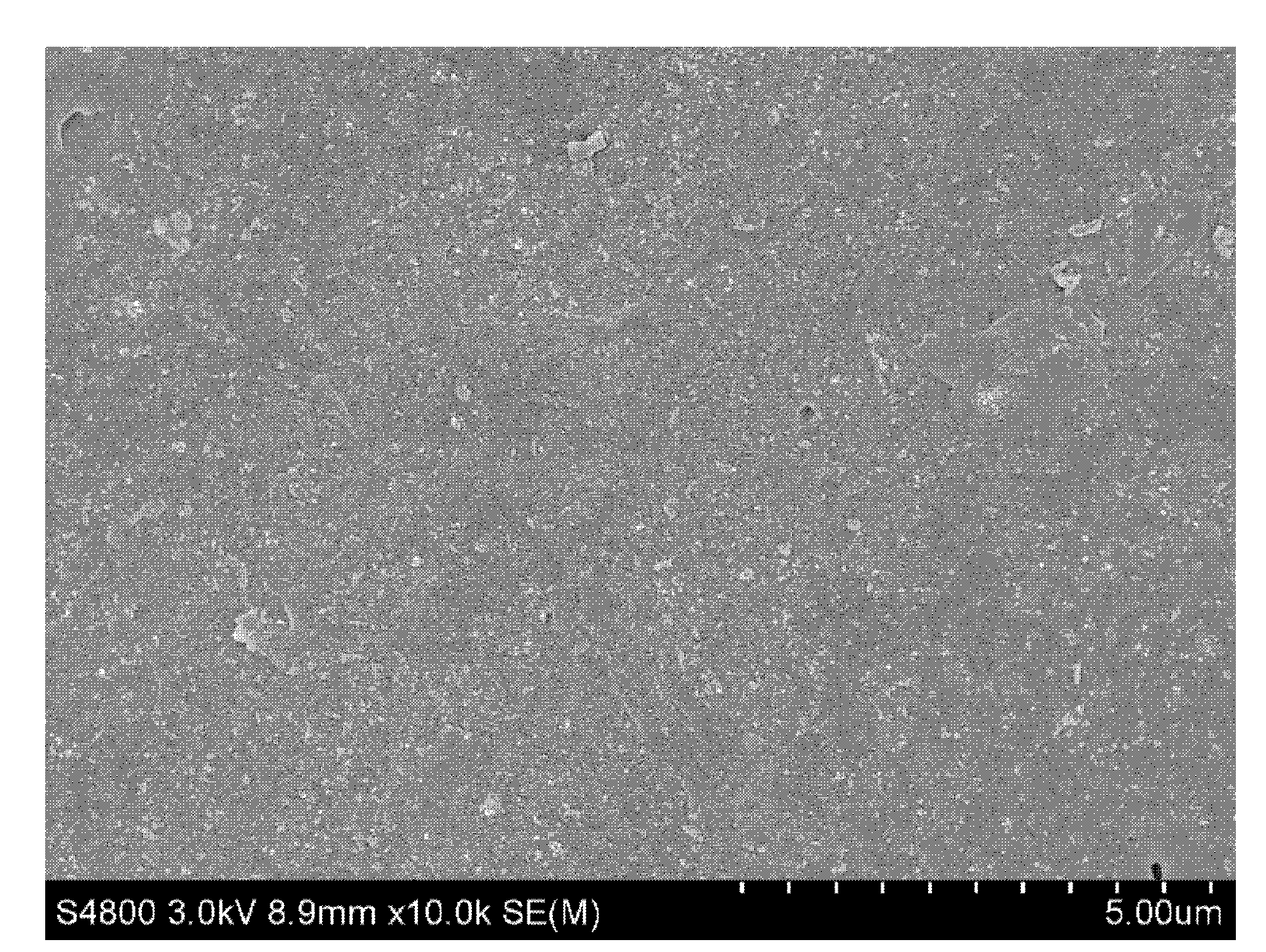

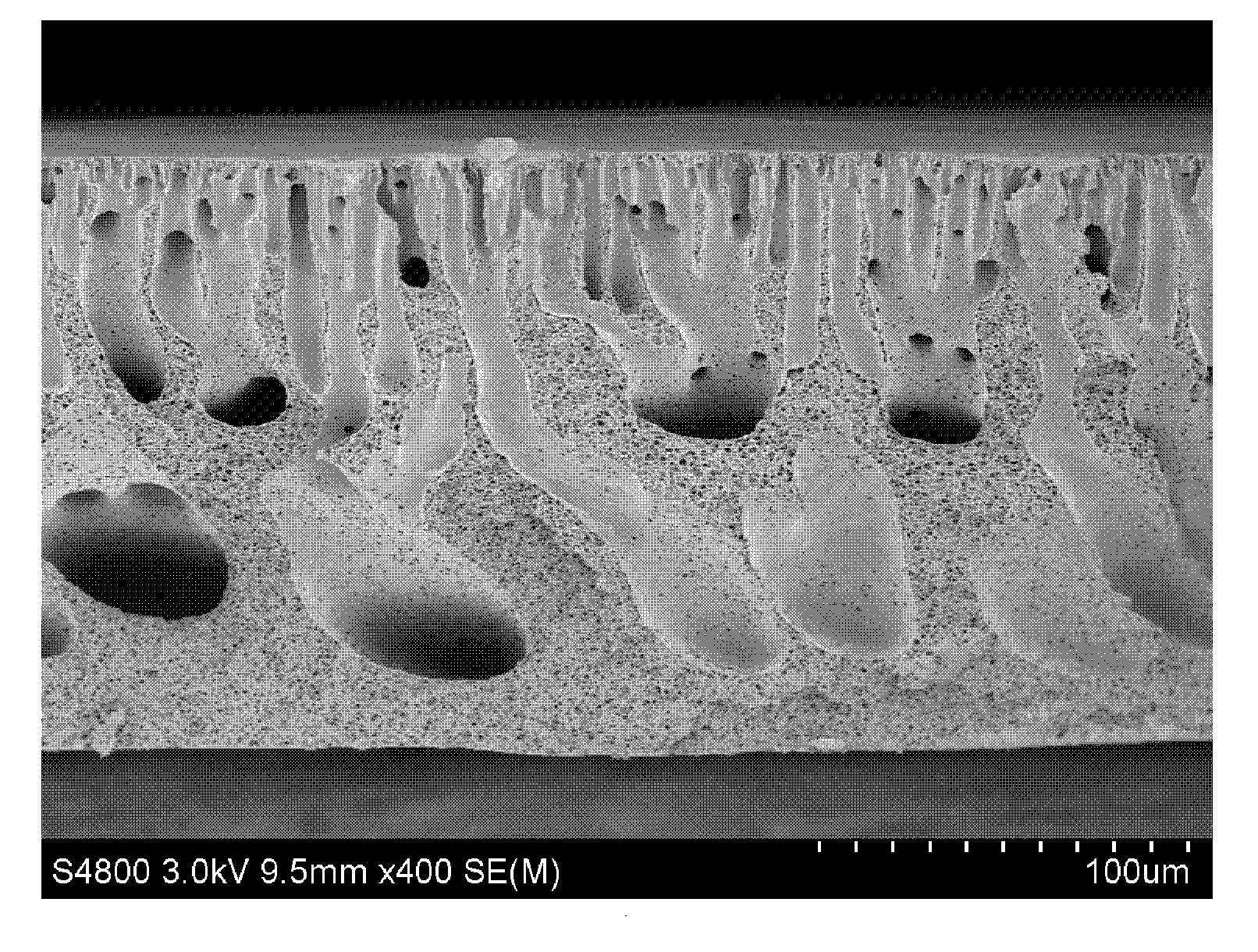

Image

Examples

Embodiment 1

[0030] 1) Equipped with casting solution:

[0031] Mix 10 parts of dried P(VDF-HFP) (Mw=150000, Mn=100000, PDI=1.83) with 2 parts of porogen PVP and 88 parts of solvent DMAc, stir and heat vigorously in an oil bath at 80°C for 24 hours , and then placed in an oven at 60°C for defoaming to form a film-making material. The film-making material is stored in an oven, that is, when the film is scraped, the temperature of the film-casting liquid is 60°C.

[0032] 2) Scratch film:

[0033] Take the casting solution out of the oven, scrape the film on a completely dry glass plate, set the scraper knife to 700 μm, and put it into water at 25°C immediately. Replace the gel bath at intervals of 2 to 3 hours until the phase inversion process is complete, then take out the membrane and dry it in an oven.

[0034] The P(VDF-HFP) asymmetric pervaporation preferential alcohol permeation membrane obtained above is applied to the separation of ethanol water system, ethanol is preferentially ...

Embodiment 2

[0036] 1) Equipped with casting solution:

[0037] Mix 20 parts of dried P(VDF-HFP) (Mw=180,000, Mn=120,000, PDI=1.74) with 5 parts of porogen LiCl and 75 parts of solvent ACT, and heat vigorously in a 40°C oil bath for 48 hours , and then placed in an oven at 40°C for defoaming to form a film-making material. The film-making material is stored in an oven, that is, when the film is scraped, the temperature of the film-casting solution is 40°C.

[0038] 2) Scratch film:

