Preparation method of low-temperature stable poly-alpha olefin oil product resistance reducer suspension system

A technology of low temperature stability and drag reducing agent, applied in the field of preparation of drag reducing agent suspension system, can solve the problems of increasing injection difficulty and production cost, obvious layering phenomenon, short storage time, etc., and achieves low cost, simple process and stable The effect of storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

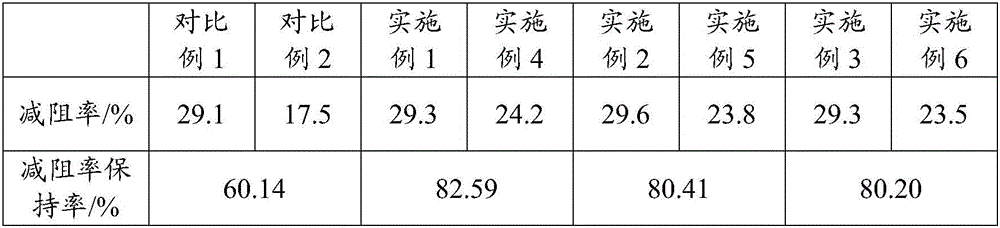

Examples

Embodiment 1

[0044] Add 100g of deionized water, 3000g of ethanol, 3000g of ethylene glycol, and 300g of n-heptane with a resistivity of 18MΩ·cm into a closed container, and stir and mix evenly at 180rad / min. Under heating at 45°C, add 30g of dodecyl 2-acrylate, 30g of hexadecyl methacrylate, 35g of benzenesulfonyl hydrazide, 35g of acetylhydrazide and 4g of zinc citrate, and stir evenly. Add 65g of emulsified silicone oil and 70g of polyoxyethylene polyoxypropanolamine ether, stir evenly at 60rad / min to form a dispersion, and cool to room temperature for use. Polyα-olefins with a molecular weight of 5 million to 8 million are treated in an oven at 90°C for 24 hours, quickly transferred to liquid nitrogen, taken out after 10 minutes, pulverized with a ball mill, passed through a 80-mesh sieve, and 2200g of the undersieve is quickly added to 600g The calcined clay and 100g of aluminum oxide were stirred by a paddle stirring device at 60 rad / min. Add it into the dispersion liquid at -30°C, ...

Embodiment 2

[0046]Add 120g of deionized water with a resistivity of 6.7MΩ·cm, 4000g of ethanol, 4000g of ethylene glycol, and 300g of n-heptane into a closed container, and stir and mix evenly at 240rad / min. Under heating conditions at 55°C, add 27g of dodecyl 2-acrylate, 27g of hexadecyl methacrylate, 27g of perfluoroalkyl ethyl acrylate, 50g of magnesium dodecyl sulfate, 50g of acetaldehyde n-propyl Thiol acetal, 2.5g gelatin and 2.5g sodium alginate, stir well. Add 75g of emulsified silicone oil and 85g of polyoxypropylene glyceryl ether, stir evenly at 60rad / min to form a dispersion, and cool to room temperature for later use. Polyα-olefins with a molecular weight of 5 million to 8 million are treated in an oven at 90°C for 36 hours, quickly transferred to liquid nitrogen, taken out after 20 minutes, pulverized with a ball mill, passed through a 60-mesh sieve, and 2600g of the undersieve is taken and quickly added to 300g Aluminum oxide, 300g calcium stearate, and 100g magnesium stea...

Embodiment 3

[0048] Add 110g of deionized water with a resistivity of 13.2MΩ·cm, 3500g of ethanol, 3500g of ethylene glycol, and 300g of n-heptane into a closed container, and stir at 180rad / min to mix evenly. Under the condition of heating at 50°C, 76g of polylaurate methacrylate, 45g of benzenesulfonyl hydrazide, 45g of ethanedithiol and 4.5g of sodium alginate were added and stirred evenly. Add 75g of polyoxyethylene polyoxypropanolamine ether and 80g of polydimethylsiloxane, and stir at 60rad / min to form a dispersion liquid, which is cooled to room temperature for use. Polyα-olefins with a molecular weight of 5 million to 8 million are treated in an oven at 90°C for 30 hours, quickly transferred to liquid nitrogen, taken out after 20 minutes, crushed with a ball mill, passed through a 60-mesh sieve, and 2400g of the undersieve is taken and quickly added to 100g Al2O3 and 700g talc are stirred at 90rad / min by a paddle stirring device. Add it to the dispersion at -25°C, then add 6g n-oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com