Modified alkali lignin cement grinding aid and preparation method thereof

A technology of cement grinding aid and alkali lignin, applied in the field of cement grinding aid, can solve problems such as poor grinding aid enhancement ability, and achieve the effects of improved strength, simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 200 grams of alkaline pulping straw pulp black liquor acid analysis alkali lignin (weight percentage, solid content: 95%) and mix it with 400 grams of water, add sodium hydroxide to adjust the pH to 10.5, then heat to 60°C and stir to dissolve fully , adding 10 g of diethylene glycol monobutyl ether, and performing an activation reaction at 70° C. for 1.5 hours to obtain a reaction solution. Dissolve 10 grams of ammonium persulfate in 60 grams of water, slowly add it dropwise to the reaction solution at 60° C. within 30 minutes, and then carry out oxidation reaction at 80° C. for 2 hours. Then 20 g of glycerol was added and reacted at 85° C. for 1 hour. Cool to room temperature after the reaction to obtain a modified alkali lignin cement grinding aid liquid product.

Embodiment 2

[0033] Take 200 grams of alkali lignin alkaline pulping straw pulp black liquor acid analysis alkali lignin (weight percentage, solid content: 95%), mix it with 433 grams of water, add sodium hydroxide to adjust the pH to 10, and then heat to 70 ° C Stir to dissolve fully, add 15 g of n-octanol, and perform an activation reaction at 80° C. for 1 hour to obtain a reaction solution. Dissolve 30 grams of 50% hydrogen peroxide in 120 grams of water, slowly add it dropwise to the reaction solution at 70°C within 45 minutes, and then carry out oxidation reaction at 70°C for 3 hours. Then add 30 g of diethylene glycol, and react at 70° C. for 2 hours. Cool to room temperature after the reaction to obtain a modified alkali lignin cement grinding aid liquid product.

Embodiment 3

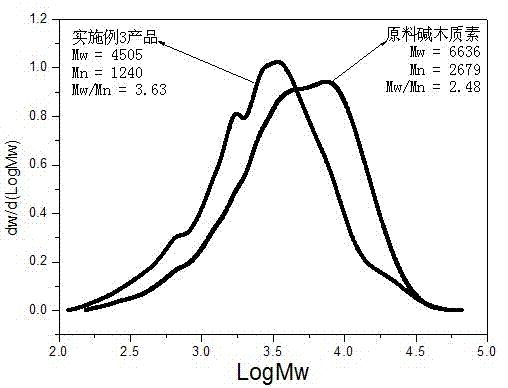

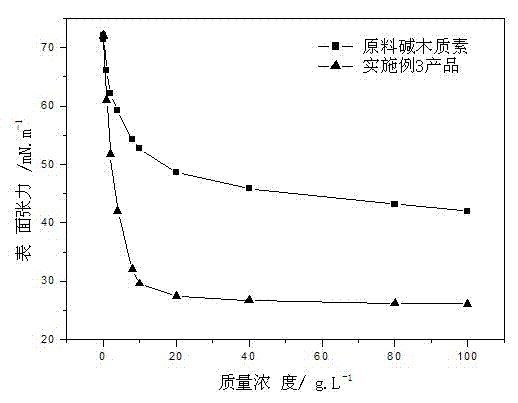

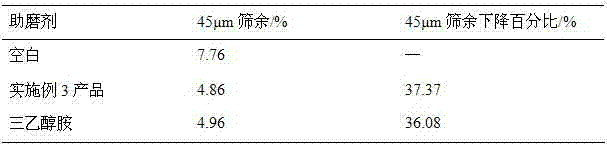

[0035]Take 200 grams of alkali lignin alkaline pulping straw pulp black liquor acid analysis alkali lignin (weight percentage, solid content: 95%), mix it with 560 grams of water, add sodium hydroxide to adjust the pH to 11, and then heat to 80 °C Stir to dissolve fully, add 20 g of n-decyl alcohol, and carry out activation reaction at 90° C. for 1.5 hours to obtain a reaction solution. Dissolve 20 grams of sodium perborate in 80 grams of water, slowly add it dropwise to the reaction solution at 80° C. within 60 minutes, and then carry out oxidation reaction at 90° C. for 4 hours. Then add 30 g of sodium gluconate and 10 g of dipropylene glycol mixture, and react at 90° C. for 1.5 hours. Cool to room temperature after the reaction to obtain a modified alkali lignin cement grinding aid liquid product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com