Method for preparing Fe2O3/Ti-mesoporous composite material (MCM)-41

A technology of MCM-41 and ti-mcm-41, which is applied in the field of preparation of Fe2O3/Ti-MCM-41 mesoporous composite materials, can solve the problems of adsorption and selective catalysis, low utilization rate of sunlight, and inability to use Sunlight and other problems, to achieve the effect of improving photocatalytic reaction efficiency, high BET surface area and pore volume, and uniform pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

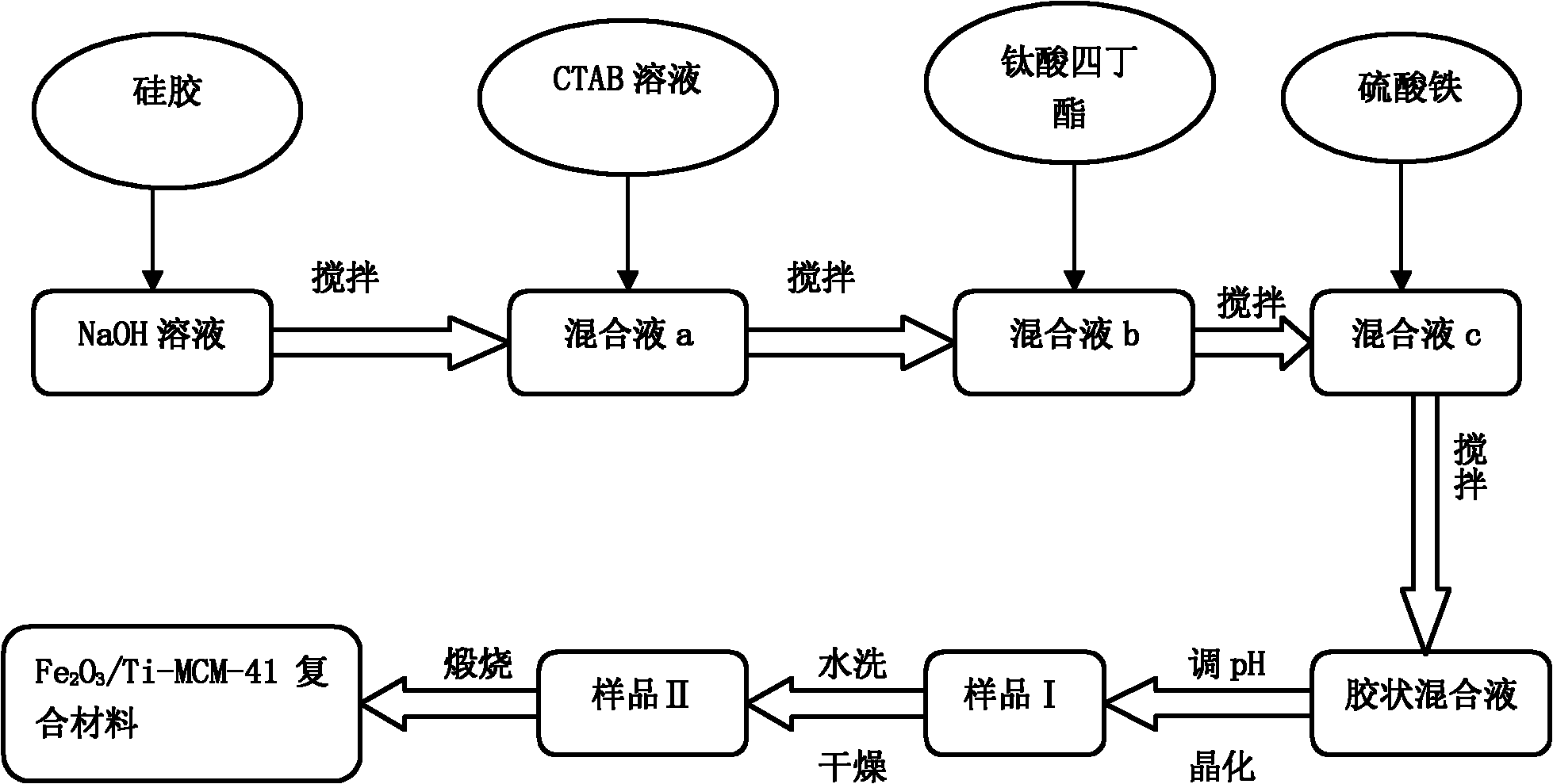

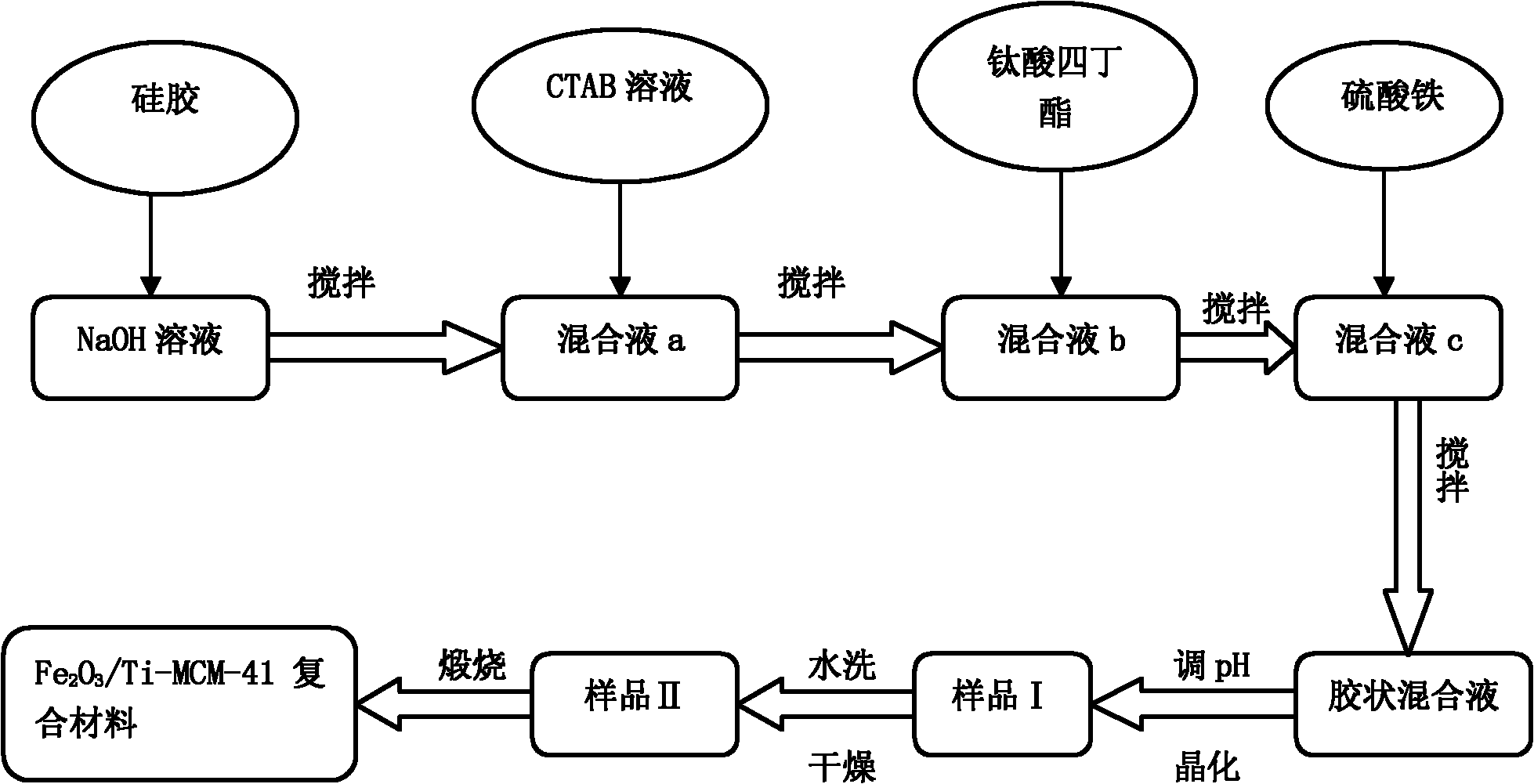

[0023] 1. Weigh 5g of 100-mesh silica gel and add it to 90ml of 1.5mol / l sodium hydroxide solution, and stir vigorously at a constant speed for 30min;

[0024] 2. Measure 60ml of CTAB solution with a mass fraction of 10% and add it to the mixed solution prepared in step a, and stir vigorously at a constant speed for 30 minutes;

[0025] 3. Measure 0.5ml of tetrabutyl titanate and add it to the mixture prepared in step b, and stir vigorously at a constant speed for 1 hour;

[0026] 4. Weigh 12g of ferric sulfate and add it to the mixed solution prepared in step c, and stir vigorously at a constant speed for 2 hours;

