Preparation method of surface modified nano particles and application of product thereof

A technology of surface modification of nanometer and nanoparticle, applied in dyeing polymer organic compound treatment, fibrous filler, coating and other directions, can solve the problems of poor controllability of polymer chain segments, and achieve uniform chain length distribution and good dispersion. The effect of maintaining high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

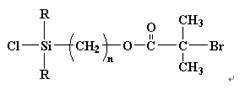

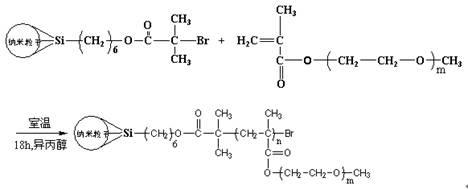

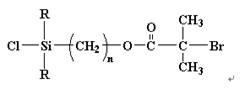

[0037] The first step is to anchor the ATRP surface initiator: add 20 grams of silica with a particle size of 50±5 nanometers to a mixed solvent containing 200ml toluene / 20ml isopropanol. In the mixed solvent, toluene and isopropanol The volume ratio is generally not more than 20:1. Stir at room temperature, add 5g of 2-bromoisobutyryl and 1.4g of triethylamine. Stir slowly at room temperature for 18 hours, filter off the solvent, wash the filter cake repeatedly with isopropanol, and dry the filter cake in a vacuum drying oven at room temperature to constant weight. Using X-ray photoelectron surface energy spectroscopy analysis, the surface of the nanoparticles has an absorption peak of bromine at 73 eV, indicating that the ATRP surface initiator has been grafted on the surface of silica.

[0038] The second step of graft polymerization: Disperse 10g of silica with ATRP surface initiator on the surface in 200ml of isopropanol, bubbling with nitrogen for 30min, adding 23mg of copp...

Embodiment 2

[0040] In the first step, 50 grams of magnesium difluoride with a particle size of 100±5 nanometers was added to a mixed solvent of 400ml toluene / 20ml isopropanol, stirred at room temperature, and 12.5g of silicodecane trichloride was added. 2-bromoisobutyryl and 4.5 g triethylamine. Stir slowly at room temperature for 18 hours, filter off the solvent, wash the filter cake repeatedly with isopropanol, and dry the filter cake in a vacuum drying oven at room temperature to constant weight. Using X-ray photoelectron surface energy spectroscopy analysis, the surface of the nanoparticles has an absorption peak of bromine at 73 eV, indicating that the ATRP surface initiator has been grafted on the surface of magnesium difluoride.

[0041] In the second step, 20g of silica with ATRP surface initiator on the surface was dispersed in 200ml of isopropanol, and nitrogen gas was introduced for 30 minutes, 46mg of copper monobromide, 100mg of pentamethyldiethylenetriamine (PMDETA) and 10g Ox...

Embodiment 3

[0043] The first step is to add 20 grams of titanium dioxide with a particle size of 25±5 nanometers to a mixed solvent of 200ml toluene / 10ml isopropanol, stir at room temperature, and add 5.5g of 2-bromosilyl trichloride Isobutyryl and 1.54g triethylamine. Stir slowly at room temperature for 18 hours, filter off the solvent, wash the filter cake repeatedly with isopropanol, and dry the filter cake in a vacuum drying oven at room temperature to constant weight. Using X-ray photoelectron surface energy spectroscopy analysis, the surface of the nanoparticles has an absorption peak of bromine at 73 eV, indicating that the ATRP surface initiator has been grafted on the surface of titanium dioxide.

[0044] In the second step, 10g of titanium dioxide with ATRP surface initiator on the surface was dispersed in 200ml of isopropanol, and nitrogen was blown for 30 minutes, and 23mg of copper monobromide, 50mg of bipyridine (bpy) and 1.2g of oxygen-free methacrylic acid were added. Hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com