Fully-mixed granular feed for calves and preparation method thereof

A technology of fully mixed and pelleted feed, applied in animal feed, animal feed, application, etc., can solve problems such as the ratio of roughage to concentrate particles, the particle size of roughage, and the feeding form without establishing clear standards, so as to achieve palatability Good, stimulating rumen development, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] In order to ensure that the above and other features and advantages of the present invention are more obvious and understandable, the following three embodiments are given to further describe the present invention in detail.

[0038] The sources of raw materials are as follows:

[0039] Alfalfa powder: first-grade alfalfa imported from the United States, crushed, and 5-10 mesh parts;

[0040] Puffed corn flour: Harbin Pufan Feed Co., Ltd.;

[0041] Extruded soybeans: Harbin Pufan Feed Co., Ltd.;

[0042] Soybean Meal: Bangji Zhengda Tianjin Grain and Oil Co., Ltd.;

[0043] Bacillus natto: Shandong Baolai Lilai Biotechnology Co., Ltd.;

[0044] Yeast cell wall polysaccharide: Angel Yeast Co., Ltd.;

[0045] Calcium hydrogen phosphate: Sichuan Chuanheng Chemical Co., Ltd.;

[0046] Magnesium Oxide: Yuncheng Baxing Chemical Co., Ltd.;

[0047] Salt: China Salt Tianjin Changlu Salt Industry Company;

[0048] Baking soda: Tongbai Boyuan New Chemical Co., Ltd.;

[00...

Embodiment 1-3

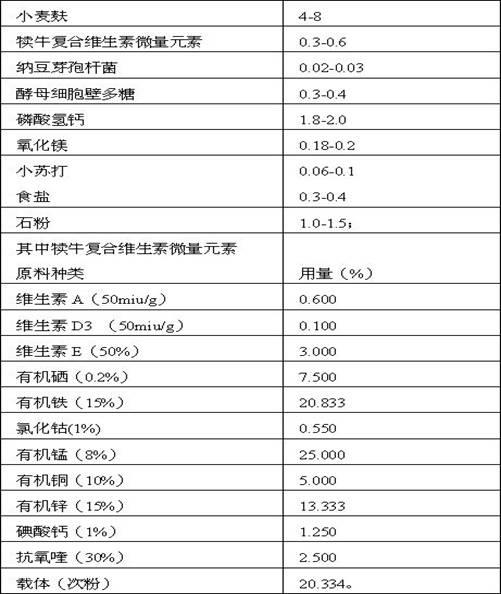

[0051] Formulated by weight by mixing:

[0052] raw material

recipe (1)

Recipe (2)

Recipe (3)

Alfalfa Meal

20

21

23

25

21

20

Puffed Corn Flour

20

22

25

puffed soybeans

4

5

3

22

20

16

wheat bran

4

6

8

calf multivitamin with trace elements

0.5

0.5

0.5

0.02

0.02

0.02

yeast cell wall polysaccharide

0.4

0.4

0.4

1.88

1.88

1.88

0.2

0.2

0.2

baking soda

0.1

0.1

0.1

salt

0.4

0.4

0.4

stone powder

1.5

1.5

1.5

total

100

100

100

[0053] Preparation

[0054] Alfalfa grass powder, corn flour, puffed corn flour, puffed soybeans, soybean meal, calf multivitamins and trace elements, Bacillus natto, yeast cell wall polysaccharide, calcium hydrogen phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com