[0027] 5. Adjust the pH of the sample to 11.5 with 2mol / l HCl, and crystallize at 100°C for 48 hours;

[0028] 6. Wash the sample until neutral, and dry it in a blast drying oven at 100°C for 12 hours;

[0029] 7. Finally, put the dried sample into a muffle furnace and bake it at 300°C for 6 hours to obtain the Fe 2 o 3 / Ti-MCM-41 mesoporous composite.

Embodiment 2

[0031] 1. Weigh 8g of 100-mesh silica gel and add it to 90ml of 1.5mol / l sodium hydroxide solution, and stir vigorously at a constant speed for 35min;

[0032] 2. Measure 60ml of CTAB solution with a mass fraction of 10% and add it to the mixture prepared in step a, and stir vigorously at a constant speed for 35 minutes;

[0033] 3. Take 0.6ml of tetrabutyl titanate and add it to the mixture prepared in step b, and stir vigorously at a constant speed for 1 hour;

[0034] 4. Weigh 15g of ferric sulfate and add it to the mixed solution prepared in step c, and stir vigorously at a constant speed for 2h;

[0035] 5. Adjust the pH of the sample to 11.5 with 2mol / l HCl, and crystallize at 100°C for 45 hours;

[0036] 6. Wash the sample with water until neutral, and dry it in a blast drying oven at 100°C for 10 hours;

