Conductive polymethyl methacrylate composite material and preparation method of the conductive polymethyl methacrylate composite material

A technology of polymethyl methacrylate and composite materials, which is applied to conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of lack of polar groups on the surface of carbon nanotubes, easy agglomeration and winding of carbon nanotubes, and weak affinity. and other problems, to achieve the effect of good conductivity, good durability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] At room temperature, weigh 2.5 g of carbon nanotubes and 2.5 g of aniline in a three-necked flask, mechanically stir for 15 minutes, and sonicate for 10 minutes, then add 0.1 g of hexadecane. Another 0.1 g of sodium cetyl sulfate was added into a beaker filled with 45 g of distilled water, and mechanically stirred for 15 minutes. Next, the solution in the beaker was poured into the above three-neck flask, mechanically stirred for 15 minutes, and ultrasonically homogenized for 10 minutes. Add 6.25g ammonium persulfate / 10g aqueous solution dropwise to initiate the polymerization reaction of aniline, and stop the reaction after 4 hours to obtain a dark green solution; centrifuge, wash with ethanol and water three times respectively, and obtain a modified carbon nanotube conductive powder. Next, 0.1 g of the conductive powder was dissolved in 5 g of methyl methacrylate and 10 g of N,N-dimethylformamide, and 0.3 g of hexadecane was added, and stirred and ultrasonicated for 1...

Embodiment 2

[0043] The same reaction steps as in Example 1, the mass ratio of modified carbon nanotube powder to methyl methacrylate is 10:100.

