Preparation method of tin carbon composite material for negative electrode of lithium ion batteries

A technology of lithium-ion batteries and composite materials, which is applied in the field of preparation of tin-carbon composite materials for lithium-ion battery negative electrodes, can solve the problems of increasing the first irreversible capacity and sacrificing the overall specific capacity, so as to reduce irreversible capacity, improve charge and discharge efficiency, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

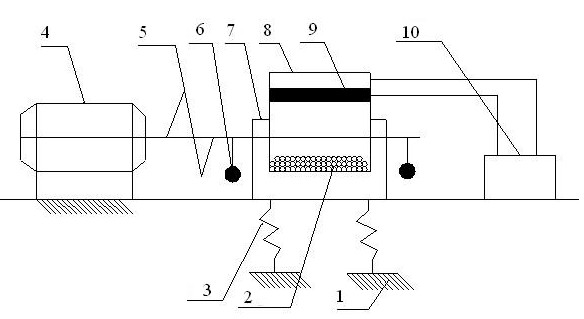

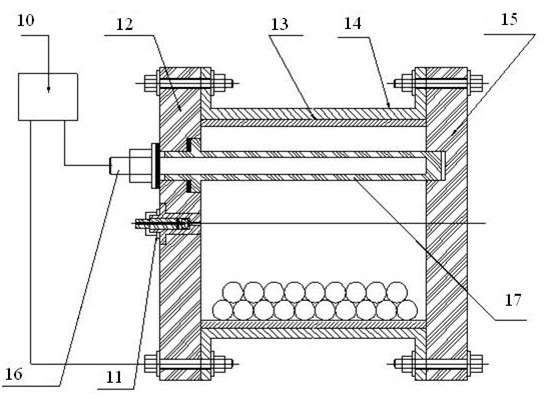

Method used

Image

Examples

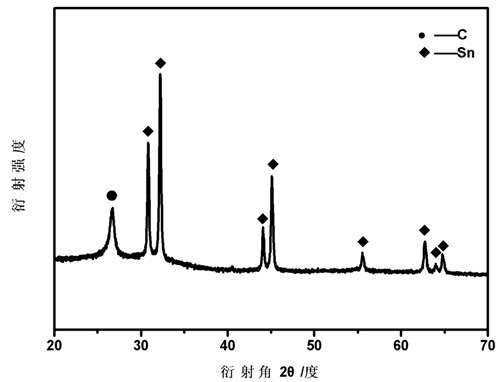

Embodiment 1

[0041] After mixing the tin raw material and the graphite raw material powder, the mass ratio of the carbon raw material to the total raw material is 30%. According to the above ball milling method, the tin-carbon mixed powder after ball milling was obtained, the discharge gas medium is argon, the ball powder mass ratio of the ball and the mixed powder is 30:1, and the ball milling time is 2.5h; then according to the above battery test conditions And steps for charge and discharge test, the first reversible capacity of the prepared Sn-30wt%C composite material is 613mAh / g.

Embodiment 2

[0043] The method of dielectric barrier discharge plasma-assisted ball milling is used to prepare tin-carbon composite materials for lithium-ion battery negative electrodes. The steps are basically the same as in Example 1, except that the raw materials are proportioned according to Sn-Xwt%C, where the value of X For X=50, the mass ratio of the ball powder to the mixed powder is 40:1, and the ball milling time is 5h. The above powders were made into electrode sheets and batteries were assembled for charge and discharge tests. The first reversible capacity of the prepared Sn-50wt%C composite was 480mAh / g.

Embodiment 3

[0045] The method of dielectric barrier discharge plasma-assisted ball milling is used to prepare tin-carbon composite materials for lithium-ion battery negative electrodes. The steps are basically the same as in Example 1, except that the raw materials are proportioned according to Sn-Xwt%C, where the value of X For X=50, the mass ratio of the ball powder to the mixed powder is 50:1, and the ball milling time is 7.5h. The above powders were made into electrode sheets and batteries were assembled for charge and discharge tests. The first reversible capacity of the prepared Sn-50wt%C composite was 497mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com