[0037] 7. Finally, put the dried sample into a muffle furnace and bake it at 300°C for 6 hours to obtain the Fe 2 o 3 / Ti-MCM-41 mesoporous composite.

Embodiment 3

[0039] 1. Weigh 5g of 200-mesh silica gel and add it to 90ml of 1.5mol / l sodium hydroxide solution, and stir vigorously at a constant speed for 35min;

[0040] 2. Measure 60ml of CTAB solution with a mass fraction of 10% and add it to the mixture prepared in step a, and stir vigorously at a constant speed for 35 minutes;

[0041] 3. Measure 0.8ml of tetrabutyl titanate and add it to the mixture prepared in step b, and stir vigorously at a constant speed for 2 hours;

[0042] 4. Weigh 12g of ferric sulfate and add it to the mixed solution prepared in step c, and stir vigorously at a constant speed for 3h;

[0043] 5. Adjust the pH of the sample to 11.5 with 2mol / l HCl, and crystallize at 100°C for 48 hours;

[0044] 6. Wash the sample until neutral, and dry it in a blast drying oven at 100°C for 12 hours;

[0045] 7. Finally, put the dried sample into a muffle furnace and bake it at 300°C for 6 hours to obtain the Fe 2 o 3 / Ti-MCM-41 mesoporous composite.

[0046] The mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com