[0039] Take the above casting solution out of the oven, scrape the film on a completely dry glass plate, set the scraper knife to 1000 μm, place it in the air for 20s, and then put it into a 25wt% methanol / 75wt% water mixed gel bath at 40°C middle. Replace the gel bath at intervals of 2 to 3 hours until the phase inversion process is complete, then take out the membrane and dry it in an oven.

[0040] The P(VDF-HFP) asymmetric pervaporation preferential alcohol permeation membrane obtained above is applied...

Embodiment 3

[0043] 1) Equipped with film-making materials:

[0044] Mix evenly 25 parts of dried P(VDF-HFP) (Mw=350000, Mn=150000, PDI=1.91) with 6.5 parts of porogen LiCl and 68.5 parts of solvent DMAc, and heat vigorously in an oil bath at 100°C for 12 hours , and then placed in an oven at 25°C for defoaming to form a film-making material. The film-making material is stored in an oven, that is, when the film is scraped, the temperature of the film-casting solution is 25°C.

[0045] 2), scraping film:

[0046] Take the above casting solution out of the oven, scrape the film on a completely dry glass plate, set the scraper knife to 500 μm, place it in the air for 15 seconds, and then put it into an ethanol gel bath at 4°C. Replace the gel bath at intervals of 2 to 3 hours until the phase inversion process is complete, then take out the membrane and dry it in an oven.

[0047] The P(VDF-HFP) asymmetric pervaporation preferential alcohol permeation membrane obtained above is applied to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com