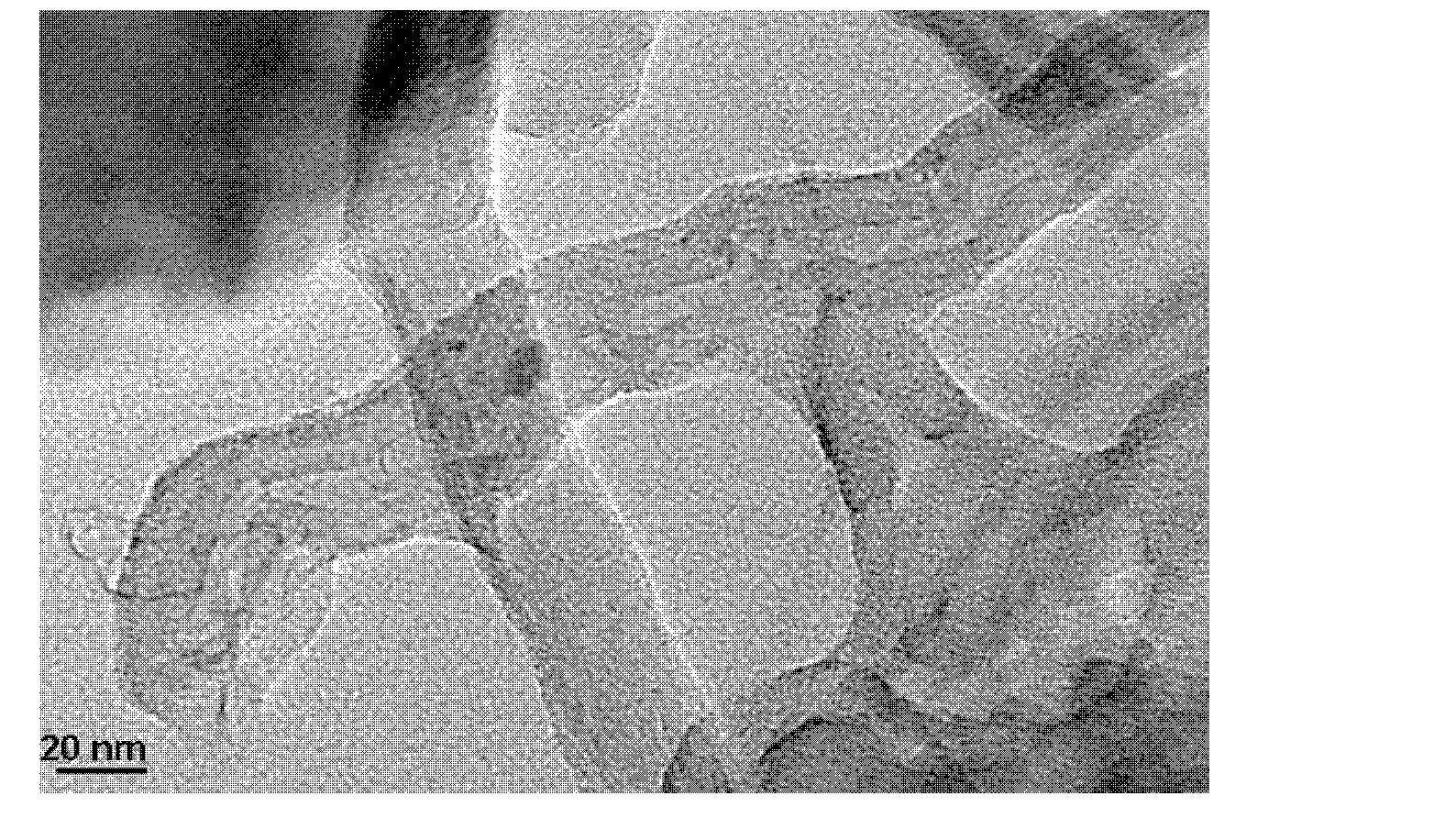

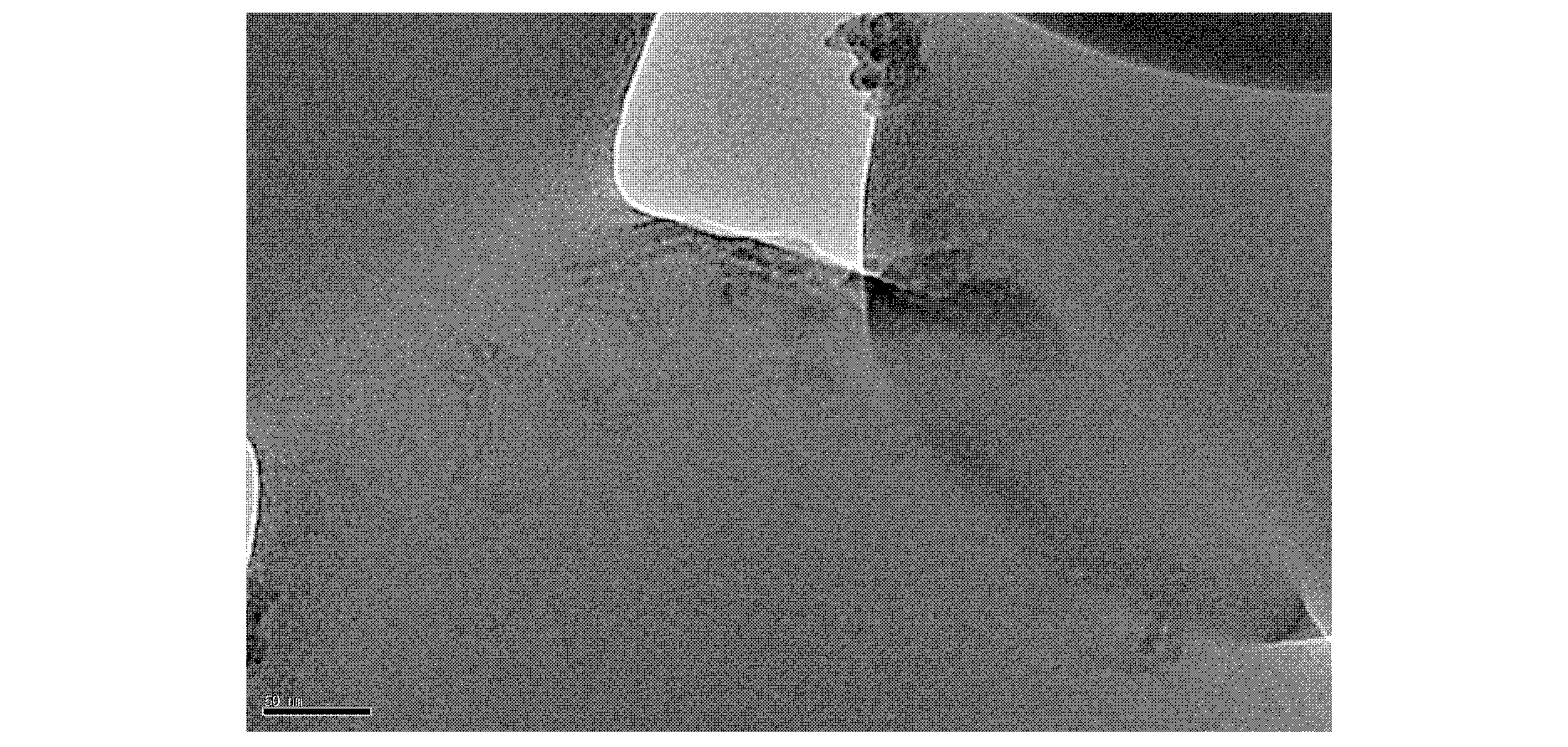

[0044] Depend on image 3 The TEM electron micrograph shows that the modified carbon nanotubes are well dispersed in polymethyl methacrylate and cross each other to form a network structure; and no carbon nanotubes are found in the place where polymethyl methacrylate does not exist , indicating that the modified carbon nanotubes have good compatibility with polymethyl methacrylate.

[0045] Using a four-probe resistivity tester, the conductivity of the composite material was measured to be 6.96×10 -3 S / cm.

Embodiment 3

[0047] The same reaction steps as in Example 1, the mass ratio of modified carbon nanotube powder to methyl methacrylate is 14:100.

[0048] The modified carbon nanotubes are well dispersed in polymethyl methacrylate and cross each other to form a network structure.

[0049] Using a four-probe resistivity tester, the electrical conductivity of the composite material was measured to be 4.202 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com